Method for preparing porous carbon material from waste corrugated paper fibers and use of porous carbon material

A technology of porous carbon materials and waste corrugated paper, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of long activation time, corrosion of equipment, pollution of the environment, etc., and achieve good application prospects, high carbon content, The effect of simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

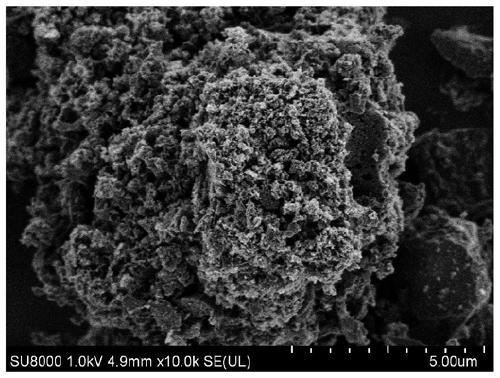

[0033] Dissolve 2g of corrugated paper fiber that has been pulped by a beater and dried in 100ml of a mixed solution of sodium hydroxide and potassium hydroxide with a concentration of 0.03g / ml, then soak and stir the solution at 40°C for 3h, and place it in an oven after soaking 6h, the temperature was set at 110°C; finally, the treated fiber was placed in a tube furnace for carbonization, the carbonization temperature was 1000°C, the heating rate was 10°C / min, and kept for 1h, after taking it out, it was washed and neutralized, and then Drying, the drying temperature is 100°C, and the drying time is 6h; the porous carbon material is obtained after carbonization, and its scanning electron microscope picture is as follows figure 1 As shown, the pores distributed on the surface can be clearly seen and the pore diameter is around nanometers.

Embodiment 2

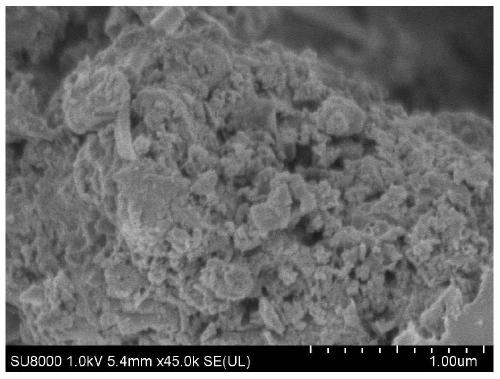

[0035] Dissolve 5g of corrugated fiber in 100ml of a mixed solution of sodium hydroxide and potassium hydroxide with a concentration of 0.05g / ml, then soak and stir the solution at 60°C for 1h, then place it in an oven for 12h after soaking, and set the temperature at 70°C ; Finally, place the treated fiber in a tube furnace for carbonization, the carbonization temperature is 500°C, the heating rate is 5°C / min, and keep warm for 3h, take it out, wash and neutralize it, and then dry it at 70°C ℃, drying time 3h; porous carbon material is obtained after carbonization. Its scanning electron microscope picture is as figure 2 As shown, the pores distributed on the surface can be clearly seen and the pore diameter is around nanometers.

Embodiment 3

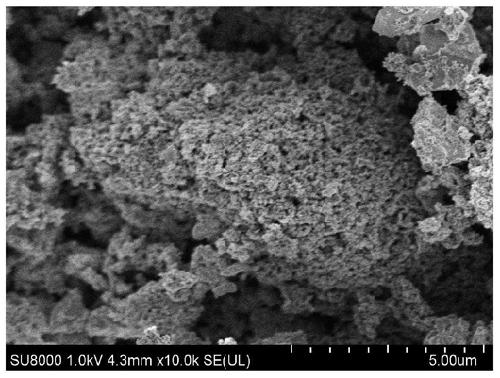

[0037] Dissolve 3g of corrugated fiber in 100ml of a mixed solution of sodium hydroxide and potassium hydroxide with a concentration of 0.04g / ml, then soak and stir the solution at 50°C for 2h, then place it in an oven for 9h after soaking, and set the temperature to 100°C ; Finally, place the treated fiber in a tube furnace for carbonization, the carbonization temperature is 800°C, the heating rate is 8°C / min, and keep it warm for 2h, take it out, wash and neutralize it, and then dry it at 90°C ℃, drying time 5h; porous carbon material is obtained after carbonization. Its scanning electron microscope picture is as image 3 As shown, the pores distributed on the surface can be clearly seen and the pore diameter is around nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com