Organic solar cell adopting functionalized graphene quantum dots as electron transport layer, and preparation method thereof

An electron transport layer, solar cell technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problem of high preparation cost, and achieve the effect of reducing the contact barrier and improving the collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

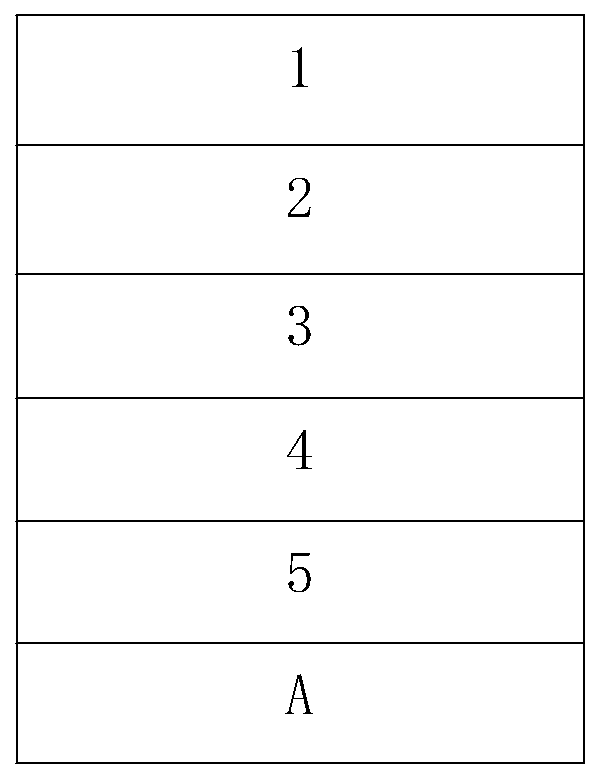

[0028] An anode layer 5 and a hole transport layer 4 were sequentially prepared on the upper surface of the ITO glass substrate, and then a 100 nm thick poly[(2,6-(4,8 -bis(5-(2-ethylhexyl)thiophen-2-yl)benzo[1,2-B:4,5-B']dithiophene)-co-(1,1,3-di(5 -thiophen-2-yl)-5,7-bis(2-ethylhexyl)benzo[1,2-C:4,5-C']dithiophene-4,8-dione)] (referred to as PBDB -T) and (3-(1,1-dicyanomethylene)-1-methyl-indanone)-5,5,11,11-tetrakis(4-hexylphenyl)-dithieno [2,3-d: 2',3'-d']-s-benzobisindeno[1,2-b:5,6-b']-dithiophene) (IT-M for short) film preparation Active layer 3, then functionalized graphene quantum dot solution (concentration of functionalized graphene quantum dots in the solution is 2mg / ml,) is spin-coated on the surface of photoactive layer 3, and the thin film that forms uniform thickness range is 100nm is functionalized then The graphene quantum dots are annealed to obtain the electron transport layer 2, and then transferred to the evaporation system to prepare the cathode layer 1...

Embodiment 2

[0030] With reference to Example 1, the difference is: the functionalized graphene quantum dot solution (the concentration of the functionalized graphene quantum dot in the solution is 100mg / ml,) is spin-coated on the surface of the photoactive layer 3 to form a uniform thickness range of 1nm. film. The I-V test was carried out on the obtained battery, and the circuit current of the device was 16.65mA / cm 2 , the open circuit voltage is 0.91V, the fill factor is 68.84%, and the photoelectric conversion efficiency is 10.43%.

Embodiment 3

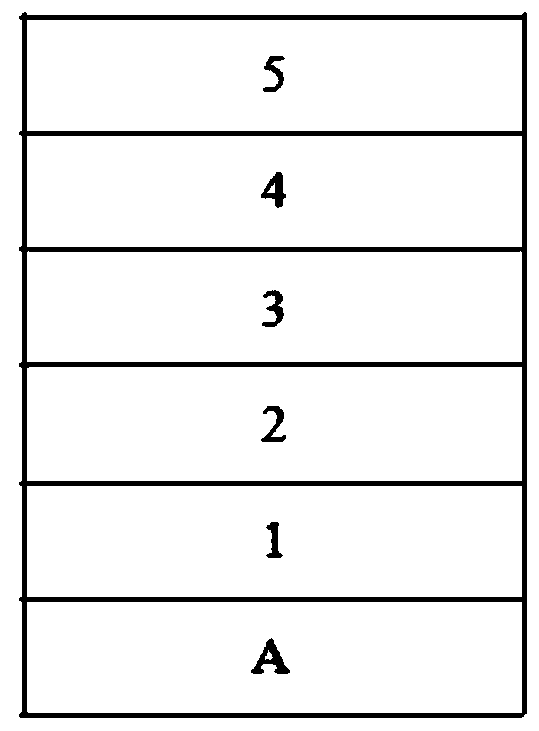

[0032] The cathode layer is prepared on the upper surface of the ITO glass substrate, and the solution of the functionalized graphene quantum dots (the concentration of the functionalized graphene quantum dots in the solution is 0.01mg / ml) is spin-coated on the surface of the cathode layer to form a uniform thickness ranging from 100nm thin film; then the functionalized graphene quantum dots are annealed to obtain the electron transport layer, and then the electron transport layer is spin-coated with a 100nm thick component ratio of 1:1 PBDB-T:IT-M thin film to prepare the photoactive layer. Then prepare a hole transport layer on the other side of the photoactive layer away from the cathode, and then transfer to an evaporation system to evaporate an anode on the surface of the hole transport layer to prepare an anode layer, and prepare an inverted structure of an organic solar cell such as figure 2 As shown, the battery includes a cathode layer 1, an electron transport layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com