Preparation method of fullerene nano-coating gas chromatographic column

A gas chromatographic column and nano-coating technology, applied in the field of chromatographic columns, can solve problems such as easy loss, slow diffusion of samples in the chromatographic column, and performance degradation of the chromatographic column, and achieve the effect of thin solid phase and excellent space selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

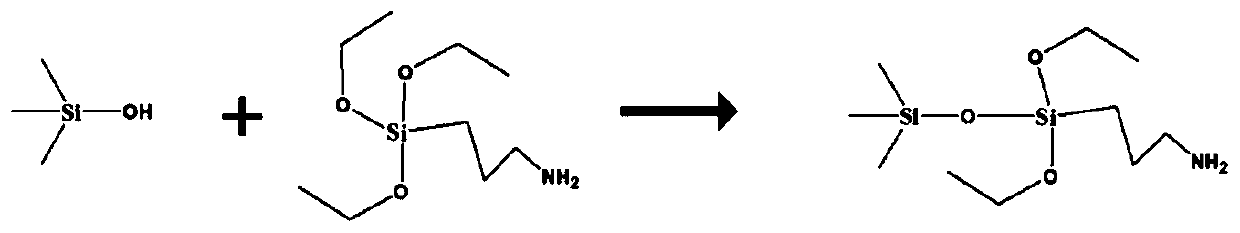

[0028] 1) Activate the fused silica capillary; transport the capillary into the tube with 1.2 mol / L sodium hydroxide, distilled water, 1% hydrofluoric acid by mass fraction, and distilled water in sequence, and activate for 45 minutes each.

[0029] 2) Amination treatment: A xylene solution containing 3% by mass fraction of γ-chloropropyltrimethoxysilane was passed through the capillary tube, reacted at 90°C for 4 hours; washed three times with methanol.

[0030] 3) Preparation of fullerene p-benzoate: 1 part of fullerene and 3 parts of p-azidobenzoic acid were dissolved with 40 parts of toluene, the reaction temperature was 180 C, and the reaction time was 6 hours;

[0031] 4) Bonding fullerenes to a capillary column: Pass a xylene solution containing 5% fullerene terephthalate into the capillary at a reaction temperature of 180°C for 3 hours; wash with toluene three times;

[0032] Analysis and characterization: analyzed by infrared spectroscopic tablet method, the extra 534...

Embodiment 2

[0035] 1) Amination treatment: Pass a xylene solution containing 5% γ-chloropropyltrimethoxysilane into the capillary, react at 75°C for 4 hours; wash with methanol three times.

[0036] 2) Preparation of fullerene p-benzoate: 1 part of fullerene and 3 parts of p-azidobenzoic acid were dissolved in 26 parts of toluene, the reaction temperature was 210C, and the reaction time was 6 hours;

[0037] 3) Bonding fullerenes to the capillary column: passing through the capillary a xylene solution containing 5.5% fullerene terephthalate by mass fraction, at a reaction temperature of 180°C, and reacting for 4 hours; washing with toluene three times;

[0038] Other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com