Biochar-mediated solid biofilm anaerobic digestion accelerator preparation device and method thereof

An anaerobic digestion and preparation device technology, which is applied to biochemical equipment and methods, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve problems such as long start-up time, and achieve improved adequacy, rapid enrichment, The effect of shortening the hydraulic retention period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

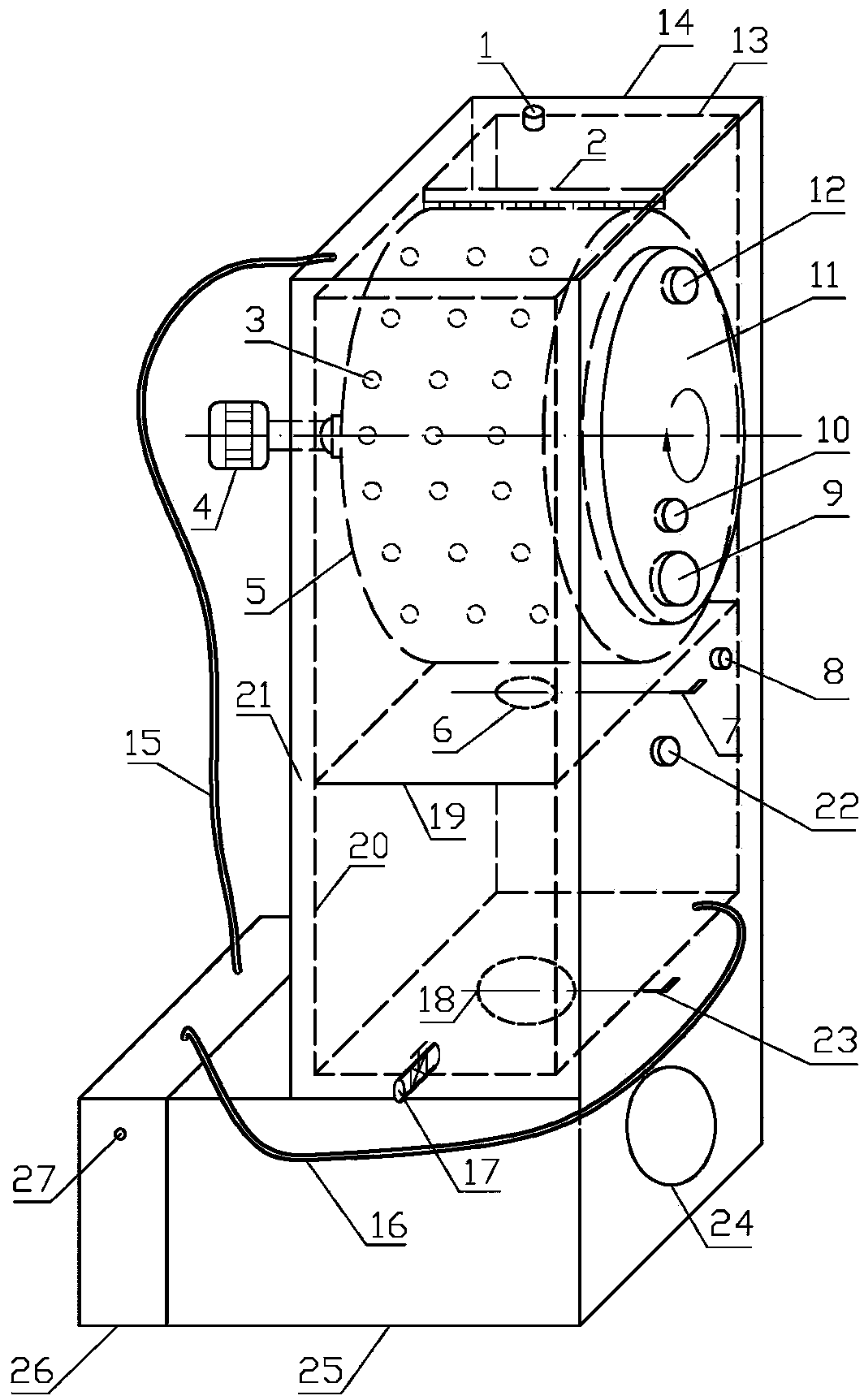

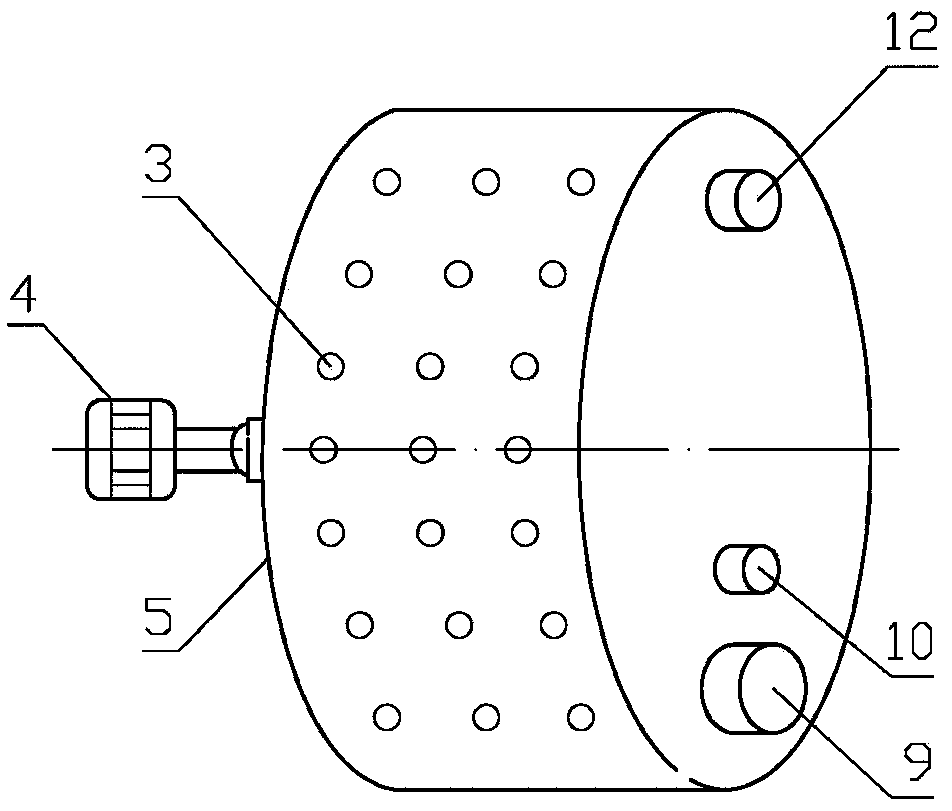

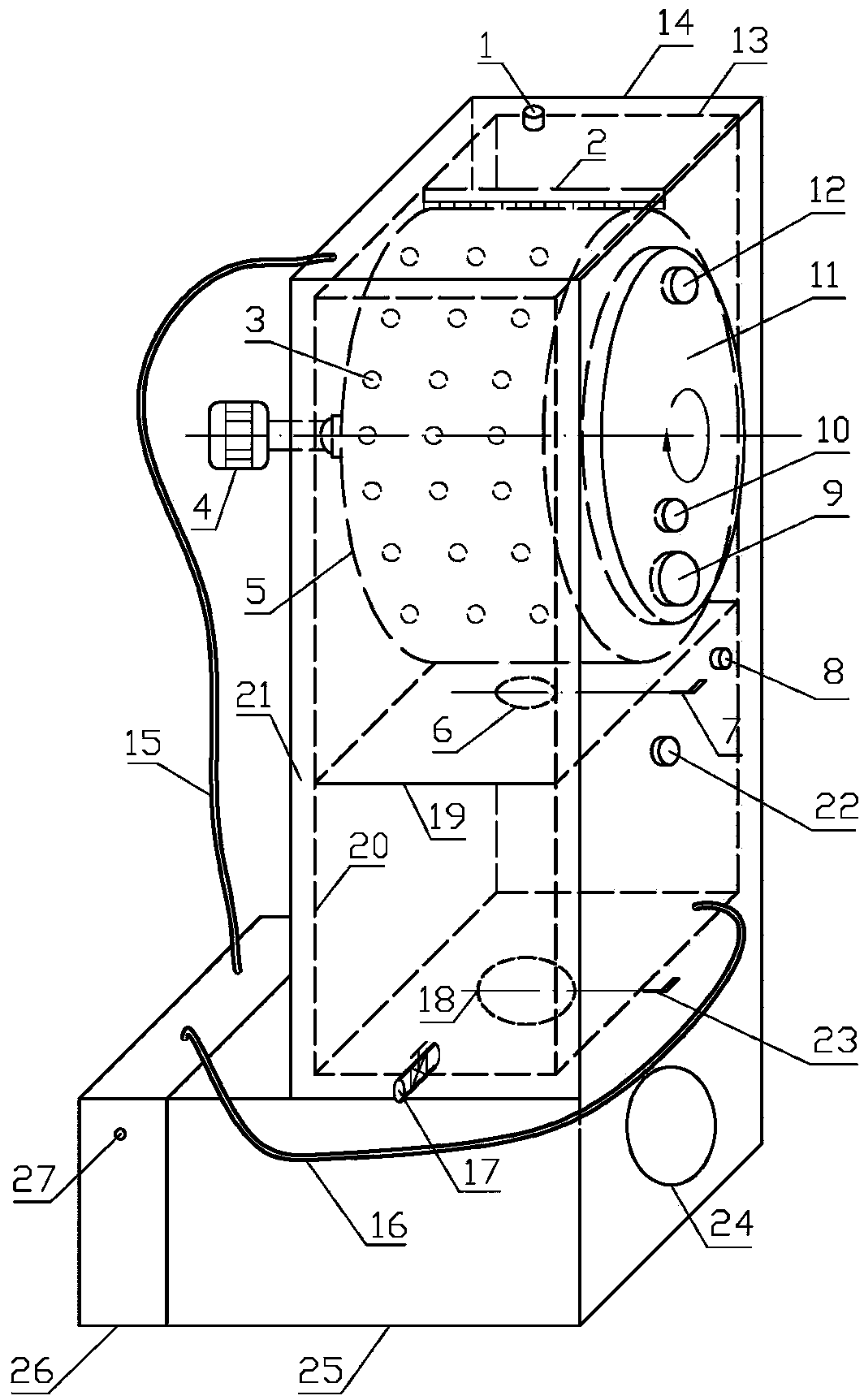

[0060] A biochar-mediated solid biofilm anaerobic digestion accelerator preparation device, comprising a drum 5, a biogas slurry chamber 13, a biofilm culture chamber 20, an outer chamber 14, a constant temperature heater 26 and a vacuum freeze dryer 25; The drum 5 is located in the biogas slurry chamber 13; the biogas slurry chamber 13 is separated from the biofilm culture chamber 20 by a partition 19, and forms a jacket 21 with the outer chamber 14; the partition 19 There is a biogas slurry gate 6, and the biogas slurry gate switch 7 is located at the corresponding position on the outer wall of the outer cavity 14; the heating tube 15 of the constant temperature heater 26 is connected to the upper right end surface of the left wall of the outer cavity 14, and the heat return tube 16 is connected to the The lower right end surface of the right wall of the outer chamber 14; the biofilm gate 18 is provided between the bottom surface of the biofilm culture chamber 20 and the bott...

Embodiment 2

[0074] A preparation method of a biochar-mediated solid biofilm anaerobic digestion accelerator, based on a biochar-mediated solid biofilm anaerobic digestion accelerator preparation device of embodiment 1, comprising the following steps:

[0075] S1 Preparation of anaerobic digestion solid biofilm:

[0076] S1.1 medium preparation:

[0077] Medium: NH 4 Cl 1 g / L, MgCl 2 1 g / L, NaCl 0.5 g / L, K 2 HPO4 0.4 g / L, KH 2 PO4 0.4 g / L, peptone 2 g / L, yeast extract powder 2 g / L, sodium acetate 10 g / L, trace elements 10 mL, vitamin 10 mL, L-cysteine 0.5 g / L, 2‰ edge Azure 2 mL, distilled water 1000 mL (pH 7.0); among them,

[0078] Trace elements (g / L): N (CH2COOH) 3 4.5 (aminoacetic acid), FeCl 2 4H 2 O 0.4, MnCl H 2 O0.1, CoCl 2 ·6H 2 O 0.12, AlK ( SO 4 ) 2 0.01, ZnCl 2 0.1, NaCl 1, CaCl 2 0.02, Na 2 MoO 4 0.01, H 3 BO 3 0.01, NiCl 2 ·6H 2 O 0.42;

[0079] Vitamins (g / L): Biotin 2.0, Thiamine 5.0, Pyridoxine Hydrochloride 10, D-Pantocalcic Acid 5.0, Alp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com