High-strength safety glass and preparation process thereof

A technology of safety glass and preparation process, which is applied in the direction of glass manufacturing equipment, manufacturing tools, glass molding, etc., which can solve the problems that it is difficult to meet market demand and use requirements, so as to improve transparency and heat resistance, and enhance mechanical properties. Strength, the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

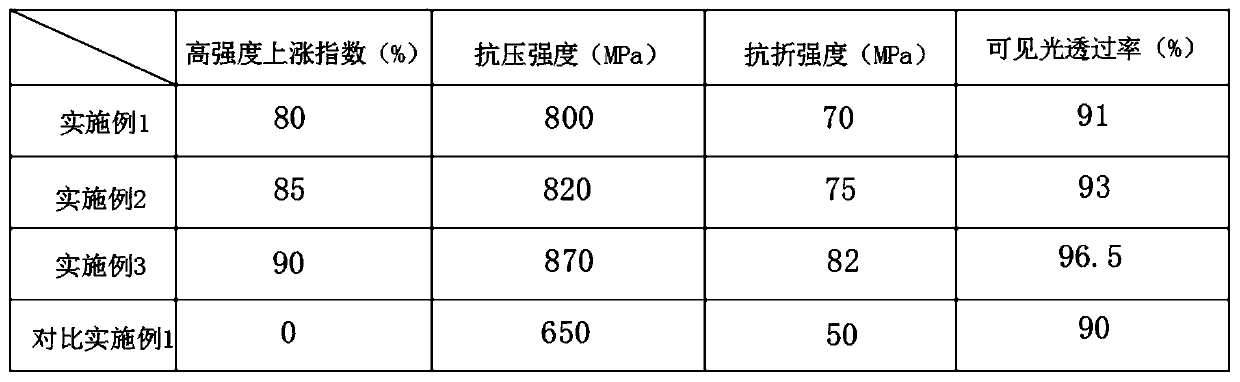

Examples

Embodiment 1

[0024] A high-strength safety glass. The raw materials of the high-strength safety glass are composed by weight: 35 parts of quartz sand, 9 parts of borax, 12 parts of soda ash, 19 parts of broken glass, 8 parts of dolomite, 10 parts of fluorite, three 1 part of antimony oxide, 10 parts of lead oxide, 12 parts of nickel oxide, 1 part of cobalt sulfide, 2 parts of tackifier, 1 part of plasticizer, and 5 parts of photosensitizer.

[0025] Further, the tackifier adopts one of meth or acrylic acid.

[0026] Still further, the plasticizer is one or both of dioctyl phthalate or dibutyl phthalate.

[0027] Still further, the photosensitizer is selected from benzoin ether or benzoin butyl ether.

[0028] Still further, a high-strength safety glass and its preparation process, the preparation process is the following steps:

[0029] S1. Raw material grinding: put a certain amount of quartz sand, broken glass, dolomite and fluorite into a ball mill, and ball mill at a speed of 250-300...

Embodiment 2

[0038] A high-strength safety glass. The raw materials of the high-strength safety glass are composed by weight: 45 parts of quartz sand, 14 parts of borax, 20 parts of soda ash, 30 parts of broken glass, 15 parts of dolomite, 21 parts of fluorite, three 3 parts of antimony oxide, 15 parts of lead oxide, 18 parts of nickel oxide, 5 parts of cobalt sulfide, 10 parts of tackifier, 5 parts of plasticizer, and 12 parts of photosensitizer.

[0039] Further, the tackifier adopts one of meth or acrylic acid.

[0040] Still further, the plasticizer is one or both of dioctyl phthalate or dibutyl phthalate.

[0041] Still further, the photosensitizer is selected from benzoin ether or benzoin butyl ether.

[0042] Still further, a high-strength safety glass and its preparation process, the preparation process is the following steps:

[0043] S1. Raw material grinding: put a certain amount of quartz sand, broken glass, dolomite and fluorite into a ball mill, and ball mill at a speed of ...

Embodiment 3

[0052] A kind of high-strength safety glass, the raw material of high-strength safety glass is composed by weight: 40 parts of quartz sand, 10 parts of borax, 16 parts of soda ash, 25 parts of broken glass, 12 parts of dolomite, 15 parts of fluorite, three 2 parts of antimony oxide, 13 parts of lead oxide, 16 parts of nickel oxide, 3 parts of cobalt sulfide, 7 parts of tackifier, 3 parts of plasticizer, and 9 parts of photosensitizer.

[0053] Further, the tackifier adopts one of meth or acrylic acid.

[0054] Still further, the plasticizer is one or both of dioctyl phthalate or dibutyl phthalate.

[0055] Still further, the photosensitizer is selected from benzoin ether or benzoin butyl ether.

[0056] Still further, a high-strength safety glass and its preparation process, the preparation process is the following steps:

[0057] S1. Raw material grinding: put a certain amount of quartz sand, broken glass, dolomite and fluorite into a ball mill, and ball mill at a speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com