Quantum dot dispersion, spontaneous emission photosensitive resin composition containing same, color filter manufactured using same, and image display device

A photosensitive resin and quantum dot technology, which is applied in the field of self-luminous photosensitive resin composition, color filter and image display device, can solve the problems of poor dispersion characteristics, inability to be patterned, and inability to apply color filters, etc. Achieve excellent luminous properties, excellent luminous properties, and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0168] Manufacturing example 1: Synthesis of InP / ZnS core-shell quantum dot particles

[0169] Fabrication of InP nuclear quantum dots

[0170] Add 0.4mmol (0.058g) of indium acetate (Indium acetate), 0.6mmol (0.15g) of palmitic acid (0.15g), and 20mL of 1-octadecene into the reactor, and heat to 120°C under vacuum. After 1 hour, the atmosphere in the reactor was switched to nitrogen. After heating to 280°C, quickly inject a mixed solution of 0.2mmol (58uL) of tris(trimethylsilyl)phosphine (TMS3P) and 1.0mL of trioctylphosphine, and react for 20 minutes. Acetone was added to the reaction solution rapidly cooled to normal temperature, and the precipitate obtained by centrifugation was dispersed in toluene. The obtained InP semiconductor nanocrystal shows the UV first absorption maximum wavelength of 560-590nm.

[0171] Fabrication of InP / ZnS Core-Shell Quantum Dots

[0172] Add 2.4mmol (0.448g) of zinc acetate, 4.8mmol of oleic acid, and 20mL of trioctylamine into the ...

manufacture example 2

[0174] Production Example 2: Synthesis of Alkali-Soluble Resin

[0175] A flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction tube was prepared, and on the other hand, 45 parts by weight of N-benzylmaleimide, 45 parts by weight of methacrylic acid, tricyclic methacrylic acid After 10 parts by weight of decyl ester, 4 parts by weight of tert-butyl peroxy-2-ethylhexanoate, and 40 parts by weight of propylene glycol monomethyl ether acetate (hereinafter referred to as PGMEA), they were stirred and mixed to prepare monomer drops. To the funnel, add 6 parts by weight of n-dodecanemercaptan and 24 parts by weight of PGMEA, stir and mix to prepare a chain transfer agent dropping funnel. Thereafter, 395 parts by weight of PGMEA was introduced into the flask, and the atmosphere in the flask was replaced with nitrogen from air, and then the temperature of the flask was raised to 90° C. while stirring. Next, the monomer and ...

manufacture example 3

[0176] Production Example 3: Production of Quantum Dot Dispersion

[0177] The quantum dot dispersion (A') was produced according to the composition of the following Table 1. At this time, the first solvents were as shown in the following Table 2.

[0178] [Table 1]

[0179]

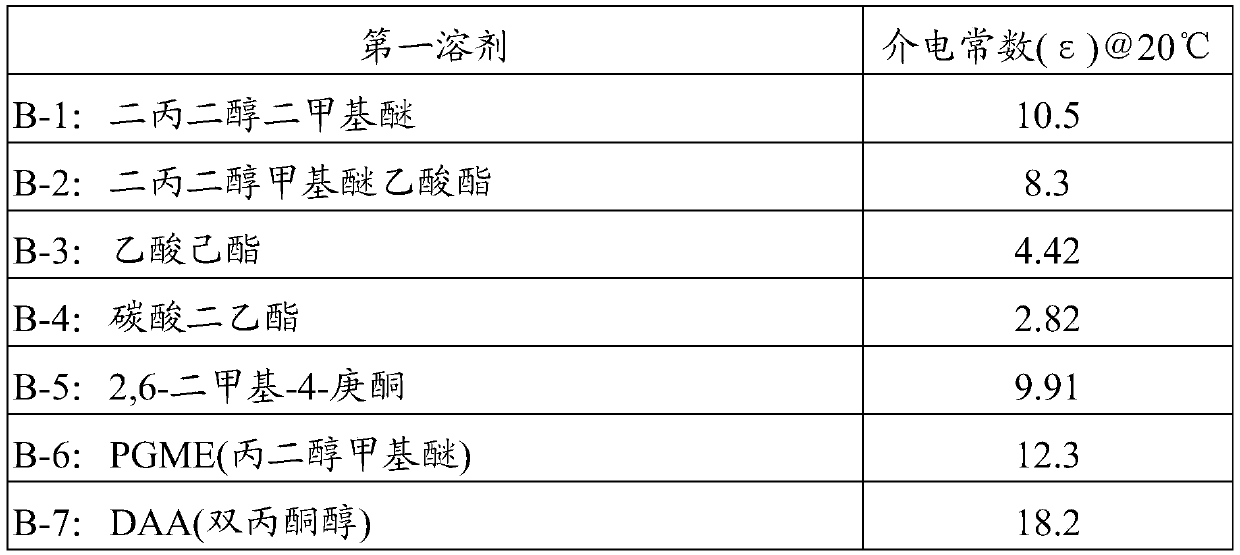

[0180] [Table 2]

[0181]

[0182] Examples and Comparative Examples: Production of Self-luminous Photosensitive Resin Compositions

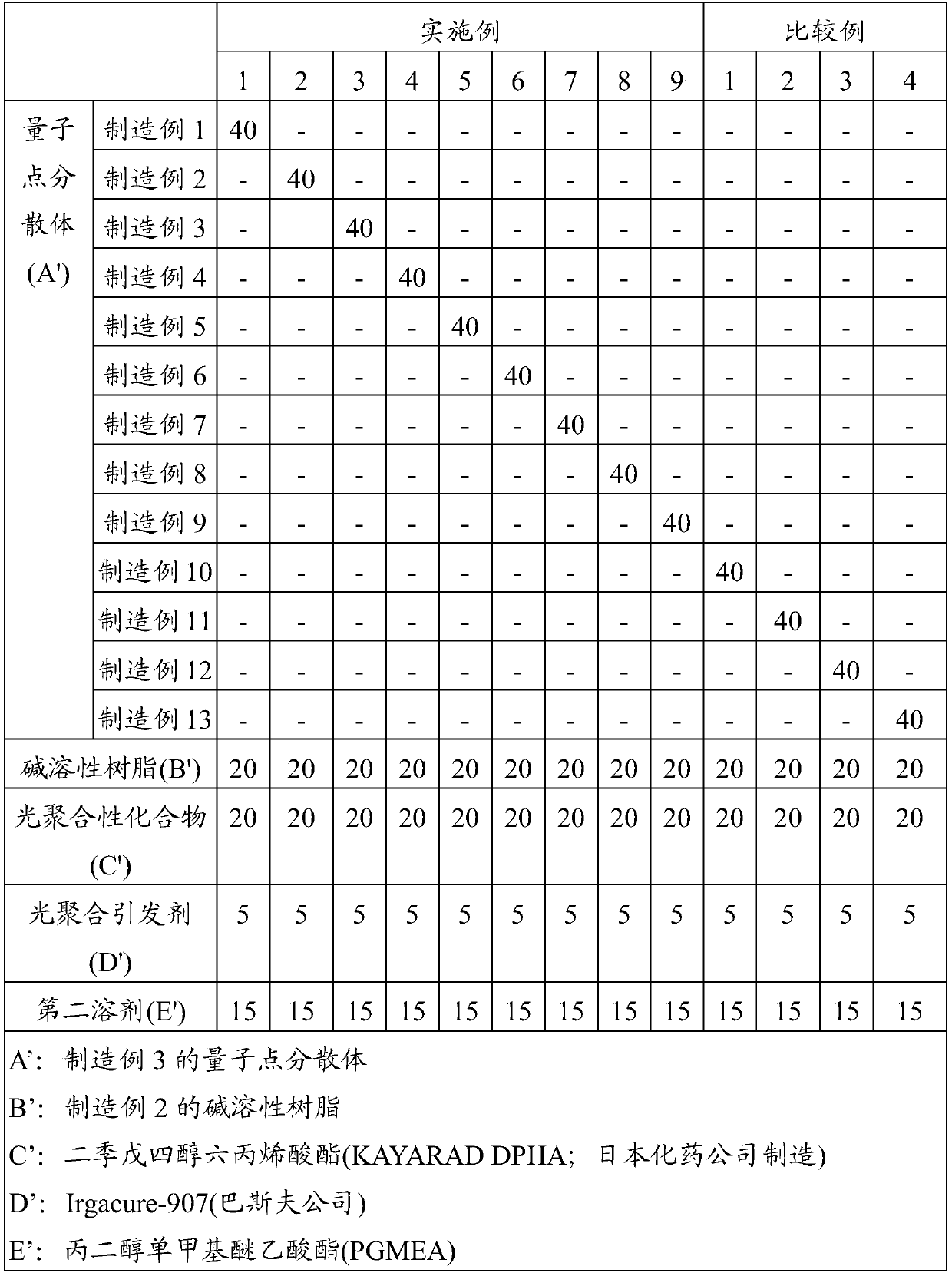

[0183] The self-luminous photosensitive resin compositions of Examples and Comparative Examples were produced according to the compositions in Table 3 below.

[0184] [table 3]

[0185]

[0186] Manufacture of color filters (glass substrates)

[0187] A color filter was manufactured using the self-luminous photosensitive resin composition manufactured by the said Example and the comparative example. Specifically, each self-luminous photosensitive resin composition was coated on a glass substrate by a spin coating method, then placed on a hot plate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com