Preparation and application of magnetic conductive polymer/sepiolite/humic acid composite microsphere

A conductive polymer, composite microsphere technology, applied in silicon compounds, alkali metal compounds, water/sludge/sewage treatment, etc., can solve the problems of poor selectivity, low adsorption efficiency, difficult recovery, etc., to achieve controllable conditions, The effect of strong adsorption capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

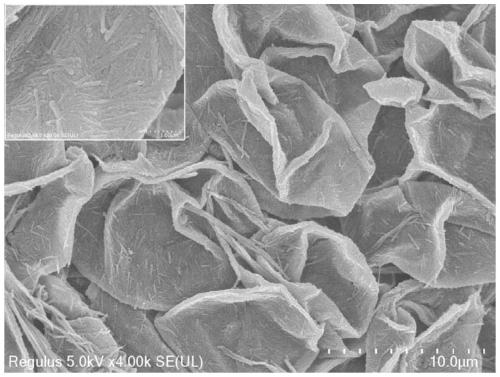

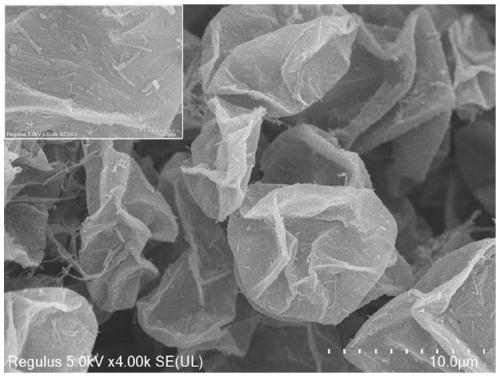

Image

Examples

Embodiment 1

[0024] Take a clean beaker, weigh 560g of water in the beaker, disperse 1.6g of sepiolite powder into the water to obtain a sepiolite dispersion; take another clean beaker, weigh 200g of water in the beaker, and use 1mol / L 0.16g of humic acid powder was dissolved therein to obtain a humic acid aqueous solution; the sepiolite dispersion was mixed with the humic acid aqueous solution, and after stirring for 30min, 40g of 1mol / L was added thereto hydrochloric acid solution, stirred for 10 minutes, and left to stand for 20 minutes to obtain system A; take another clean beaker, add 184g of cyclohexane to it, and ultrasonically disperse 16g of magnetic iron ferric oxide nanoparticles in cyclohexane to obtain System B; mix system B and system A, and shear under a high-speed shear for 3 minutes to obtain a Pickering emulsion; drop 3.2 g of aniline monomer into the prepared Pickering emulsion, stir mechanically for 15 minutes, and 250 g of 2.5 mol / L hydrochloric acid aqueous solution d...

Embodiment 2

[0028] Take a clean beaker, weigh 560g of water in the beaker, disperse 1.6g of sepiolite powder into the water to obtain a sepiolite dispersion; take another clean beaker, weigh 200g of water in the beaker, and use 1mol / L 0.16g of humic acid powder was dissolved therein to obtain a humic acid aqueous solution; the sepiolite dispersion was mixed with the humic acid aqueous solution, and after stirring for 30min, 40g of 1mol / L was added thereto hydrochloric acid solution, stirred for 10 minutes, and left to stand for 20 minutes to obtain system A; take another clean beaker, add 184g of cyclohexane to it, and ultrasonically disperse 16g of magnetic iron ferric oxide nanoparticles in cyclohexane to obtain System B; mix system B and system A, and shear under a high-speed shear for 3 minutes to obtain a Pickering emulsion; drop 6.4 g of aniline monomer into the prepared Pickering emulsion, stir mechanically for 15 minutes, and 250g of 2.5mol / L hydrochloric acid aqueous solution tha...

Embodiment 3

[0032] Take a clean beaker, weigh 560g of water in the beaker, disperse 1.6g of sepiolite powder into the water to obtain a sepiolite dispersion; take another clean beaker, weigh 200g of water in the beaker, and use 1mol / L 0.16g of humic acid powder was dissolved therein to obtain a humic acid aqueous solution; the sepiolite dispersion was mixed with the humic acid aqueous solution, and after stirring for 30min, 40g of 1mol / L was added thereto hydrochloric acid solution, stirred for 10 minutes, and left to stand for 20 minutes to obtain system A; take another clean beaker, add 184g of cyclohexane to it, and ultrasonically disperse 16g of magnetic iron ferric oxide nanoparticles in cyclohexane to obtain System B; mix system B and system A, and shear under a high-speed shear for 3 minutes to obtain a Pickering emulsion; drop 9.6 g of aniline monomer into the prepared Pickering emulsion, stir mechanically for 15 minutes, and 250 g of 2.5 mol / L hydrochloric acid aqueous solution d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com