Mining sewage treatment method

A treatment method and technology for mining sewage, applied in mining wastewater treatment, adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as large amount of flocculant, secondary pollution of water body, vicious cycle, etc., to achieve Improve the adsorption performance, strong electricity neutralization ability, and improve the effect of flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

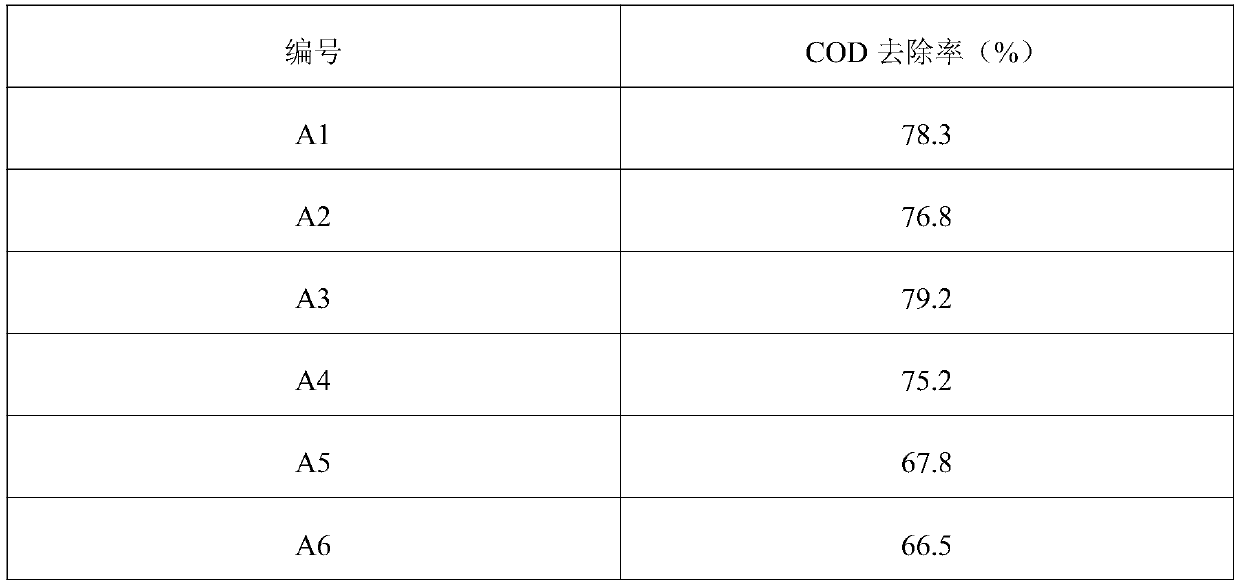

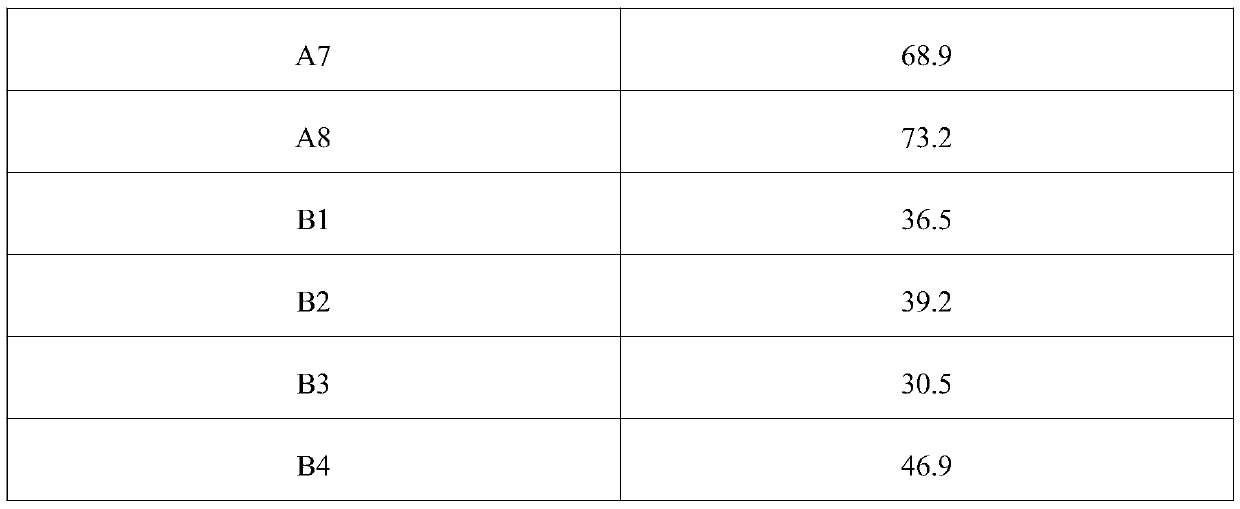

Examples

preparation example 1

[0056] A) Add 0.1mol of ferric chloride and 0.8mol of aluminum chloride into 1L of water and mix to prepare mixed solution M1;

[0057] B) Under the condition of magnetic stirring, add 200 mL of sodium hydroxide aqueous solution with a concentration of 0.8 mol / L dropwise at a rate of 50 drops / min to 1 L of the mixed solution M1, and then place it under the condition of a stirring rate of 200 r / min for 20 h Afterwards, heat and concentrate at 60°C, then dry and grind at 120°C to obtain cured product M2;

[0058] C) Under the condition that the temperature is 100°C, place the zeolite in a 0.8mol / L ammonium nitrate solution and soak it once for 2 hours, then take it out, then place it in a 1.2mol / L ammonium nitrate solution and soak it for a second time for 4 hours, Then take it out and soak it three times in 0.8mol / L ammonium nitrate solution for 2 hours, take it out, wash it with clean water and dry it, and put it in 0.5mol / L sodium chloride aqueous solution under the condition...

Embodiment 2

[0061] A) Add 0.4mol of ferric chloride and 1.5mol of aluminum chloride into 1L of water and mix to prepare mixed solution M1;

[0062] B) Under magnetic stirring conditions, add 300mL of sodium hydroxide aqueous solution with a concentration of 1.2mol / L dropwise to 1L of mixed solution M1 at a rate of 100 drops / min, and then place it for 0h at a stirring rate of 300r / min. After that, heat and concentrate at 80°C, then dry and grind at 140°C to obtain cured product M2;

[0063] C) Under the condition that the temperature is 100° C., place the zeolite in a 1.2 mol / L ammonium nitrate solution and soak for 2 hours once, take it out, and place it in a 1.2 mol / L ammonium nitrate solution for a second immersion for 4 hours. Then take it out and soak it three times in 1.2mol / L ammonium nitrate solution for 2 hours, take it out, wash it with clean water and dry it, and put it in 0.8mol / L sodium chloride aqueous solution under the condition of stirring speed of 200r / min. 6h, obtained ...

Embodiment 3

[0066] A) Add 0.3mol of ferric chloride and 1.2mol of aluminum chloride into 1L of water and mix to prepare mixed solution M1;

[0067] B) Under magnetic stirring conditions, add 240mL of sodium hydroxide aqueous solution with a concentration of 1mol / L dropwise to 1L of mixed solution M1 at a rate of 80 drops / min, and then place it under the condition of a stirring rate of 240r / min for 24h , then heated and concentrated at 70°C, and then dried and ground at 130°C to obtain a cured product M2;

[0068] C) Under the condition that the temperature is 90°C, place the zeolite in the ammonium nitrate solution with a concentration of 1 mol / L for 3 hours, take it out, then place it in the 1 mol / L ammonium nitrate solution for a second time for 3 hours, and then take it out After three immersions in 1 mol / L ammonium nitrate solution for 3 hours, take it out, wash it with clean water and dry it, and then soak it in 0.6 mol / L sodium chloride aqueous solution for 5 hours under the conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com