Fluorapatite purification method and method for preparing fluorohydroxyapatite bioceramic thereof

A technology of fluorohydroxyapatite and fluoroapatite, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of complex operation process, difficult control, high production cost, etc., and achieve the improvement of purity and production The effect of low cost and avoiding high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

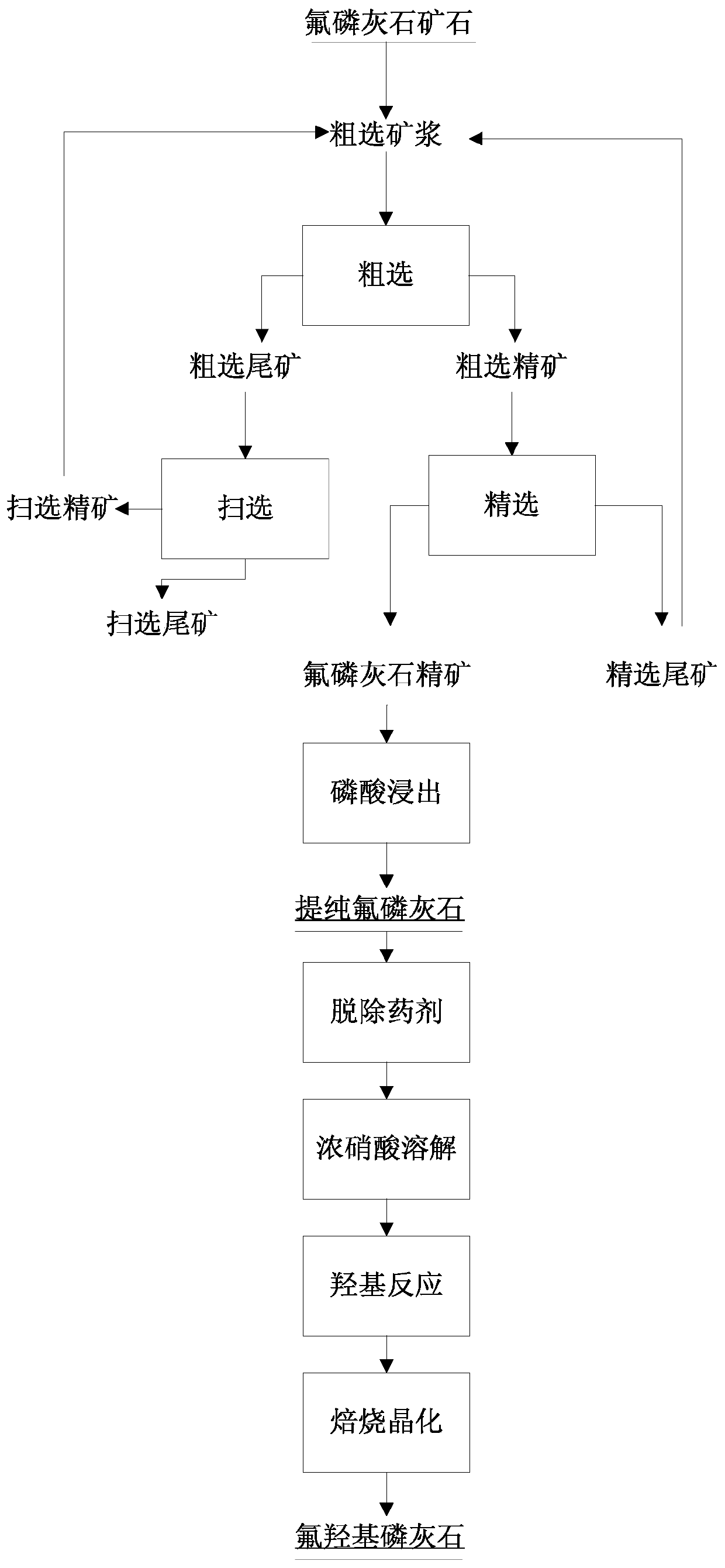

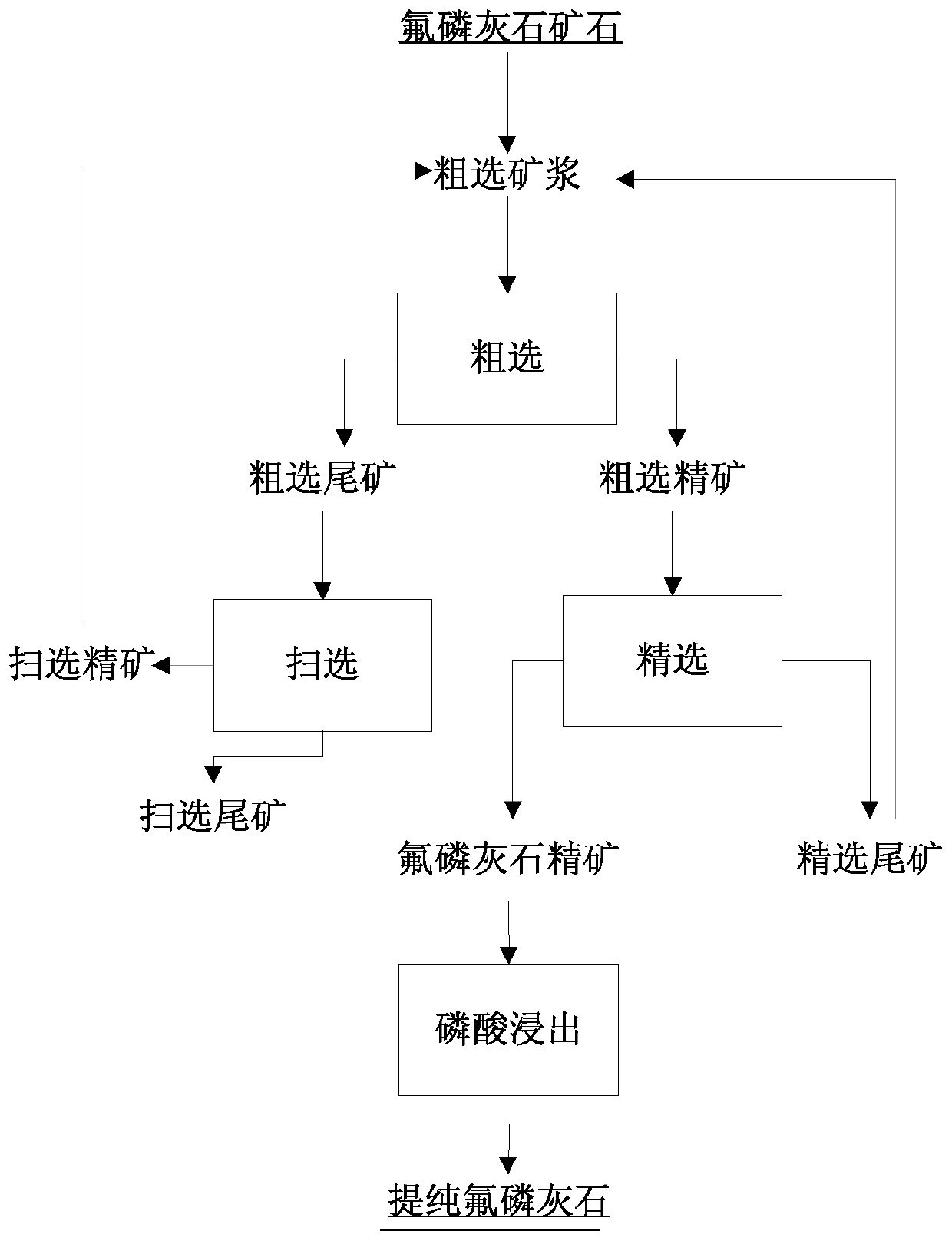

[0077] A method for preparing fluorohydroxyapatite bioceramics from fluoroapatite, the process flow chart is shown in figure 1 , including the following steps:

[0078] Step 1: Flotation Purification

[0079] (1) Fluorapatite ore roughing

[0080] The fluoroapatite ore is wet-milled with a ceramic ball mill, and the product with a particle size of less than 0.074mm accounts for about 80% of the total material weight to obtain fluoroapatite ore powder. The concentration is 75%;

[0081] Transfer the ground fluoroapatite ore powder to the flotation equipment and add water to adjust the slurry to obtain a rougher slurry with a mass concentration of 25%; wherein, the stirring speed is 2200rpm;

[0082] Add the pH adjuster NaOH to the rough dressing pulp to adjust the pH value of the pulp to 9, and stir for 3 minutes, then add the inhibitor sodium carbonate and stir for 3 minutes, the amount of sodium carbonate added is 3000g / t, then add the inhibitor sodium silicate and stir ...

Embodiment 2

[0100] The fluorapatite ore used in this embodiment is the same as that in Embodiment 1.

[0101] A method for preparing fluorohydroxyapatite bioceramics from fluoroapatite, the process flow chart is shown in figure 1 , including the following steps:

[0102] Step 1: Flotation Purification

[0103] (1) Fluorapatite ore roughing

[0104] The fluoroapatite ore is wet-milled with a ceramic ball mill until the particle size of less than 0.074mm accounts for about 77% of the total material weight, and the fluoroapatite ore powder is obtained. Among them, in the wet ball milling, the grinding quality The concentration is 75%;

[0105] Transfer the ground fluoroapatite ore powder to a flotation device and add water to adjust the slurry to obtain a rougher slurry with a mass concentration of 20%; wherein, the stirring speed is 2000rpm;

[0106] Add the pH adjuster NaOH to the rough dressing pulp to adjust the pH value of the pulp to 8, and stir for 3 minutes, then add the inhibito...

Embodiment 3

[0124] The fluorapatite ore used in this embodiment is the same as that in Embodiment 1.

[0125] A method for preparing fluorohydroxyapatite bioceramics from fluoroapatite, the process flow chart is shown in figure 1 , including the following steps:

[0126] Step 1: Flotation Purification

[0127] (1) Fluorapatite ore roughing

[0128] The fluoroapatite ore is wet-milled with a ceramic ball mill until the particle size of less than 0.074mm accounts for about 77% of the total material weight, and the fluoroapatite ore powder is obtained. Among them, in the wet ball milling, the grinding quality The concentration is 75%;

[0129] Transfer the ground fluoroapatite ore powder to the flotation equipment and add water to adjust the slurry to obtain a rougher slurry with a mass concentration of 20%; wherein, the stirring speed is 1800rpm;

[0130] Add the pH adjuster NaOH to the rough dressing pulp to adjust the pH value of the pulp to 7, and stir for 3 minutes, then add the inh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com