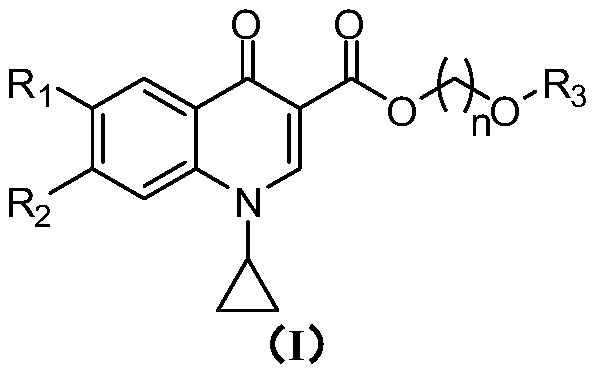

Quinoline carboxylic acid ester compound and preparation method and application thereof

An ester compound, quinoline carboxylic acid technology, applied in the field of agricultural bactericides, can solve the problems of small promotion area, limited resistance and control effect, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

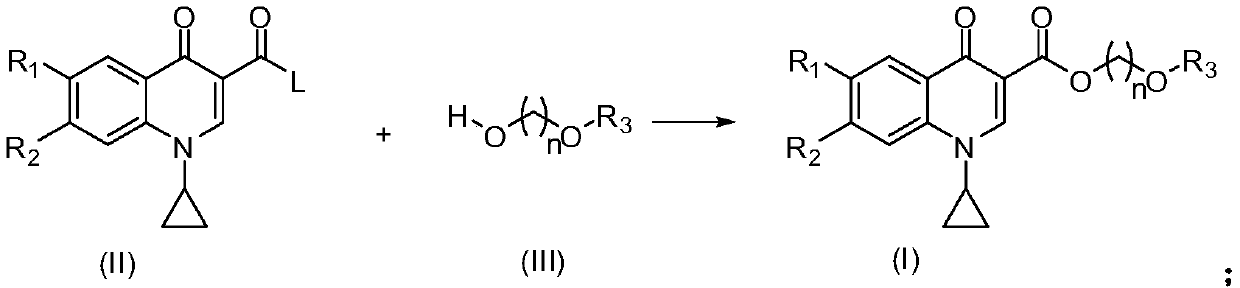

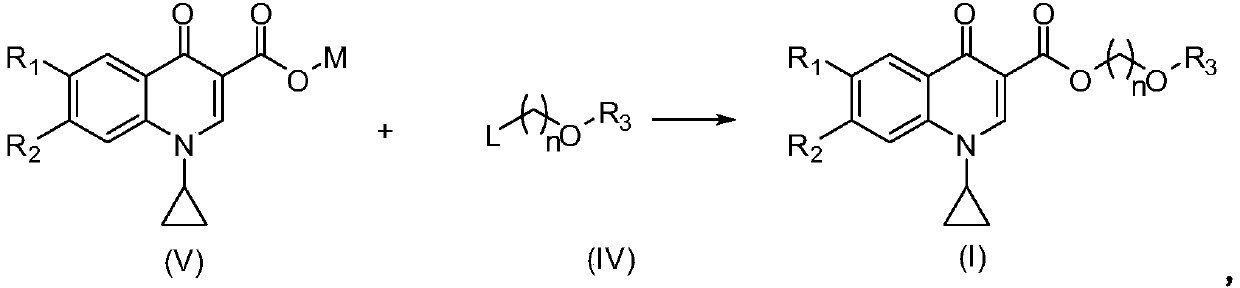

Method used

Image

Examples

Embodiment 1

[0143] Example 1: Methoxymethyl 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylate (compound 1)

[0144]

[0145] The first step reaction: Potassium 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylate

[0146] At room temperature, 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylic acid (12.3g, 0.05mol), 30% aqueous potassium hydroxide solution (12ml) was added to In a three-neck bottle. Heated to 60°C and reacted for 2 hours. Heating was stopped, and the product was dehydrated under reduced pressure to obtain 13.6 g of the product with a yield of 96%.

[0147] The second step reaction: Methoxymethyl 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylate

[0148] At room temperature, potassium 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylate (2.85g, 0.01mol), chloromethyl methyl ether (0.96g, 0.012 mol) were successively dissolved in N,N-dimethylformamide (15ml). Heated to 100°C and reacted for 6 hours. Heati...

Embodiment 2

[0150] Example 2: 2-methoxyethyl 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylate (compound 10)

[0151]

[0152] The first step reaction: 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-oyl chloride

[0153] At room temperature, mix 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylic acid (14.9g, 0.06mol), dichloroethane (90ml) and N,N - Dimethylformamide (0.2g) was added into a three-necked flask, and thionyl chloride (14.6g, 0.12mol) was added dropwise to the above mixture. Heat to reflux for 5 hours. Heating was stopped, and the solvent and residual thionyl chloride were removed under reduced pressure to obtain 14.6 g of the product with a yield of 92%.

[0154] The second step reaction: 2-methoxyethyl 1-cyclopropyl-6-fluoro-4-oxo-1,4-dihydroquinoline-3-carboxylate

[0155] At room temperature, 2-methoxyethanol (0.76g, 0.01mol) and triethylamine (2.02g, 0.02mol) were successively dissolved in dichloromethane (20ml). Cool to 0°C in a cry...

Embodiment 3

[0157] Example 3: 2-methoxyethyl 6-chloro-1-cyclopropyl-4-oxo-1,4-dihydroquinoline-3-carboxylate (compound 45)

[0158]

[0159] The first step reaction: 6-chloro-1-cyclopropyl-4-oxo-1,4-dihydroquinoline-3-acid chloride

[0160] At room temperature, mix 6-chloro-1-cyclopropyl-4-oxo-1,4-dihydroquinoline-3-carboxylic acid (15.8g, 0.06mol), dichloroethane (90ml) and N,N - Dimethylformamide (0.2g) was added into a three-necked flask, and thionyl chloride (14.6g, 0.12mol) was added dropwise to the above mixture. Heat to reflux for 5 hours. Heating was stopped, and the solvent and residual thionyl chloride were removed under reduced pressure to obtain 16.2 g of the product with a yield of 96%.

[0161] The second step reaction: 2-methoxyethyl 6-chloro-1-cyclopropyl-4-oxo-1,4-dihydroquinoline-3-carboxylate

[0162] At room temperature, 2-methoxyethanol (0.76g, 0.01mol) and triethylamine (2.02g, 0.02mol) were successively dissolved in dichloromethane (20ml). Cool to 0°C in a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com