Preparation method of silicon dioxide inverse opal hydrogel photonic crystal beads

A technology of photonic crystal microspheres and silica, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the cumbersome preparation method of silica inverse opal hydrogel photonic crystal microspheres and the difficulty of preparing silica nanoparticles , accuracy, sensitivity gap and other issues, to achieve the effect of batch preparation, simplified production process and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

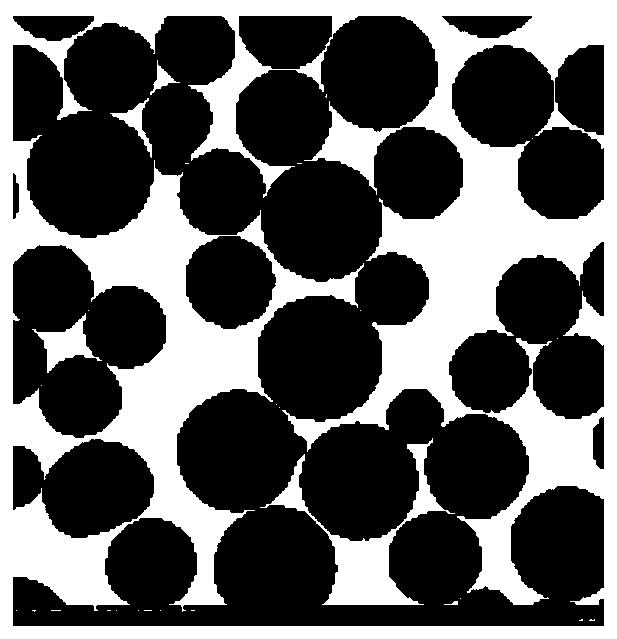

[0044]The preparation steps of the traditional stober method to synthesize silica nanoparticles are as follows:

[0045] References Controlled growth of monodisperse silia sphere in the micronsize range. Synthesize silica nanoparticles with a particle size of 300nm according to the method provided in the literature. The specific steps are:

[0046] Add four milliliters of pentyl esters, four milliliters of ammonium hydroxide, fifty milliliters of saturated alcoholic ammonia solution (mixed solution of ethanol and ammoniacal liquor) in the reaction flask of 250 milliliters, seal bottle mouth with rubber stopper, magnetic stirring condition Two milliliters of tetraethylorthosilicate was added, and the reaction was carried out for ten hours. Wash the silicon spheres with absolute ethanol three to five times to remove unreacted ammonia, ethanol and other impurities in the reaction liquid, resuspend the silica nanoparticles obtained by centrifugation with double distilled water, an...

Embodiment 2

[0048] A method for preparing silica inverse opal hydrogel photonic crystal microspheres, the preparation steps are as follows:

[0049] 1) Synthesis of silica nanoparticles with uniform particle size:

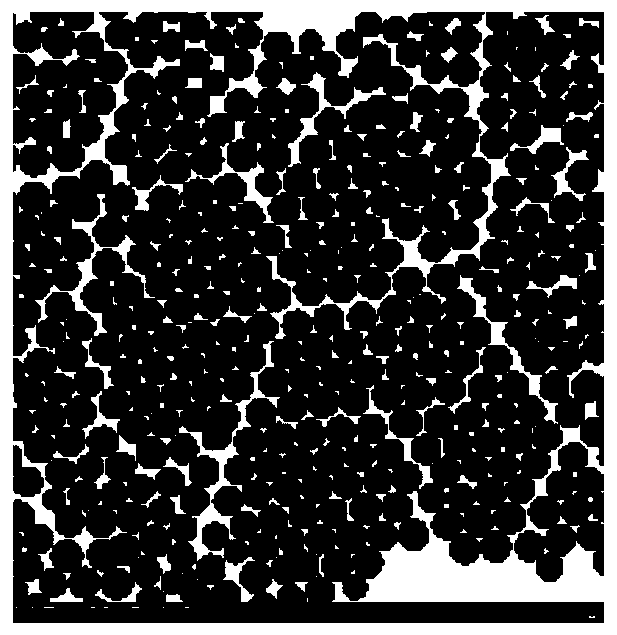

[0050] (1) Take 45mL of absolute ethanol and 5mL of tetraethyl orthosilicate respectively, add the above two substances into the reaction beaker, and then seal the mouth of the beaker with plastic wrap to prevent the volatilization of ethanol. The above solution was ultrasonically treated for 20 minutes to fully disperse tetraethyl orthosilicate in absolute ethanol;

[0051] (2) Take 5mL of ammonia water and 20mL of absolute ethanol respectively, add the above two substances into the reaction beaker, add 15mL of double distilled water, and seal the mouth of the beaker with plastic wrap to prevent the ammonia water and ethanol from volatilizing. under magnetic stirring conditions. Mix the solution thoroughly and evenly;

[0052] (3) Use a syringe pump to inject the solution ...

Embodiment 3

[0064] A method for preparing silica inverse opal hydrogel photonic crystal microspheres, the preparation steps are as follows:

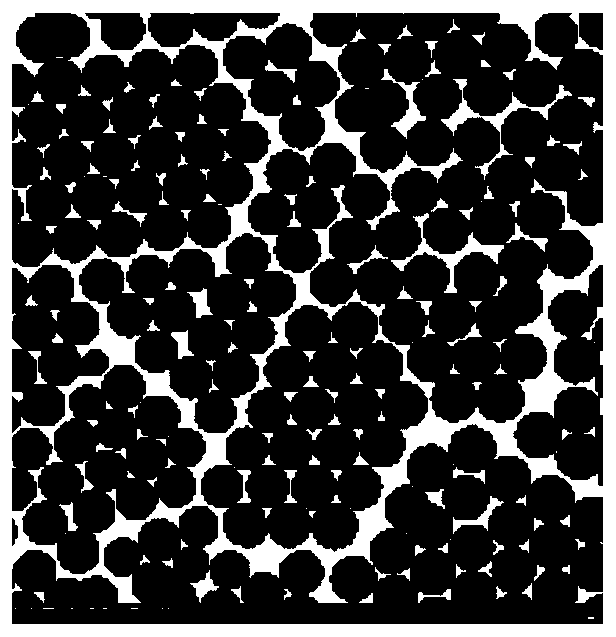

[0065] 1) Synthesis of silica nanoparticles with uniform particle size:

[0066] (1) Take 43mL of absolute ethanol and 7mL of tetraethyl orthosilicate respectively, add the above two substances into the reaction beaker, and then seal the mouth of the beaker with plastic wrap to prevent the volatilization of ethanol. The above solution was ultrasonically treated for 20 minutes to fully disperse tetraethyl orthosilicate in absolute ethanol;

[0067] (2) Take 7mL of ammonia water and 8mL of absolute ethanol respectively, add the above two substances into the reaction beaker, add 15mL of double distilled water, and seal the mouth of the beaker with plastic wrap to prevent the ammonia water and ethanol from volatilizing. under magnetic stirring conditions. Mix the solution thoroughly and evenly;

[0068] (3) Use a syringe pump to inject the solution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com