Carbon nanofiber and activated carbon composite material and preparation method thereof

A technology of carbon nanofibers and composite materials, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of significant thermal effect and low adsorption efficiency, and achieve high adsorption-desorption efficiency, fast adsorption rate, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

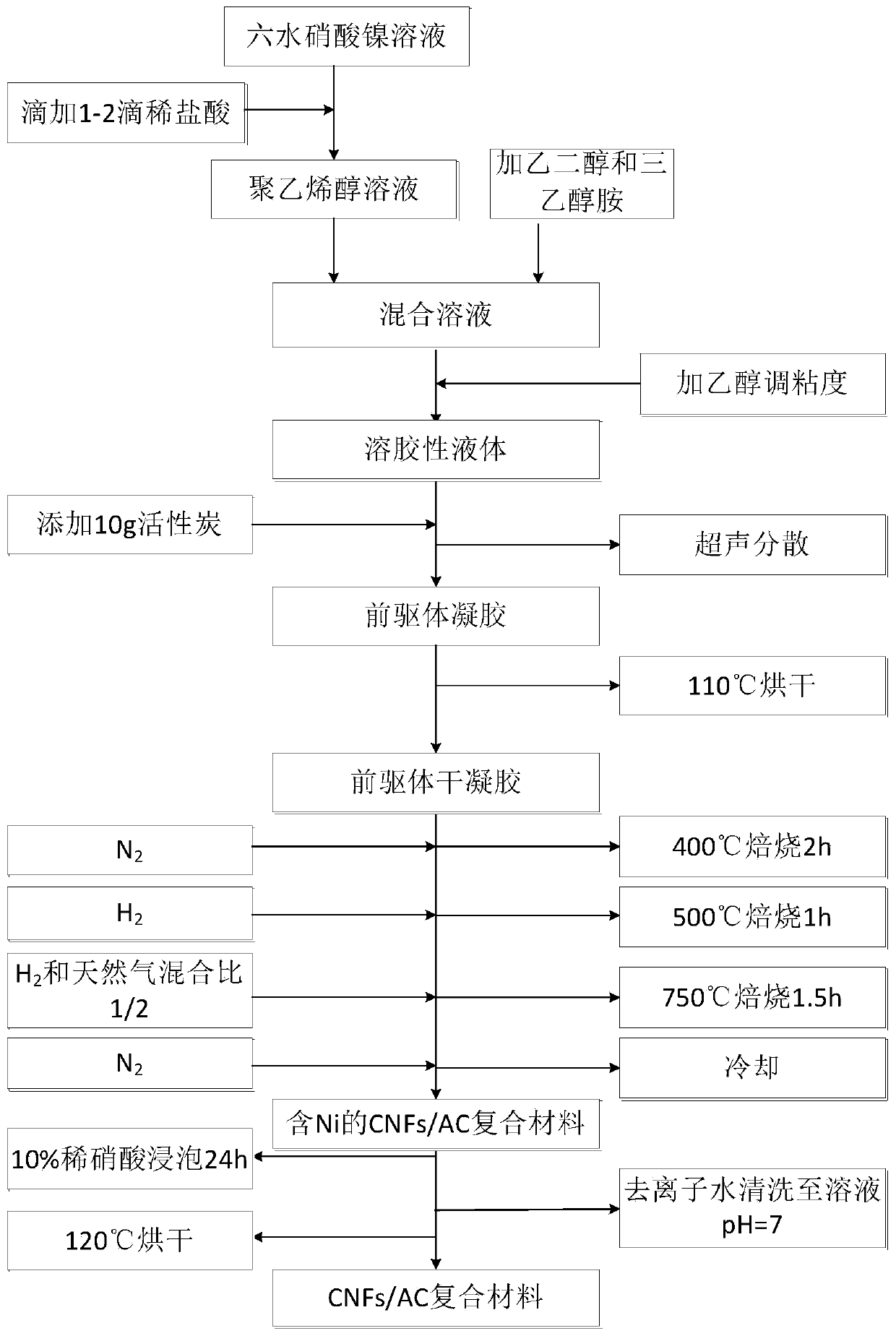

[0028] see figure 1 , the embodiment of the present invention provides a preparation method of carbon nanofiber and activated carbon composite material, comprising:

[0029] Step A, prepare polyvinyl alcohol solution and nickel nitrate hexahydrate solution respectively:

[0030] The preparation of the polyvinyl alcohol solution is as follows: dissolving the polyvinyl alcohol in deionized water, stirring in a constant temperature water bath at 95°C until the polyvinyl alcohol is fully dissolved to prepare a polyvinyl alcohol solution;

[0031] The preparation of nickel nitrate hexahydrate solution is as follows: dissolving nickel nitrate hexahydrate with deionized water, stirring until the nickel nitrate hexahydrate is fully dissolved, and making nickel nitrate hexahydrate solution;

[0032] Step B, add dropwise 0.1 mL of dilute hydrochloric acid with a mass concentration of 10% into the polyvinyl alcohol solution, slowly add the hexahydrate nickel nitrate solution into the po...

Embodiment

[0055] see figure 1 , the present embodiment provides a carbon nanofiber and activated carbon composite material, the preparation method of which comprises the following steps:

[0056] Step A, prepare polyvinyl alcohol solution and nickel nitrate hexahydrate solution respectively;

[0057] Among them, the preparation of the polyvinyl alcohol solution is as follows: dissolve 0.700 g of polyvinyl alcohol in 10 mL of deionized water, stir in a constant temperature water bath at 95 ° C, and wait until it is fully dissolved to make a polyvinyl alcohol solution;

[0058] Preparation of nickel nitrate hexahydrate solution is as follows: dissolve 1.800g nickel nitrate hexahydrate with 10mL deionized water, stir until fully dissolved, and make nickel nitrate hexahydrate solution;

[0059] Step B, first drop 0.1mL (generally 1 to 2 drops) of dilute hydrochloric acid with a mass concentration of 10% into the polyvinyl alcohol solution to prevent precipitation from being hydrolyzed too ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com