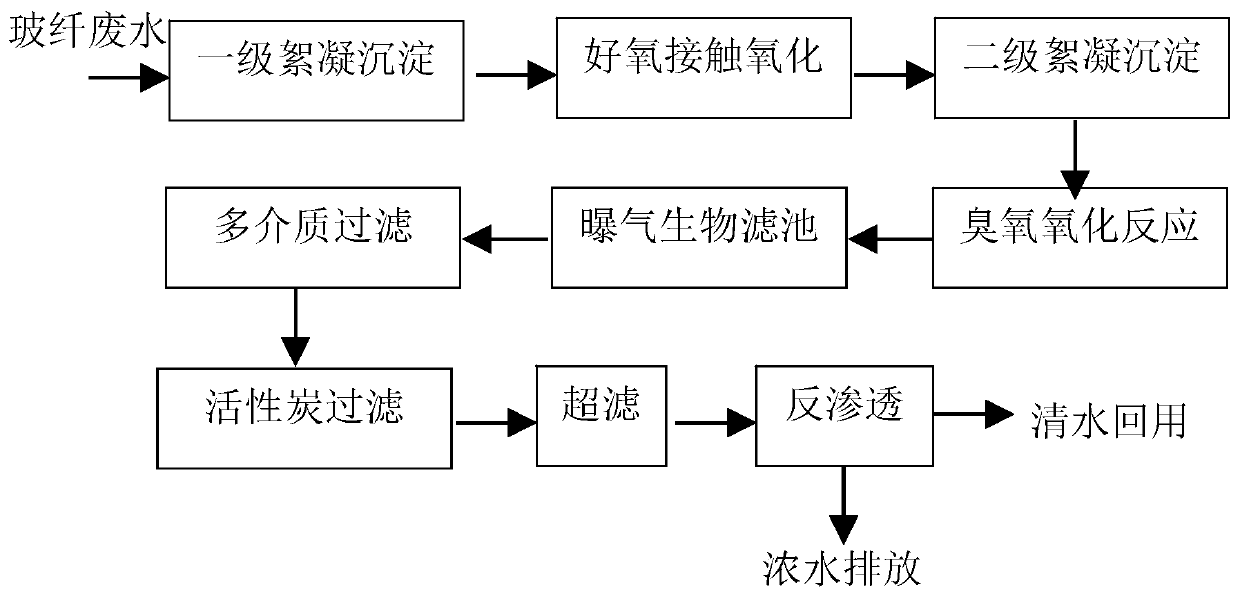

Glass fiber wastewater reusing and processing method and system

A treatment method and a treatment system technology, which are applied in the field of glass fiber wastewater reuse treatment methods and systems, can solve the problems of high frequency of membrane cleaning and low water production rate, and achieve the effect of protection from pollution and efficient reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] use as figure 1 In the treatment system shown, the wastewater from the glass fiber factory is lifted into the regulating tank, and the water quality and quantity are balanced in the regulating tank. (The hydraulic retention time of the regulating tank is 8h, the designed effluent COD: 5000mg / L, chromaticity 600 times) flows into the primary flocculation reaction Pool, add polyaluminum chloride 500mg / L, PAM (polyacrylamide) 5mg / L in the primary flocculation reaction tank, the hydraulic retention time of the flocculation reaction is 16min, after the flocculation reaction, advection sedimentation tank, advection sedimentation tank The surface load is taken as 0.85m 3 / m 2 h, the mud-water separation is carried out in the sedimentation tank, and the clean water enters the aerobic biological treatment system; the aerobic biological treatment system is equipped with soft fillers, a liftable aerator is used, the reaction gas-water ratio is 10:1, and the hydraulic retention ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com