Preparation method of carbon nanotube metal symbiotic material

A technology of carbon nanotubes and metals, which is applied in the field of preparation of carbon nanotube metal symbiotic materials, can solve problems such as difficult control, uneven metal particle size, difficult control of metal loading, etc., to achieve uniformity and good catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

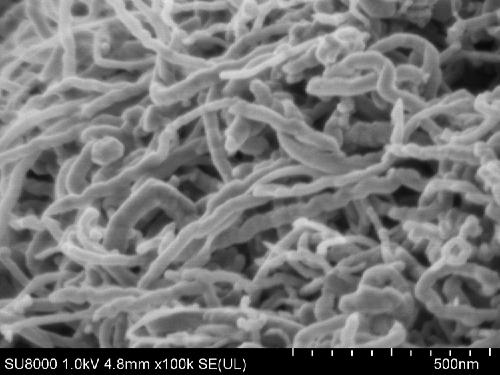

Image

Examples

Embodiment 1

[0025] A preparation method of carbon nanotube cobalt symbiotic material includes the following steps:

[0026] (1) Add 1.40 g Co(NO 3 ) 2 ·6H 2 O and 1.00g Al passed through a 150 mesh sieve 2 O 3 The carrier was mixed, added with deionized water, immersed in ultrasonic treatment for 4h, filtered, and the obtained filter residue was washed 3 times with deionized water, then dried, and calcined at 500°C for 4h to obtain a cobalt-based catalyst; in the cobalt-based catalyst, The content of cobalt is based on the mass of cobalt trioxide, accounting for 28.57% of the mass of the cobalt-based catalyst;

[0027] (2) Put the cobalt-based catalyst in the reactor, and then pass in the inert gas nitrogen to replace the air and then pass in the reducing gas hydrogen for 50 minutes. The hydrogen space velocity is 10000mL / g / h, heated to 600℃, and the reduction is stopped. Then pass the carbon source methane, the space velocity is controlled at 20000 mL / g / h, the reaction is 2h, the inert gas ni...

Embodiment 2

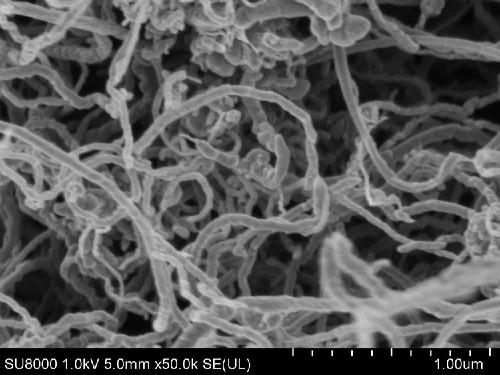

[0029] A preparation method of carbon nanotube iron symbiotic material, including the following steps:

[0030] (1) Add 3.54 g Fe(NO 3 ) 3 ·9H 2 O and 1.00g SiO passed through 200 mesh sieve 2 The carrier was mixed, added with deionized water, immersed in ultrasonic treatment for 3h, filtered, and the obtained filter residue was washed with deionized water 3 times, then dried, and calcined at 450°C for 5h to obtain an iron-based catalyst; in the iron-based catalyst, The iron content is based on the mass of ferric oxide, accounting for 41.18% of the mass of the iron-based catalyst;

[0031] (2) Put the iron-based catalyst in the reactor, and then pass in the inert gas argon to replace the air, and then pass in the reducing gas methane for 10 minutes. The reducing gas methane has a space velocity of 30,000 mL / g / h, and then heat to 700°C , Continue to pass in methane, control the space velocity at 15000 mL / g / h, react for 4 hours, pass in the inert gas argon again, and drop to room tem...

Embodiment 3

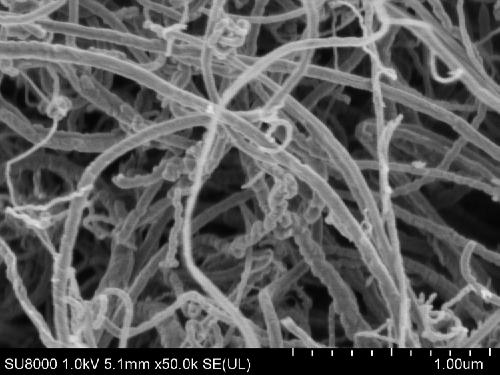

[0033] A preparation method of carbon nanotube nickel symbiotic material, including the following steps:

[0034] (1) Add 8.95g Ni(NO 3 ) 2 ·6H 2 O and 1.50g of ZSM-5 carrier passed through a 100-mesh sieve were mixed, added with deionized water, immersed in ultrasonic treatment for 2h, filtered, and the obtained filter residue was washed with deionized water for 3 times, then dried and calcined at 480℃ for 4h. Obtain a nickel-based catalyst; in the nickel-based catalyst, the content of nickel is based on the mass of nickel oxide, accounting for 60.52% of the mass of the nickel-based catalyst;

[0035] (2) Put the nickel-based catalyst in the reactor, and pass the inert gas helium to replace the air and then pass the reducing gas methane for 20 minutes, the reducing gas methane space velocity is 15000mL / g / h, and then heating to 750℃ , Stop feeding the reducing gas methane, and then feed the carbon source ethane, the space velocity is controlled at 15000 mL / g / h, the reaction is 1.5h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com