Cobalt-cerium/sepiolite catalyst as well as preparation method and application thereof

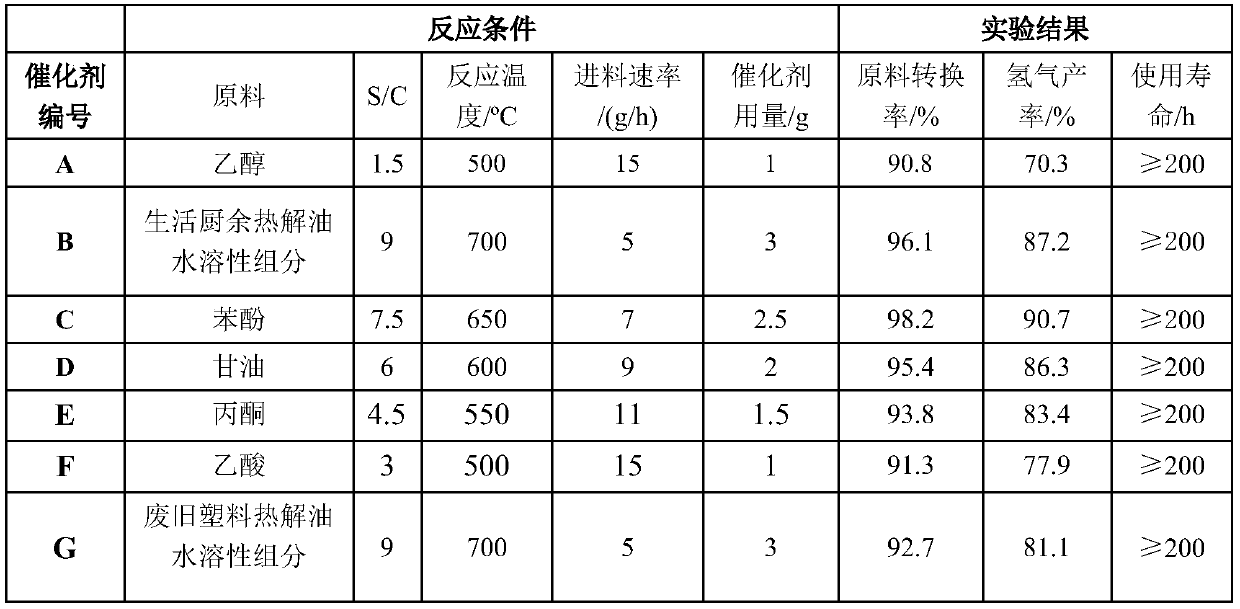

A sepiolite and catalyst technology, which is applied in the field of cobalt-cerium/sepiolite catalyst and its preparation, can solve the problems of unfavorable large-scale industrial application and high price, and achieve enhanced reforming performance and service life, enhanced service life, Effect of improving conversion rate and hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The content of active component cobalt (Co) in the cobalt-cerium / sepiolite catalyst prepared in this embodiment is 5wt.%, the content of additive cerium (Ce) is 3wt.%, and the remaining ingredients are sepiolite. Preparation method as follows:

[0037] Take 10.00 g of sepiolite raw material, add it to 5 mol / L nitric acid, stir it magnetically for 2 hours in a constant temperature water bath at 40°C, then carry out suction filtration, washing, drying, and mechanical crushing to obtain solid powder I; put solid powder I in a tube In a type furnace, it was heated to 400°C at a heating rate of 1°C / min, and then calcined in an air atmosphere for 4 hours to obtain purified sepiolite; weigh 1.2346g Co(NO 3 ) 2 ·6H 2 O, 0.4648g Ce(NO 3 ) 3 ·6H 2 O and 2.9052g cetyltrimethylammonium bromide (surfactant to metal ion molar ratio S / M=1.5) were placed in a 250mL round bottom beaker and dissolved in 100mL deionized water to form solution I. Weigh 4.4043 g of the purified sepiol...

Embodiment 2

[0039] The content of active component cobalt (Co) in the cobalt-cerium / sepiolite catalyst prepared in this embodiment is 15wt.%, the content of additive cerium (Ce) is 24wt.%, and the remaining ingredients are sepiolite. Preparation method as follows:

[0040] Take 10.00 g of sepiolite raw material, add it to 10 mol / L nitric acid, and stir it magnetically for 4 hours under constant temperature water bath at 80°C, then carry out suction filtration, washing, drying, and mechanical crushing to obtain solid powder I; put solid powder I in a tube In a type furnace, heated to 700°C at a heating rate of 4°C / min, and then calcined in an air atmosphere for 2 hours to obtain purified sepiolite; weigh 2.6229g CH 3 COOCo·4H 2 O, 2.5336g CH 3 COOCe·xH 2 O and 4.5626g polysorbate 80 (surfactant and metal ion molar ratio S / M=0.5) were placed in a 250mL round bottom beaker and added to 100mL deionized water to completely dissolve to form solution I. Weigh 2.5046 g of the purified sepioli...

Embodiment 3

[0042] The content of active component cobalt (Co) in the cobalt-cerium / sepiolite catalyst prepared in this embodiment is 10wt.%, the content of additive cerium (Ce) is 8wt.%, and the remaining ingredients are sepiolite. Preparation method as follows:

[0043] Take 10.00 g of sepiolite raw material, add it to 6 mol / L nitric acid, and stir it magnetically for 4 hours under the condition of constant temperature water bath at 55°C, then carry out suction filtration, washing, drying, and mechanical crushing to obtain solid powder I; put solid powder I in a tube In a type furnace, heated to 700°C at a heating rate of 4°C / min, and then calcined in air atmosphere for 1.5h to obtain purified sepiolite; weigh 1.2346g Co(NO 3 ) 2 ·6H 2 O, 0.7373g CH 3 COOCe·xH 2 O and 2.0466g sodium lauryl sulfate (surfactant and metal ion molar ratio S / M=1) were placed in a 250mL round bottom beaker and added to 100mL deionized water to completely dissolve to form solution I. Weigh 4.2595 g of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com