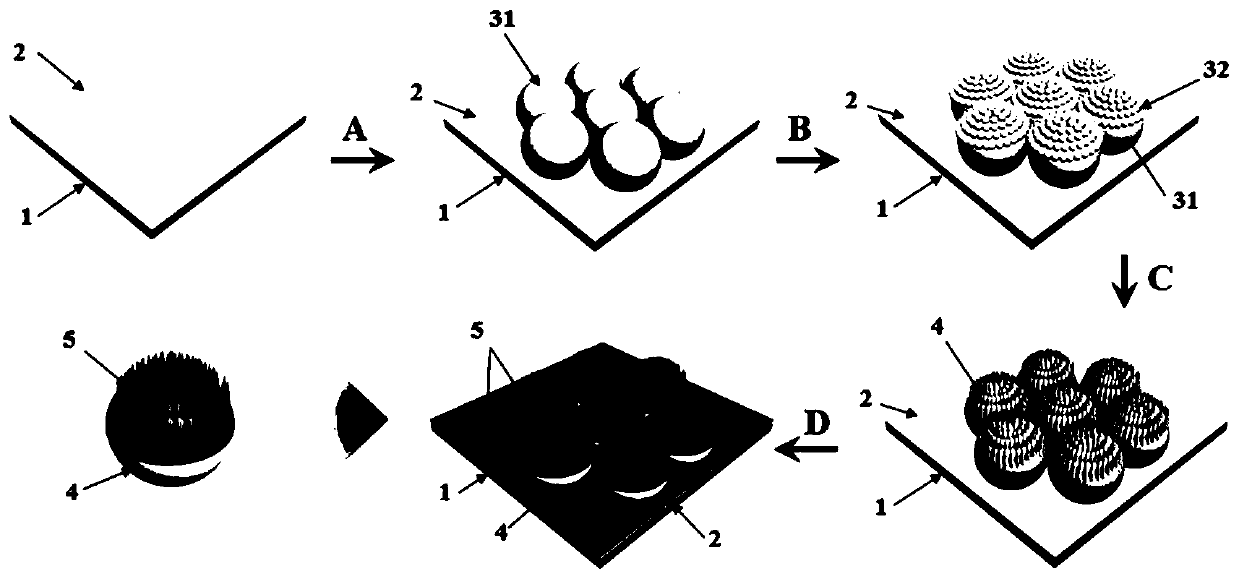

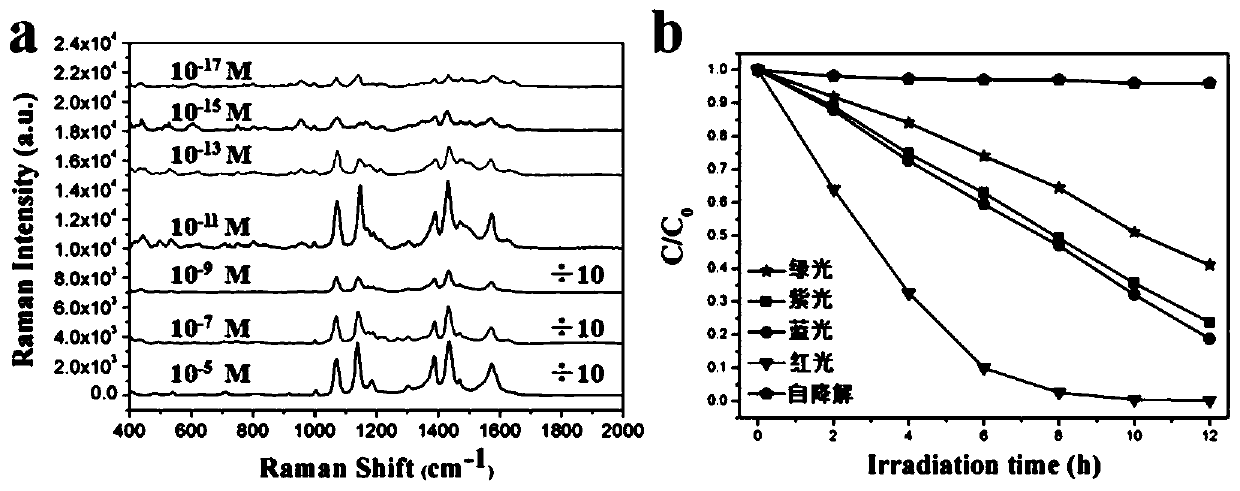

Hierarchical nano-cone array for in-situ monitoring of chemical reactions by surface-enhanced Raman scattering and preparation method thereof

A surface-enhanced Raman and chemical reaction technology, used in Raman scattering, material excitation analysis, etc., can solve the problems of complex synthesis and preparation of nanoparticle composite materials, rarely prepared, and weakened SPR effect of metal cores. Application value and practical potential, high success rate, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of hydrophilic glass sheet

[0037] Use a glass knife to cut the glass slices into 2.5cm long and 2cm wide sizes, and ultrasonicate the cut glass slices with hexane, acetone, ethanol (or isopropanol), and deionized water for 3 minutes, and then wash the slices Put it into a large beaker, add hydrogen peroxide with a mass fraction of 30%, and then slowly add concentrated sulfuric acid with a mass fraction of 98% (volume ratio of concentrated sulfuric acid to hydrogen peroxide is 7:3), heat to boil, adjust the heating power, and keep boiling for 10 minutes to obtain Hydrophilic glass substrate; the resulting hydrophilic glass was rinsed with deionized water for about 5 times, and dried with nitrogen.

Embodiment 2

[0038] Embodiment 2: the preparation of polystyrene film

[0039] Spin-coat the toluene solution of polystyrene with a concentration of 10 mg / mL on the hydrophilic glass sheet substrate obtained by using a desktop homogenizer (3000 rpm, 30 seconds), and then place it in an oven at 60 ° C for 10 minutes , take it out and place it at room temperature to obtain a polystyrene film with a thickness of 20 nm.

Embodiment 3

[0040] Embodiment 3: Preparation of hydrophobic polystyrene microspheres

[0041] At room temperature, add 6 mL of deionized water to 2 mL of 5 wt % polystyrene microsphere dispersion with a diameter of 3 μm, sonicate at 100% power (100 W) for 15 minutes, and then centrifuge at 8900 rpm for 15 minutes to obtain a precipitate Add 6 mL of deionized water to the precipitated product, sonicate, centrifuge, and then repeat this process 8 times. Add 3 mL of ethanol and 3 mL of deionized water to the precipitated product obtained last time, sonicate for 15 minutes, then centrifuge at 8900 rpm for 15 minutes, suck out the supernatant, and add the same volume of ethanol and deionized water to the precipitated product The water mixture was ultrasonically treated and centrifuged in the same way, and this process was repeated 8 times. After the supernatant was drawn for the last time, 1 mL of ethanol and 1 mL of deionized water were added to the precipitated product to obtain a hydrophobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com