Side slope protection and vegetation restoration method

A technology for vegetation restoration and slope protection, applied in botany equipment and methods, soil preparation methods, planting substrates, etc., can solve the problems of slow growth of plant roots, inability to integrate, and inability to maintain slope protection for a long time, and achieve plant The effect of high survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of slope protection and vegetation restoration method

[0036] A method for slope protection and vegetation restoration, using a double-layer fiber spraying structure:

[0037] The first layer, the bottom layer, improves the nutrient layer for the soil and can quickly ripen the raw soil.

[0038] The second layer, the surface layer, is an anti-scour plant protection layer, which quickly provides a strong anti-scour cover while providing growth space and nutrients for plant growth.

[0039] Different proportions of plant seeds can be mixed in the two-layer structure.

[0040] The underlying structure can be directly applied to barren soil slopes or mountains for rapid soil improvement.

Embodiment 2

[0041] Embodiment 2 A kind of slope protection and vegetation restoration method

[0042] A slope protection structure, including a two-layer structure, respectively a bottom layer and a surface layer;

[0043] Seeding substrates for bottom and top coats:

[0044] (1) The bottom layer is a heat-treated wood fiber layer, the mass percentage of the heat-treated wood fiber is 89%, and the content of other components is 11%.

[0045] The raw materials of the heat-treated wood fiber layer include the following components in parts by weight: 89 parts of heat-treated wood fiber, 3 parts of seaweed extract, 2 parts of composite bacterial agent, and 6 parts of humic acid;

[0046] The heat-treated wood fiber: short porous fiber with a length of 1-2cm and a diameter of 0.1-1mm; the fiber content of 2cm in length is ≥50%; the preparation method of the heat-treated wood fiber is made of bark, wood chips, etc. It is formed by pyrolysis under high temperature and high pressure conditions;...

Embodiment 3

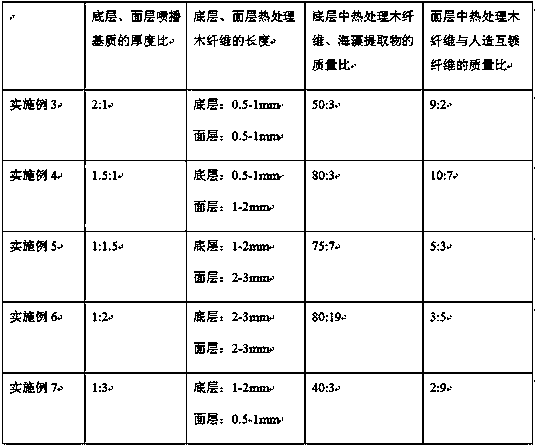

[0073] Embodiment 3 A kind of multi-factor analysis experiment of slope protection and vegetation restoration method

[0074] Identical with the method of embodiment 2, only change following factor, carry out embodiment 3-7; Specifically as follows:

[0075]

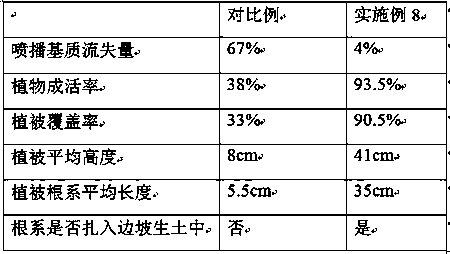

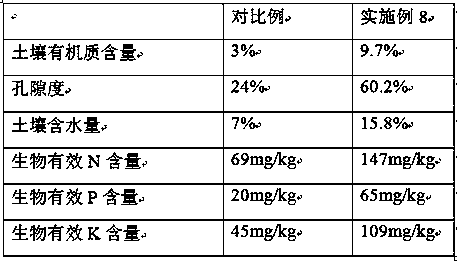

[0076] After testing, the methods of Examples 2-7 were respectively implemented on gravel soil slopes with a slope of H / L 2.5:1. After 2 hours, the simulated 127mm / h rainfall was evenly spread to the slope, and a total of rainfall 8h; Detect the loss rate of the sprayed substrate, see the table below for details:

[0077]

[0078] As can be seen from the above table, embodiment 5 is a preferred embodiment, and the thickness ratio of bottom layer and surface layer spraying matrix is preferably 1:1.5, and the length of bottom heat-treated wood fiber is 1-2cm, and the length of surface layer heat-treated wood fiber is 2-2 cm. 3cm, the mass ratio of heat-treated wood fiber and seaweed extract in the bottom layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com