Two-component polyurethane adhesive and preparation method and application thereof

A two-component polyurethane and adhesive technology, used in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of unstable bonding effect and reduce the surface of WPC materials. It can solve the problems of high energy consumption and process conditions, and achieve the effect of simple and energy-saving sizing process, excellent environmental friendly performance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

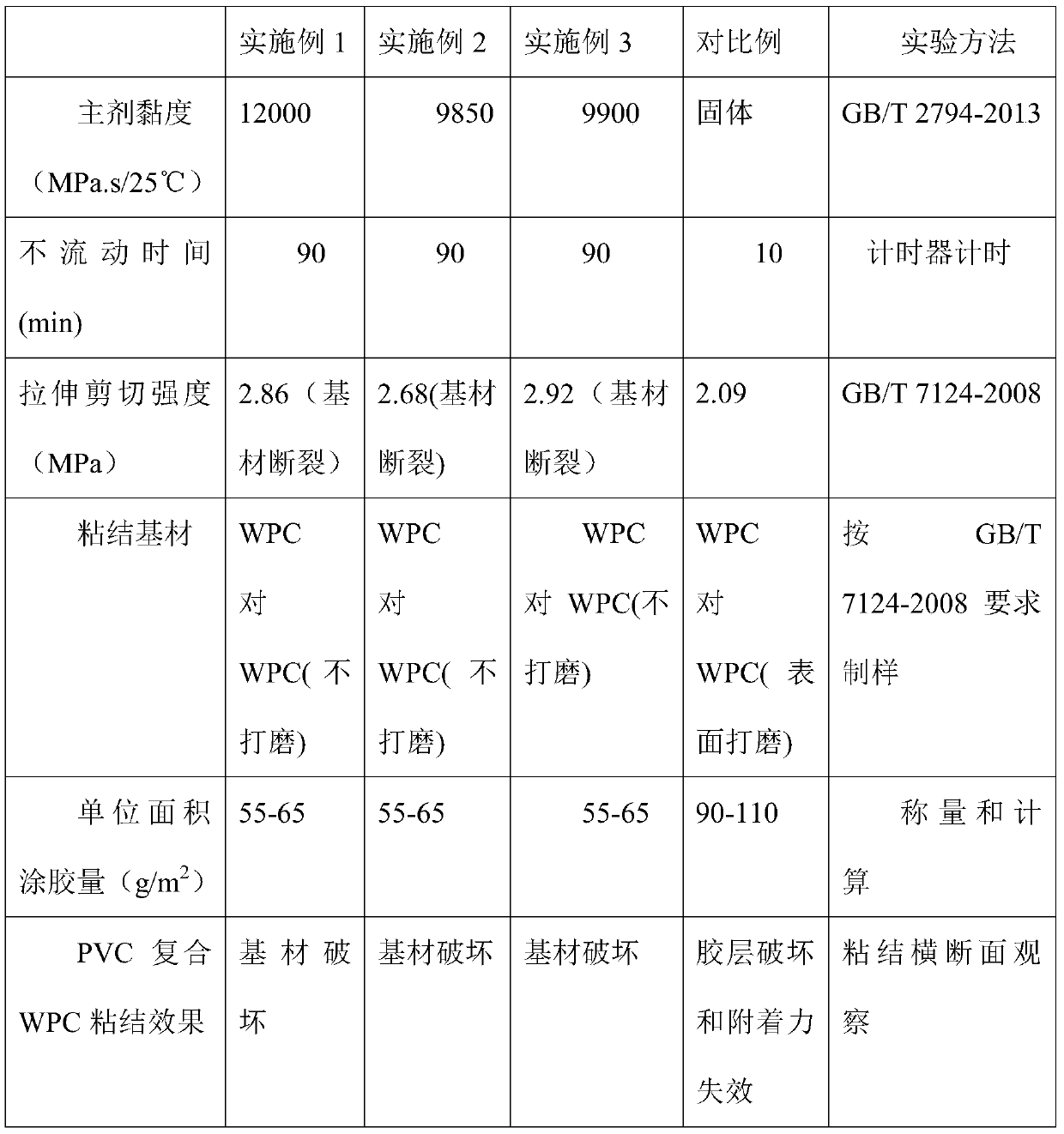

Examples

Embodiment 1

[0029] A kind of preparation method of two-component polyurethane adhesive is as follows:

[0030] (1) Preparation of main ingredients: 10 parts of polyether polyol 4110, 5 parts of polyether polyol DV-125, 10 parts of polyether polyol PPG2000, 15 parts of polyester polyol PDP-70, 1 part of stabilizer B 84805 , 0.5 parts of catalyst POLYCAT 8, 1.5 parts of catalyst DABCO BL 11, 10 parts of calcium sulfate, 40 parts of talcum powder, 5 parts of Solstice zd and 2 parts of deionized water, polyether polyol, polyester polyol, stabilizer, catalyst 1. The foaming agent is fully mixed and stirred at room temperature, then vacuum defoamed until there are no bubbles; add inorganic fillers and mix evenly, vacuum defoam until there are no bubbles, cool down to room temperature; add diluent in proportion and stir evenly to obtain the main agent.

[0031] (2) The curing agent is a self-made isocyanate prepolymer.

[0032] (3) The mixing ratio of main agent and curing agent is 5:1 (mass ra...

Embodiment 2

[0034] A kind of preparation method of two-component polyurethane adhesive is as follows:

[0035] (1) Preparation of main ingredients: 12 parts of polyether polyol SA380, 3 parts of polyether polyol 304, 15 parts of polyether polyol PPG1000, 5 parts of polyether polyol PPG400, 1 part of stabilizer B84804, 1 part of catalyst POLYCAT 8 , 1 part of catalyst DABCO PT 306, 20 parts of alumina, 35 parts of talcum powder, 3 parts of Solstice zd, 2 parts of Genetron 245fa and 2 parts of deionized water, polyether polyol, polyester polyol, stabilizer, catalyst and The foaming agent is fully mixed and stirred at room temperature, and then vacuum defoamed until there are no bubbles; the inorganic filler is added and mixed evenly, vacuum defoamed until there are no bubbles, and the temperature is cooled to room temperature; the diluent is added in proportion and stirred evenly to obtain the main agent.

[0036] (2) The curing agent is a self-made isocyanate prepolymer.

[0037] (3) The ...

Embodiment 3

[0039] A kind of preparation method of two-component polyurethane adhesive is as follows:

[0040] (1) Preparation of main ingredients: 15 parts of polyether polyol SA380, 3 parts of polyether polyol DV-125, 10 parts of polyether polyol PPG2000, 10 parts of polyester polyol AK-7001, 1.5 parts of stabilizer B 84805 , catalyst POLYCAT 8 0.5 parts, catalyst DABCO PT 303 0.5 parts, catalyst DABCO BL 11 1.5 parts, barium sulfate 10 parts, talcum powder 35 parts, zinc oxide 5 parts, Solstice zd 5 parts and deionized water 3 parts, polyether Polyols, polyester polyols, stabilizers, catalysts, and blowing agents are fully mixed and stirred at room temperature, and then vacuum defoamed until there are no bubbles; add inorganic fillers and mix evenly, vacuum defoam until there are no bubbles, and cool down to room temperature; Add the diluent and stir evenly to obtain the main agent.

[0041] (2) The curing agent is a self-made isocyanate prepolymer.

[0042] (3) The mixing ratio of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com