Aqueous resin modified asphalt pavement maintenance material and preparation method thereof

A technology of modified asphalt and water-based resin is applied in the fields of asphalt pavement maintenance materials, asphalt pavement fog seals and anti-slip thin layer overlay materials, which can solve the problems of poor driving comfort, insufficient skid resistance, and water damage resistance. To achieve the effect of good driving comfort, improved water damage resistance and anti-skid ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

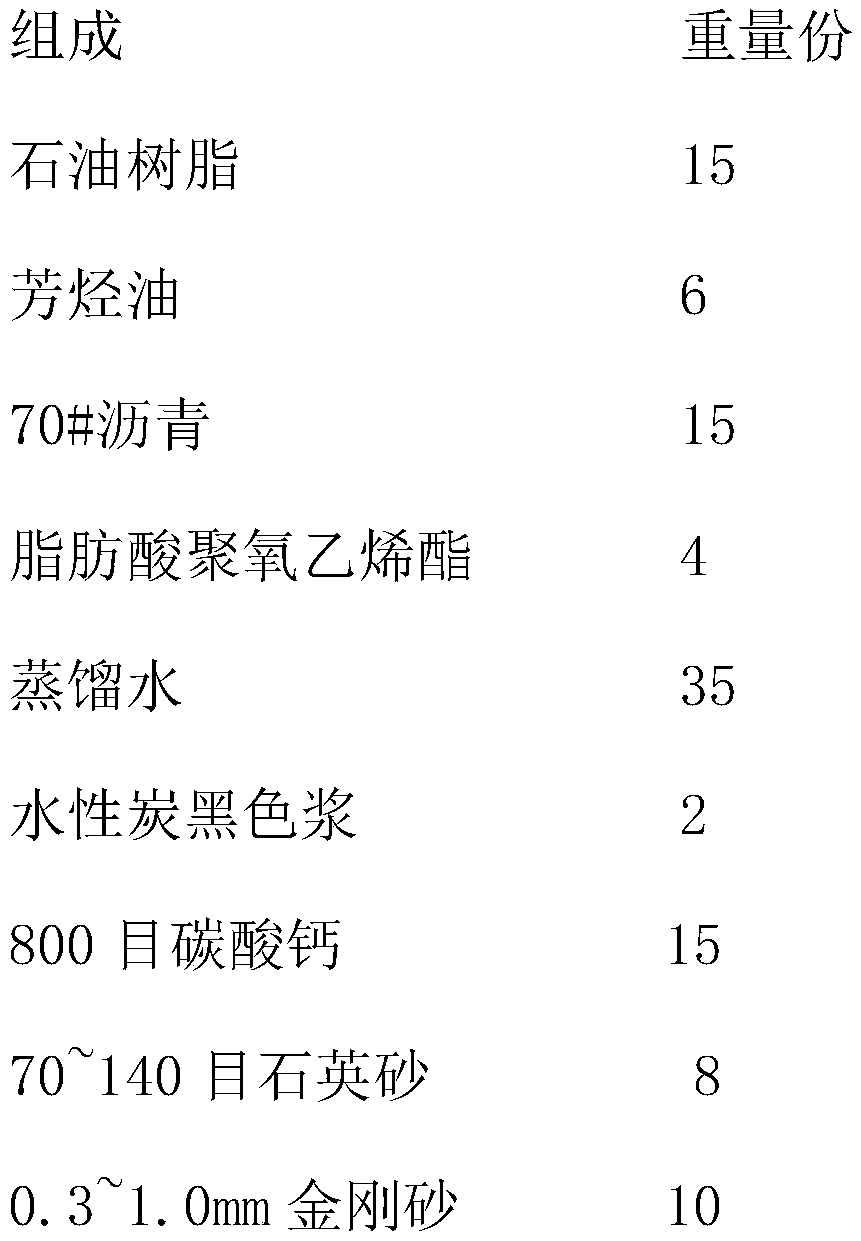

[0026] A water-based resin modified asphalt pavement maintenance material, comprising the following components by weight:

[0027]

[0028] (1) Put petroleum resin, 70# asphalt, aromatic hydrocarbon oil and fatty acid polyoxyethylene ester into a container equipped with a high-speed shear disperser, heating mantle, and condensation recovery device, heat to 135°C, and stir slowly at a low speed to make each group Divide and mix well.

[0029] (2) Cool down to 90°C, increase the speed of the shear disperser, and slowly add measured distilled water. Continue high-speed shear dispersion for 60 minutes after adding water to complete emulsification.

[0030] (3) Add water-based carbon black slurry, and disperse for 30 minutes under high-speed shearing.

[0031] (4) Add 800 mesh calcium carbonate, stir and disperse evenly, and the temperature drops to normal temperature.

[0032] (5) Add metered 70-140 mesh quartz sand and corundum with a particle size of 0.3-1.0 mm and stir ev...

Embodiment 2

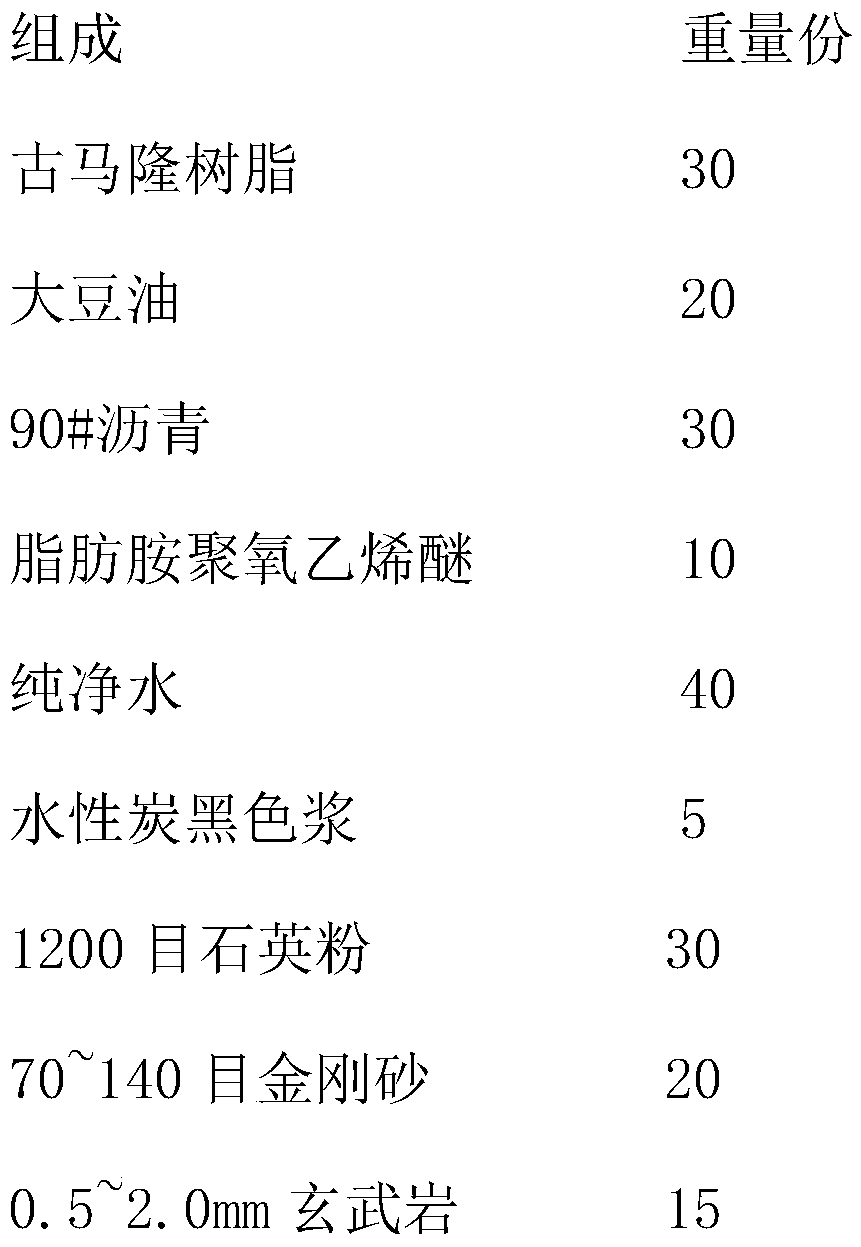

[0034] A water-based resin modified asphalt pavement maintenance material, comprising the following components by weight:

[0035]

[0036] (1) Add coumarone resin, 90# asphalt, soybean oil and fatty amine polyoxyethylene ether into a container equipped with a high-speed shear disperser, heating mantle, and condensation recovery device, heat to 130°C, and stir slowly at a low speed. Mix the ingredients well.

[0037] (2) Cool down to 85°C, increase the speed of the shear disperser, and slowly add measured purified water. Continue high-speed shear dispersion for 120 minutes after adding water to complete emulsification.

[0038] (3) Add water-based carbon black slurry, and disperse at high speed for 20 minutes.

[0039] (4) Add 1200 mesh quartz powder, stir to disperse evenly, and lower the temperature to normal temperature.

[0040] (5) Add metered 70-140 mesh corundum and basalt with a particle size of 0.5-2.0 mm and stir evenly to obtain the water-based resin-modified ...

Embodiment 3

[0042] A water-based resin modified asphalt pavement maintenance material, comprising the following components by weight:

[0043]

[0044]

[0045] (1) Add rosin resin, 110# asphalt, turpentine and fatty alcohol polyoxyethylene ether into a container equipped with a high-speed shear disperser, a heating mantle, and a condensation recovery device, heat to 125°C, and stir slowly at a low speed to make each group Divide and mix well.

[0046] (2) Cool down to 80°C, increase the speed of the shear disperser, and slowly add measured distilled water. Continue high-speed shear dispersion for 30 minutes after adding water to complete emulsification.

[0047] (3) Add water-based carbon black slurry, and disperse at high speed for 10 minutes.

[0048] (4) Add 1500 mesh calcined kaolin, stir and disperse evenly, and lower the temperature to normal temperature.

[0049] (5) Add metered 70-140 mesh corundum and basalt with a particle size of 0.5-1.0 mm and stir evenly to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com