Production method of tomato-derived water-soluble lycopene

A lycopene and water-soluble technology, which is applied in the field of preparation of water-soluble lycopene, can solve the problems of weakened surface and internal penetration, long time required for implementing the process, and difficult removal of squalene, etc., so as to shorten the process Excellent operating cost and operating time, excellent economic effects, and excellent energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention relates to a preparation method of water-soluble lycopene derived from tomatoes, which comprises an alkali reaction step and a salting-out crystallization step.

[0035] Specifically, the present invention relates to a method for preparing water-soluble lycopene, which uses alkali hydroxide ions to hydrolyze refractory cellulose in tomatoes, which is difficult to remove by conventional decomposition methods or extraction methods, for the hydrolyzate Implement salting out and crystallization to obtain water-soluble lycopene.

[0036] So far, lycopene extraction methods have been proposed, including organic solvent extraction, supercritical extraction using supercritical fluid, column extraction, etc., but the problem with these methods is that the organic solvent is mainly used As an extraction solvent or auxiliary solvent, the process of removing the corresponding solvent after extraction is required, and it is difficult to produce high-purity lycopene.

...

preparation example

[0063] Preparation example: extracting lycopene from tomato

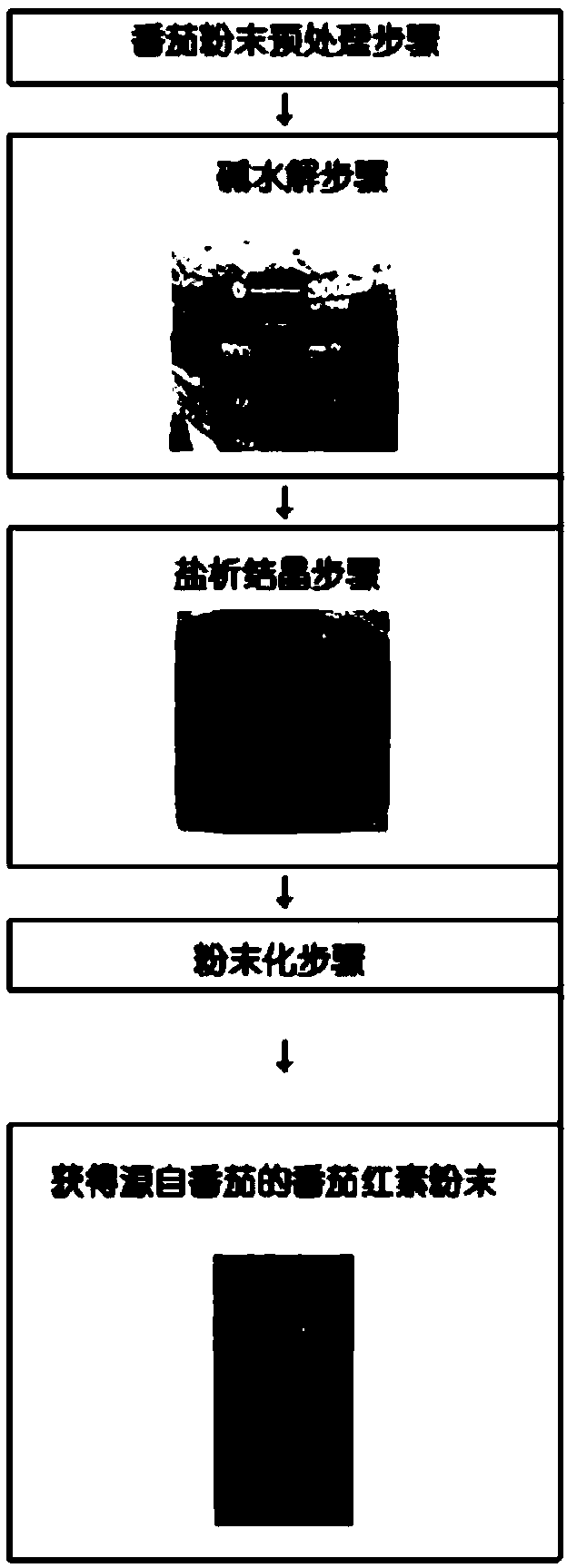

[0064] The method for extracting lycopene from tomato of the present invention is described in figure 1 method implementation. said figure 1 It is a preparation flow diagram showing the method for obtaining water-soluble lycopene derived from tomatoes related to an embodiment of the present invention, and the present invention includes tomato powder pretreatment step (S1), alkali hydrolysis step (S2) and salting out crystallization Step (S3) and powdering step (S4).

[0065] First, 100g of tomato powder (made in Spain) with a particle size of 1mm to 5mm was stirred into 500g of purified water to disperse it, and then left at room temperature (10°C to 20°C) for 2 hours to swell (raw material pretreatment step, S1).

[0066] After the swelling of the tomato powder was completed, 10 g of KOH and 1 kg of purified water were added for hydrolysis at 90° C. for 2 hours. After the hydrolysis, the remaining unreacted re...

Embodiment

[0069] Example: Confirmation of Lycopene Yield Based on Base Type

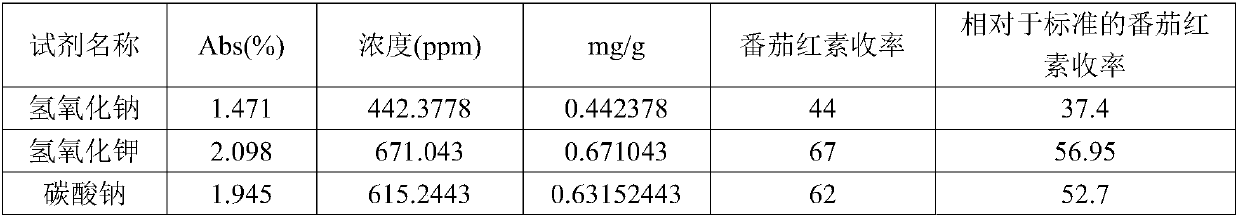

[0070] In order to prepare according to the method of the above-mentioned preparation example and confirm the optimal base for preparing tomato-derived lycopene, sodium hydroxide, potassium hydroxide and sodium carbonate were respectively treated as bases to prepare lycopene.

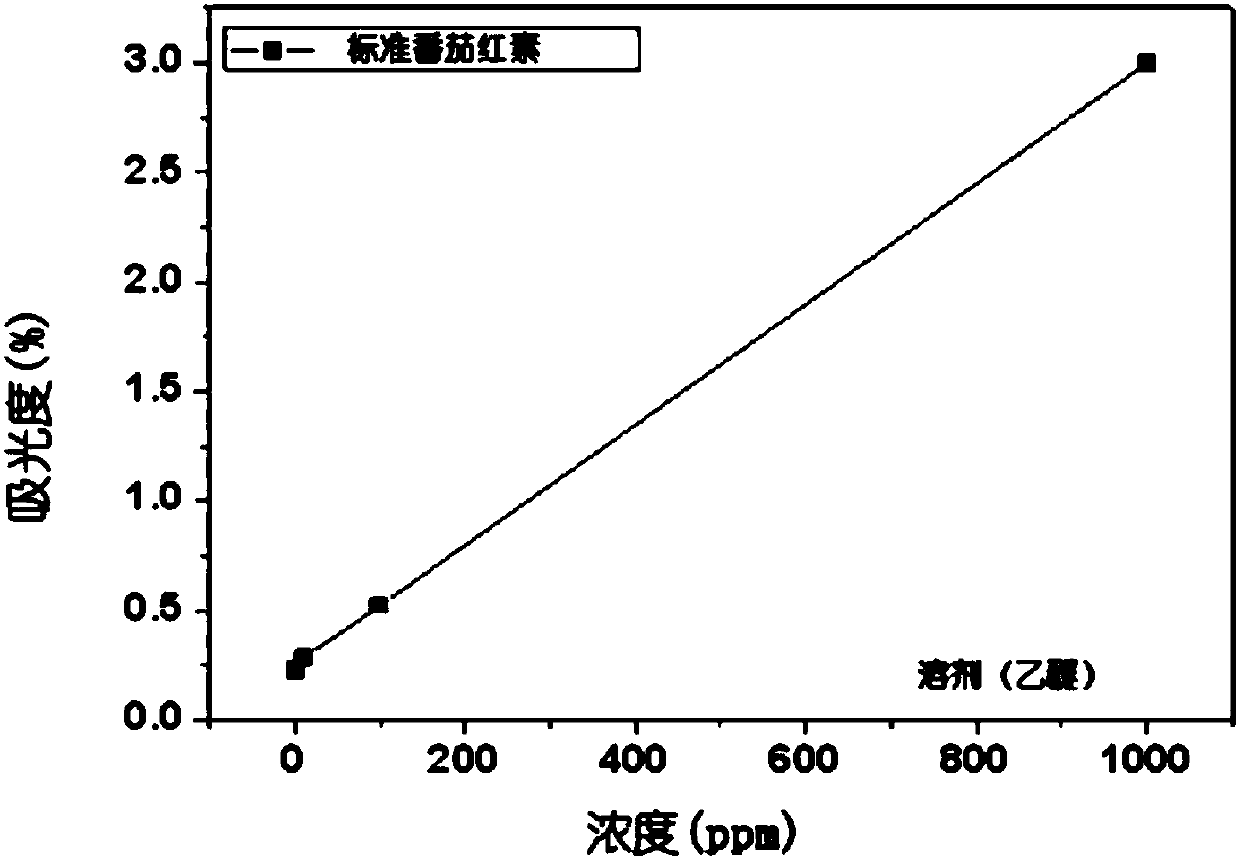

[0071] In terms of the absorbance measured according to the content of standard lycopene (Sigma, Co, USA) figure 2 The standard curve of lycopene was used as a benchmark, and the yield of lycopene prepared was calculated and determined by the following calculation formula.

[0072] 【Calculation formula】

[0073] Y (absorbance) = 0.002742x X (concentration) + 0.258

[0074] Confirming the results of the lycopene yields based on the respective alkali reagents determined according to the calculation formula, it was confirmed that potassium hydroxide had the highest yield, and it was confirmed that potassium hydroxide or sodium carbonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com