Biosensing chip and preparation method and application thereof

A bio-sensing and chip technology, applied in the field of sensors, achieves strong adsorption efficiency, expands application scenarios, and is easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Another aspect of the present invention provides a method for preparing the biosensor chip, comprising the steps of:

[0037] S01: Coating a layer of base film on one side of the prism;

[0038] S02: depositing a coupling layer on the base film;

[0039] S03: Finally, deposit a transfer layer on the surface of the coupling layer.

[0040] Specifically, in the step S01, a physical vapor deposition method may be used to vapor-deposit a metal thin film.

[0041] Specifically, in the step S02, a coupling layer may be deposited on the gold film by a plasma-enhanced chemical vapor deposition system.

[0042] Specifically, in the step S03, a transfer layer may be deposited on the surface of the coupling layer by chemical vapor deposition.

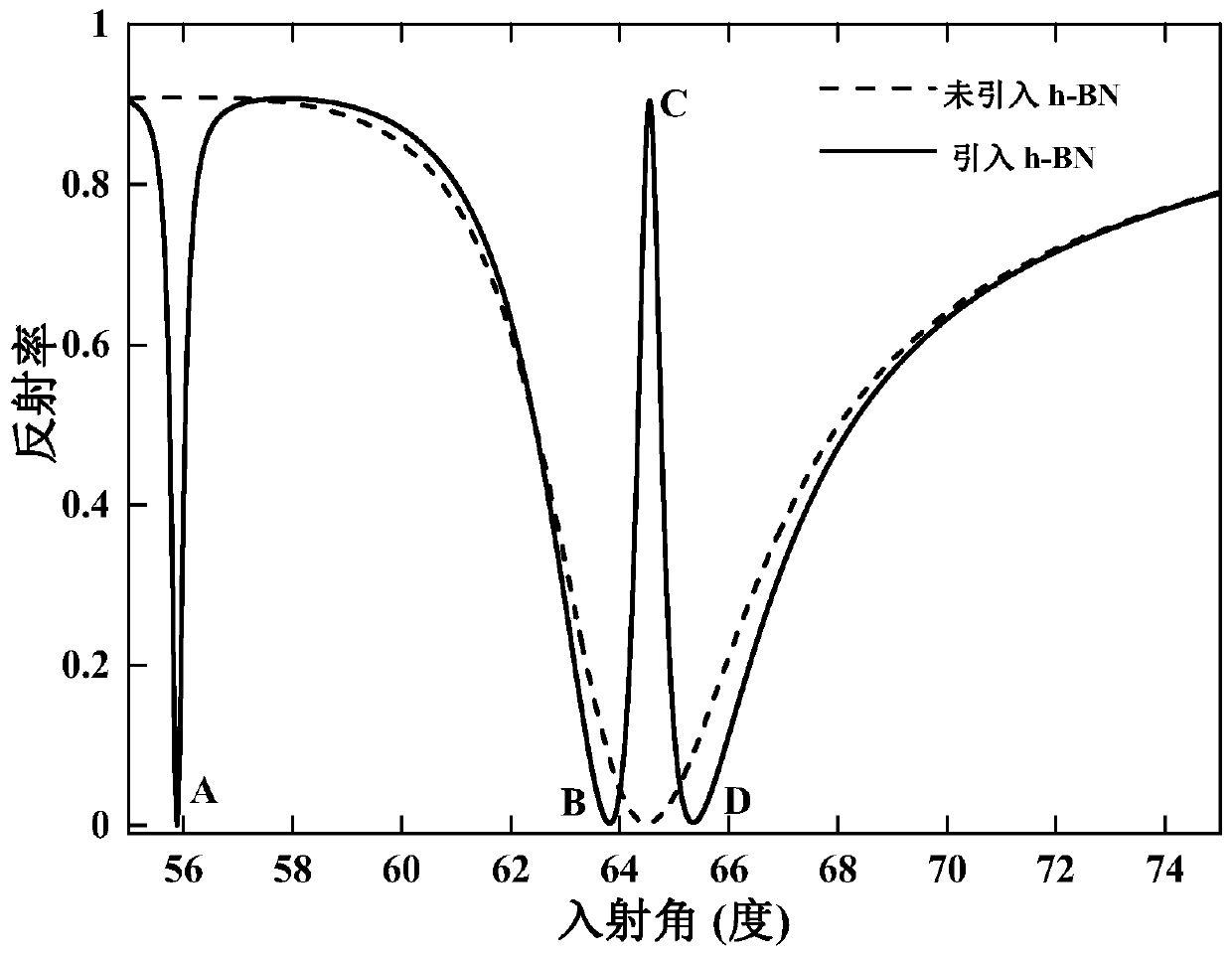

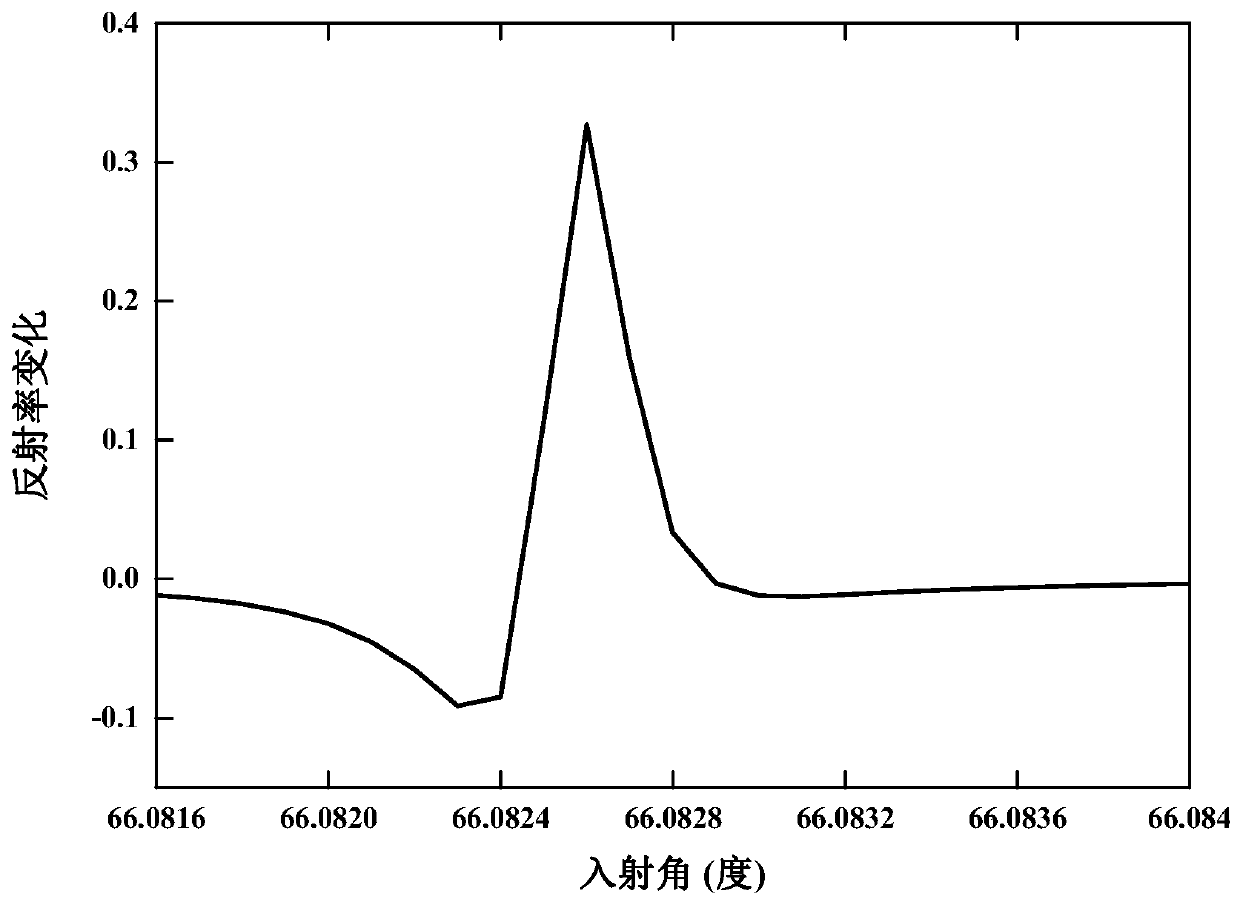

[0043] The invention utilizes the ultra-low plasmon loss characteristic of boron nitride to perform prism coupling test on the sensing chip. Since the two-dimensional structure material has the advantages of large surface area and many ...

Embodiment 1

[0045] The embodiment of the present invention provides a biosensor chip and a preparation method thereof.

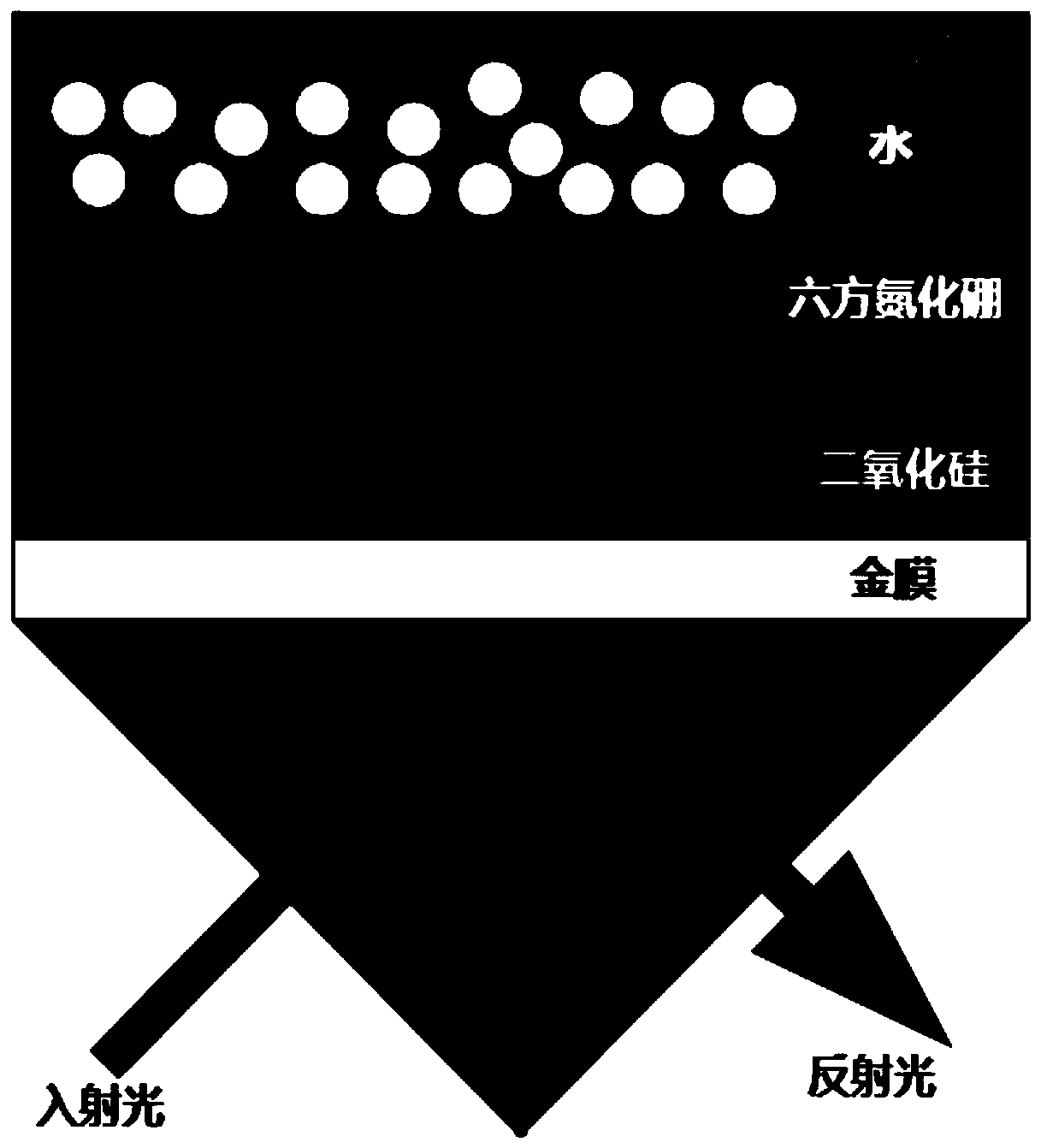

[0046] The biosensor chip includes:

[0047] 48nm gold base film;

[0048] 450nm silica coupling layer;

[0049] 650nm hexagonal boron nitride thin film is passed to the layer.

[0050] Described preparation method comprises:

[0051] First, a metal film with a thickness of 48nm is evaporated on the SF11 or BK7 prism section by physical vapor deposition method;

[0052] Then silicon dioxide was deposited to a thickness of 450 nm on the gold film by a plasma enhanced chemical vapor deposition (PECVD) system.

[0053] Finally, a hexagonal boron nitride material with a thickness of 650 nm was deposited on the silicon dioxide surface by chemical vapor deposition (Chemical Vapor Deposition, CVD).

[0054] Example 1

[0055] The embodiment of the present invention provides a biosensor chip and a preparation method thereof.

[0056] The biosensor chip includes:

[0057...

Embodiment 2

[0068] The embodiment of the present invention provides a biosensor chip and a preparation method thereof.

[0069] The biosensor chip includes:

[0070] 45nm silver-based film;

[0071] 100nm silicon dioxide coupling layer;

[0072] 800nm hexagonal boron nitride thin film is passed to the layer.

[0073] Described preparation method comprises:

[0074] First, a metal film with a thickness of 40nm is evaporated on the SF11 or BK7 prism section by physical vapor deposition method;

[0075] Silicon dioxide was then deposited on the gold film with a thickness of 100 nm by a plasma enhanced chemical vapor deposition (PECVD) system.

[0076] Finally, a hexagonal boron nitride material with a thickness of 800 nm was deposited on the silicon dioxide surface by chemical vapor deposition (Chemical Vapor Deposition, CVD).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com