Method for realizing evolution of various nano morphologies of zinc oxide

A technology of zinc oxide nanometer and nanometer morphology, applied in zinc oxide/zinc hydroxide, nanotechnology, nanotechnology and other directions, can solve problems such as reducing process steps and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

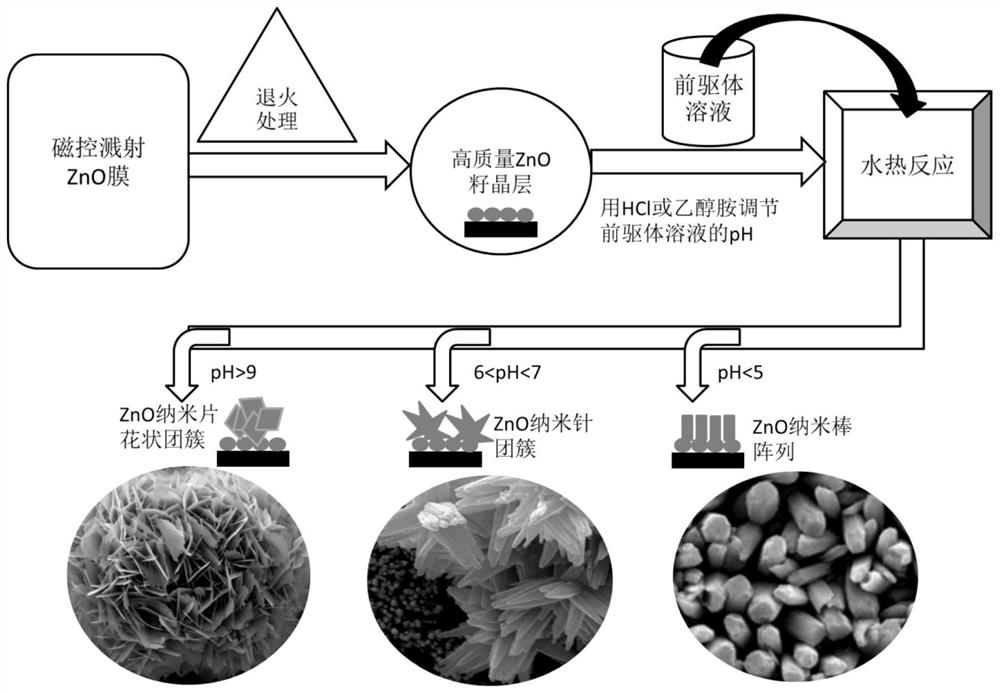

[0049] A method for realizing the evolution of zinc oxide (ZnO) multiple nano-morphologies, comprising the following steps:

[0050] (1) Use AC magnetron sputtering system to prepare nano-zinc oxide seed crystal layer on ITO glass substrate, use argon gas with a purity of 99.99% as sputtering gas, and its working pressure is 3×10 -3 Pa, the substrate temperature is room temperature (25° C.), the flow rate of the sputtering gas is 20 sccm, the distance between the RF source and the substrate is 4 cm, and the sputtering power is 120 W for 30 minutes. Before formally sputtering the substrate, a high-purity zinc oxide target with a diameter of 110 mm and a thickness of 6 mm (the purity of the target is 99.99%) is pre-sputtered for 5 minutes to remove impurities and reduce the impact of impurity particles on zinc oxide in the later stage. Crystal defects caused by nanorod growth.

[0051] (2) Annealing the seed layer in an air atmosphere at a temperature of 550° C. for 2 hours in ...

Embodiment 2

[0057] A method for realizing the evolution of various nano-morphologies of zinc oxide, comprising the following steps:

[0058] (1) The nano-zinc oxide seed layer was prepared on the soda glass substrate using an AC magnetron sputtering system. Its working air pressure is 5x10 -3 Pa, other conditions and processes are exactly the same as step (1) in Example 1, and will not be repeated here.

[0059] (2) Annealing the seed layer in an air atmosphere at a temperature of 500° C. for 2 hours in a horse-boiling furnace to better control the growth of zinc oxide crystals.

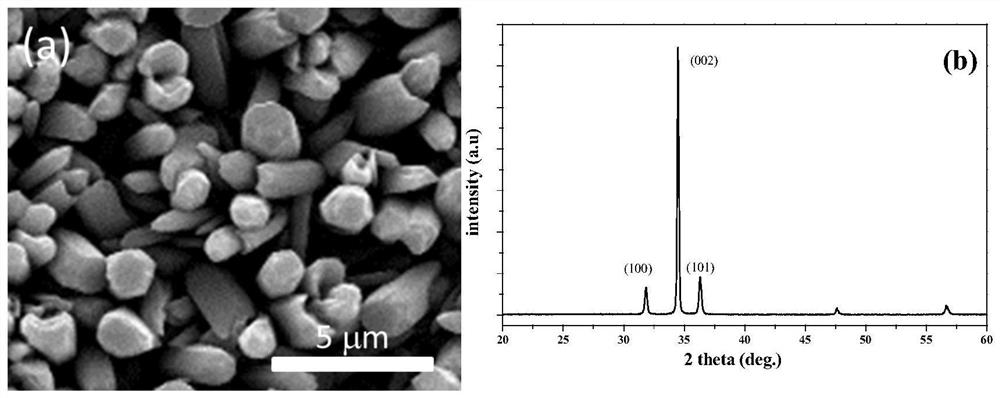

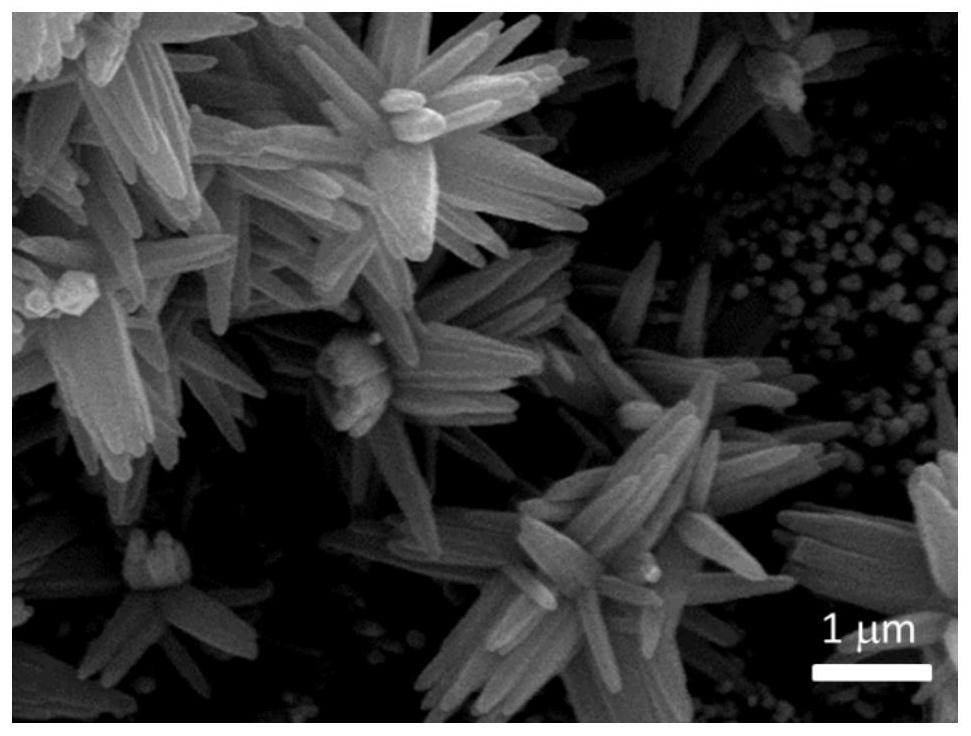

[0060] (3) Using a hydrothermal method to grow zinc oxide nanostructures on the prepared seed layer. The precursor solution uses hexamethylenetetramine (C 6 h 12 N 4 , with a purity of 99.0%) and zinc nitrate (Zn(NO 3 ) 2 , with a purity of 99.0%), and then adjust the pH values with ethanolamine and hydrochloric acid. Finally, the prepared solutions were poured into polytetrafluoroethylene autoclaves, ...

Embodiment 3

[0065] A method for realizing the evolution of zinc oxide (ZnO) multiple nano-morphologies, comprising the following steps:

[0066] (1) A nano-zinc oxide seed layer was prepared on a quartz substrate using an AC magnetron sputtering system. Its working air pressure is 8x10 -3 Pa, other conditions and processes are exactly the same as step (1) in Example 1, and will not be repeated here.

[0067] (2) Annealing the seed crystal layer in an air atmosphere at a temperature of 600° C. for 2 hours in a horse-boiling furnace to better control the growth of zinc oxide crystals.

[0068] (3) Using a hydrothermal method to grow zinc oxide nanostructures on the prepared seed layer. The precursor solution uses hexamethylenetetramine (C 6 h 12 N 4 , with a purity of 99.0%) and zinc nitrate (Zn(NO 3 )2 , with a purity of 99.0%), and then adjust the pH values with ethanolamine and hydrochloric acid. Finally, the prepared solutions were poured into polytetrafluoroethylene autoclaves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com