Sulfonated poly(arylene ether phosphine oxide) polymer containing phenolphthalein and preparation method of sulfonated poly(arylene ether phosphine oxide) polymer membrane containing phenolphthalein

A technology of sulfonated polyarylether and polymer membrane, which is applied in the field of sulfonated polyarylether phosphine oxide polymer and its membrane preparation, can solve the problems of affecting the dimensional stability of the membrane, loss of mechanical properties, temperature rise, etc., and achieve comprehensive Improve performance, improve overall performance, reduce swelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

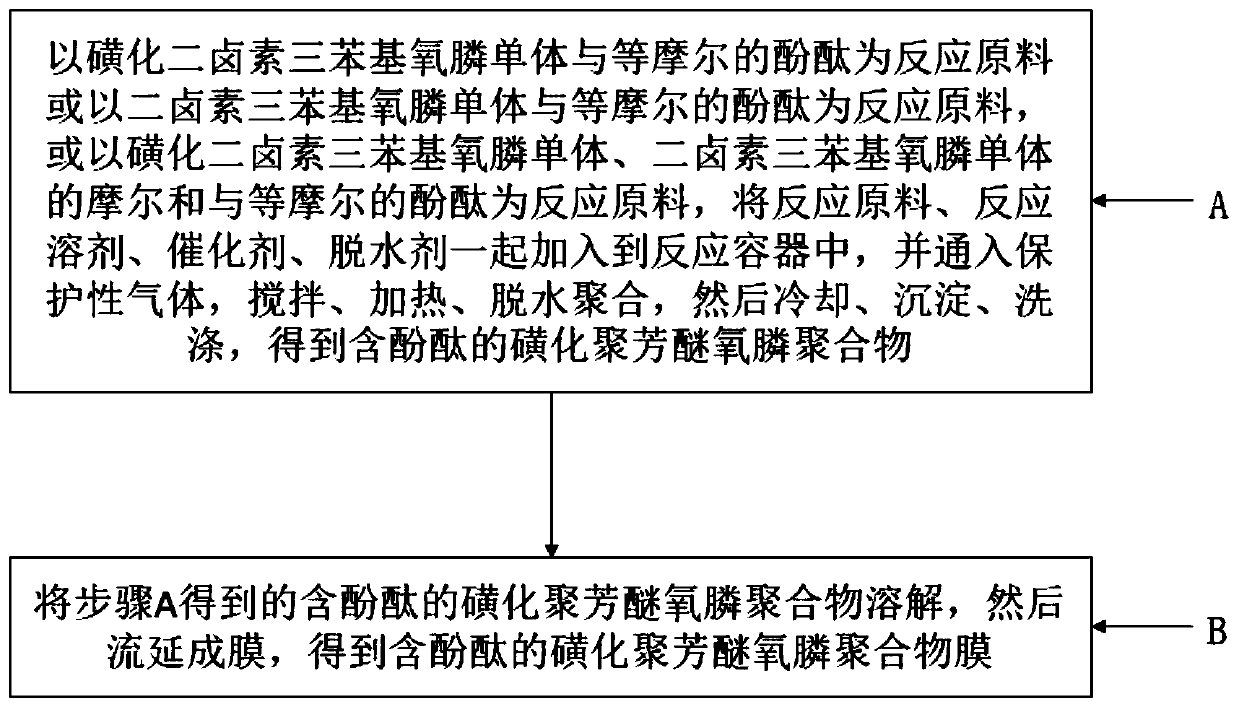

[0040] see figure 1 A method for preparing a phenolphthalein-containing sulfonated polyarylether phosphine oxide polymer film, comprising the following steps:

[0041] A: Use sulfonated dihalogen triphenylphosphine oxide monomer and equimolar phenolphthalein as reaction raw materials, or use dihalogen triphenylphosphine oxide monomer and equimolar phenolphthalein as reaction raw materials, or use sulfonated dihalogen triphenylphosphine oxide monomer as reaction raw material The molar sum of phenylphosphine oxide monomers, dihalogen triphenylphosphine oxide monomers and equimolar phenolphthalein are the reaction raw materials, and the reaction raw materials, reaction solvent, catalyst, and dehydrating agent are added to the reaction vessel together, and passed Protective gas, stirring, heating, dehydration polymerization, then cooling, precipitation, and washing to obtain sulfonated polyarylether phosphine oxide polymers containing phenolphthalein; the heating range is 120 ° C ...

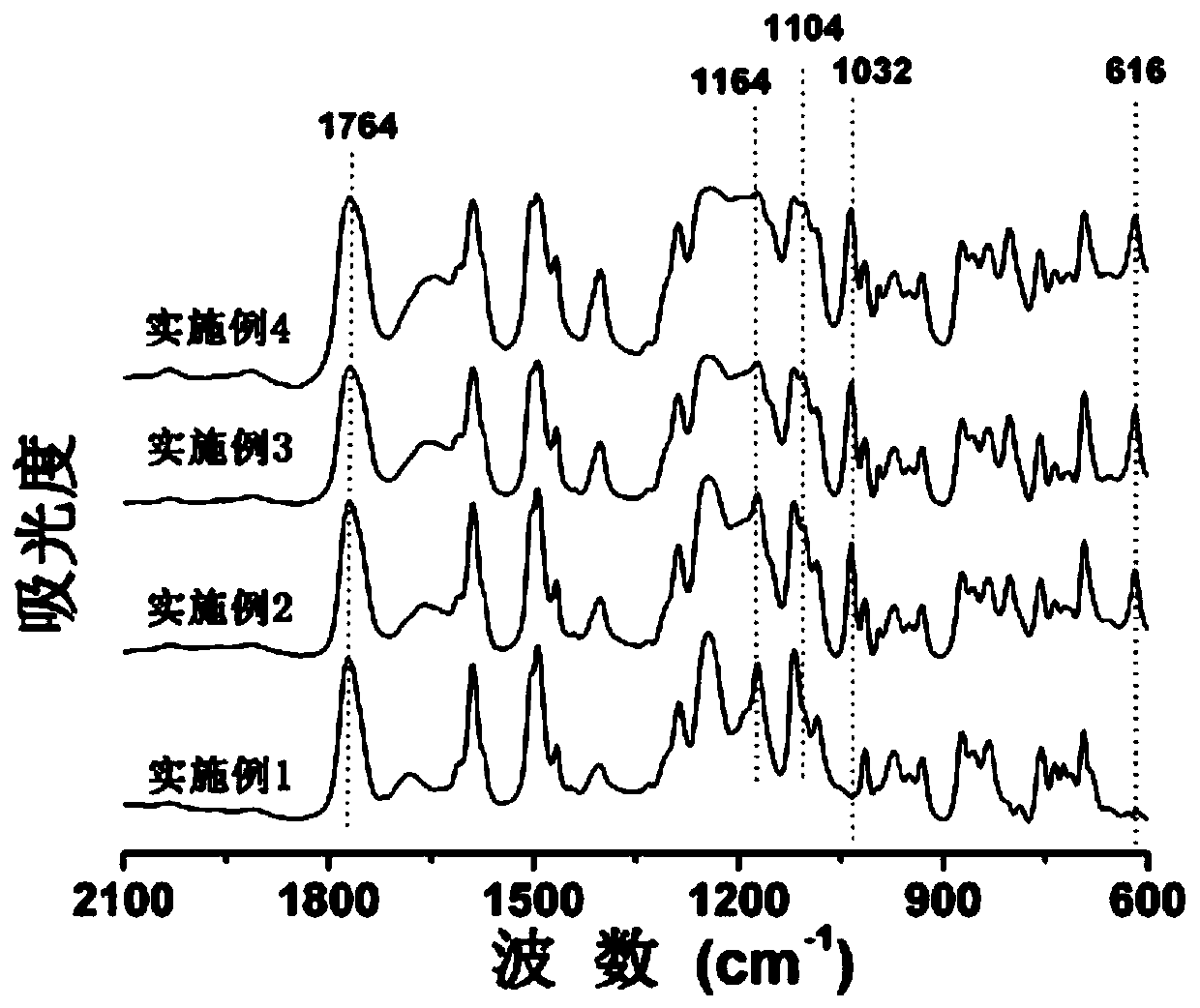

Embodiment 1

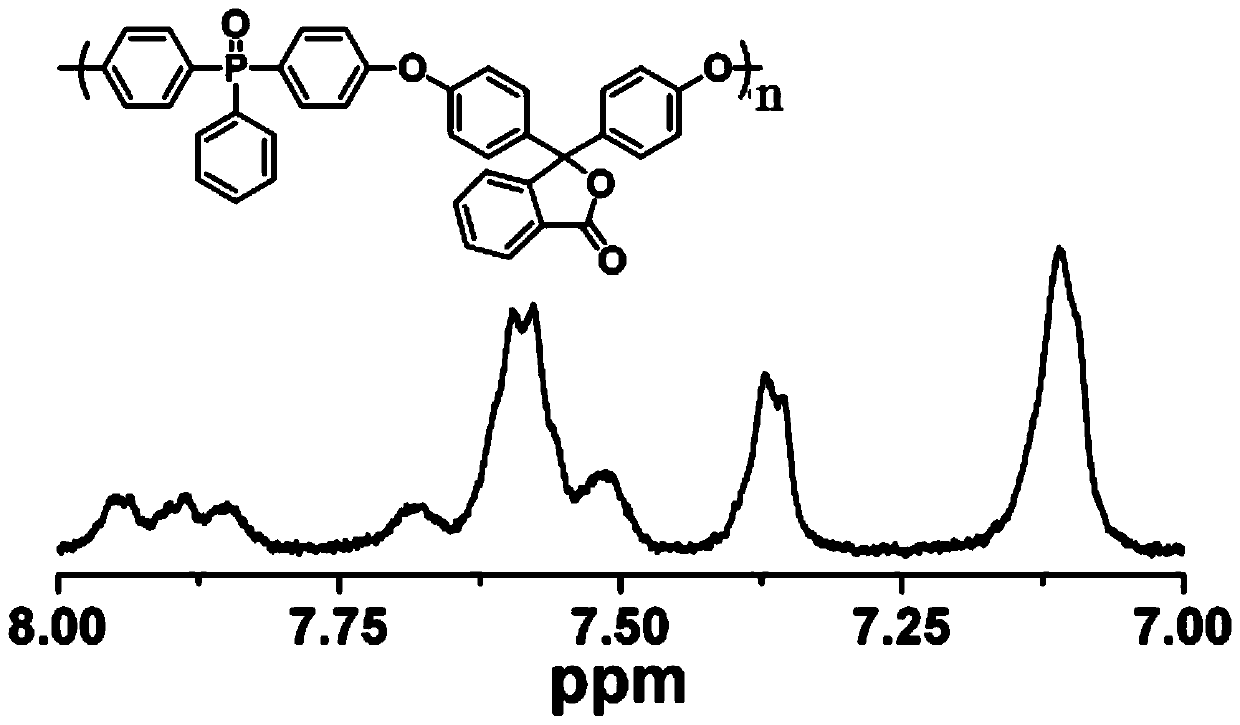

[0070] Add 3.16mmol bis(4-fluorophenyl)phenylphosphine oxide, 3.16mmol phenolphthalein and 3.48mmol K 2 CO 3 , and then add 8 mL of DMAc (N,N-dimethylacetamide) and 8 mL of toluene into the flask, pass through nitrogen protection, and stir at room temperature for 30 min. Raise the temperature to 150°C and allow the reaction system to reflux for 4 hours. During this process, a small amount of water generated by the reaction can be taken away through the water separator along with the reflux of toluene. After the toluene was discharged from the water separator, the reaction was continued at 165° C. for 48 h until the viscosity of the reaction system became very large. The reaction system was naturally cooled to 120°C, and 2 mL of DMAc was added to the three-neck reaction flask to dilute it, and then poured into 300 mL of deionized water, and stirred while pouring to obtain a yellow strip product. Soak the product in hot water to remove K 2 After CO3 inorganic salt, vacuum dry...

Embodiment 2

[0073] Add 2.24mmol bis(4-fluorophenyl)-3'-sulfonate sodium phenylphosphine oxide, 0.56mmol bis(4-fluorobenzene Base) phenylphosphine oxide, 2.80mmol phenolphthalein and 3.08mmol K 2 CO 3 , and then add 8mL DMAc and 8mL toluene into the flask, pass through nitrogen protection, and stir at room temperature for 30min. Raise the temperature to 150°C and allow the reaction system to reflux for 4 hours. During this process, a small amount of water generated by the reaction can be taken away through the water separator along with the reflux of toluene. After the toluene was discharged from the water separator, the reaction was continued at 165° C. for 48 h until the viscosity of the reaction system became very large. The natural temperature of the reaction system was lowered to 120 °C, and 2 mL of DMAc was added to the reaction three-necked flask to dilute it, and then poured into 300 mL of deionized water, and stirred while pouring to obtain a yellow strip product. Soak the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com