Anti-haze gypsum wall material for prefabricated building and preparation method of anti-haze gypsum wall material

A wall material and technology for construction, applied in the field of anti-smog gypsum wall material and preparation for prefabricated buildings, can solve problems affecting development and application, construction difficulties, etc., and achieve high catalytic efficiency and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

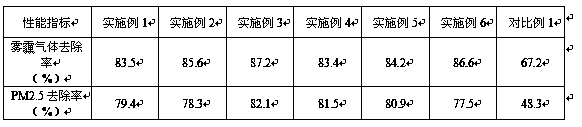

Examples

Embodiment 1

[0027] (1) First add bismuth oxide photocatalyst and foaming agent into deionized water, stir and disperse evenly, then add binder, carry out ultrasonic-assisted dispersion to obtain a stable solution, and then immerse porous glass microspheres in the solution for 1 hour to obtain Porous glass microsphere glue;

[0028] The foaming agent is ammonium carbonate; the binder is an epoxy resin binder; each raw material is calculated according to mass percentage, 6% of bismuth oxide photocatalyst, 5% of foaming agent, 44% of deionized water, and 14% of binder , Porous glass microspheres 31%;

[0029] (2) First mix β-phosphogypsum hemihydrate, cement, fly ash, foaming agent, polycarboxylate water reducer, salt water repellent, and waste plastic fibers to obtain powdery mixed raw materials, and then gradually add The emulsion compounded by water, crystal modifier, polyvinyl alcohol and hydrogen-containing silicone oil is stirred into a uniform slurry, and then the slurry is injected ...

Embodiment 2

[0033] (1) First add bismuth oxide photocatalyst and foaming agent into deionized water, stir and disperse evenly, then add binder, carry out ultrasonic-assisted dispersion to obtain a stable solution, and then immerse porous glass microspheres in the solution for 2 hours to obtain Porous glass microsphere glue;

[0034] The foaming agent is ammonium bicarbonate; the binding agent is a polyurethane binding agent; each raw material is calculated according to mass percentage, bismuth oxide photocatalyst 9%, foaming agent 7%, deionized water 34%, binding agent 16%, Porous glass microspheres 34%;

[0035] (2) First mix β-phosphogypsum hemihydrate, cement, fly ash, foaming agent, polycarboxylate water reducer, salt water repellent, and waste plastic fibers to obtain powdery mixed raw materials, and then gradually add The emulsion compounded by water, crystal modifier, polyvinyl alcohol and hydrogen-containing silicone oil is stirred into a uniform slurry, and then the slurry is in...

Embodiment 3

[0039] (1) First add bismuth oxide photocatalyst and foaming agent into deionized water, stir and disperse evenly, then add binder, carry out ultrasonic-assisted dispersion to obtain a stable solution, and then immerse porous glass microspheres in the solution for 2 hours to obtain Porous glass microsphere glue;

[0040] The foaming agent is sodium carbonate; the binder is an epoxy resin binder; each raw material is calculated according to mass percentage, bismuth oxide photocatalyst 7%, foaming agent 6%, deionized water 42%, binder 14% , Porous glass microspheres 32%;

[0041] (2) First mix β-phosphogypsum hemihydrate, cement, fly ash, foaming agent, polycarboxylate water reducer, salt water repellent, and waste plastic fibers to obtain powdery mixed raw materials, and then gradually add The emulsion compounded by water, crystal modifier, polyvinyl alcohol and hydrogen-containing silicone oil is stirred into a uniform slurry, and then the slurry is injected into the mold and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com