a cnt-sio 2 /ci material preparation method and grinding device

A grinding device, the technology of cnt-sio2, applied in the field of rubber mixing, can solve the problems of re-agglomeration, large water consumption, long time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

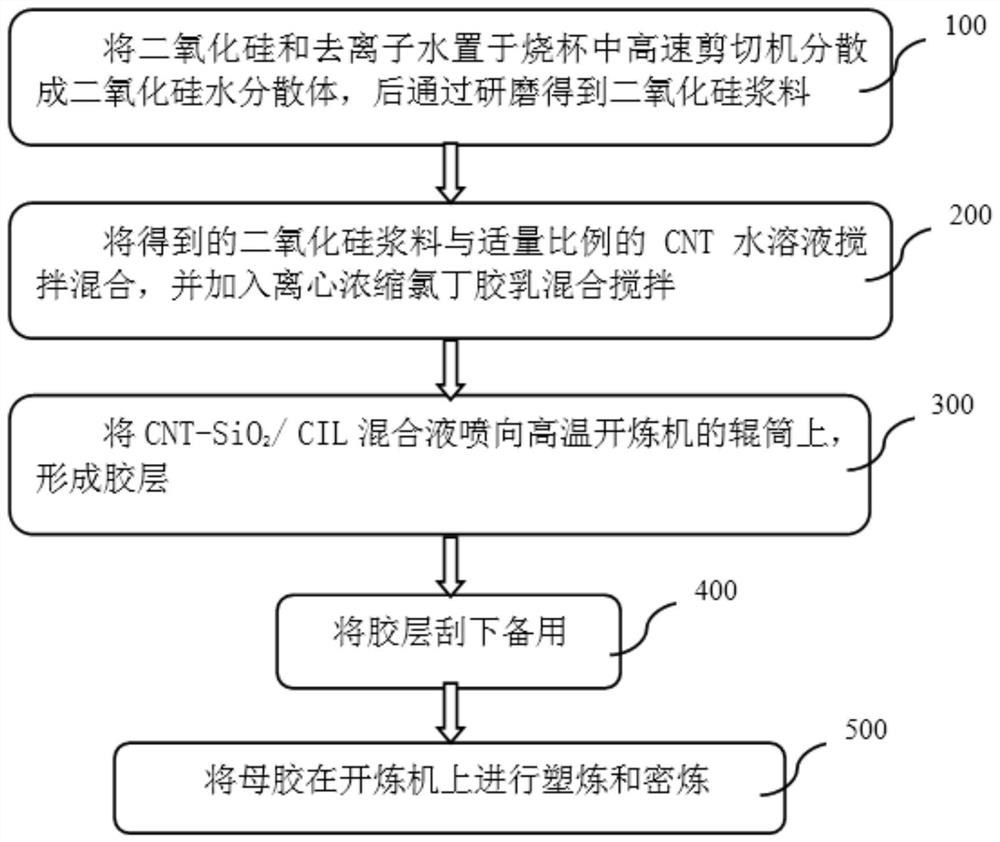

[0046] Such as figure 1 As shown, the present invention provides a CNT-SiO 2 / CI composite material preparation method, is characterized in that: comprises the steps:

[0047] S100, put silicon dioxide and deionized water in a beaker, and use a high-speed shearing machine to disperse into a silicon dioxide aqueous dispersion with a mass fraction of 25wt%, and then grind it through a grinder to obtain a mass fraction of 25wt% silica Silicon paste;

[0048] S200, stirring and mixing the obtained silica slurry with an appropriate proportion of CNT aqueous solution to form CNT-SiO 2 Mixed solution, and the mass fraction is 60wt% centrifuge concentrated neoprene latex to add CNT-SiO 2 Stir in the mixture to obtain CNT-SiO 2 / CIL mixture;

[0049] S300, the CNT-SiO 2 / CIL mixed solution is poured into the mill, and atomized and sprayed on the roller in the mill to form a glue layer;

[0050] S400, cooling the roller to 50-60°C, and after the adhesive layer is dry, use the scr...

Embodiment 2

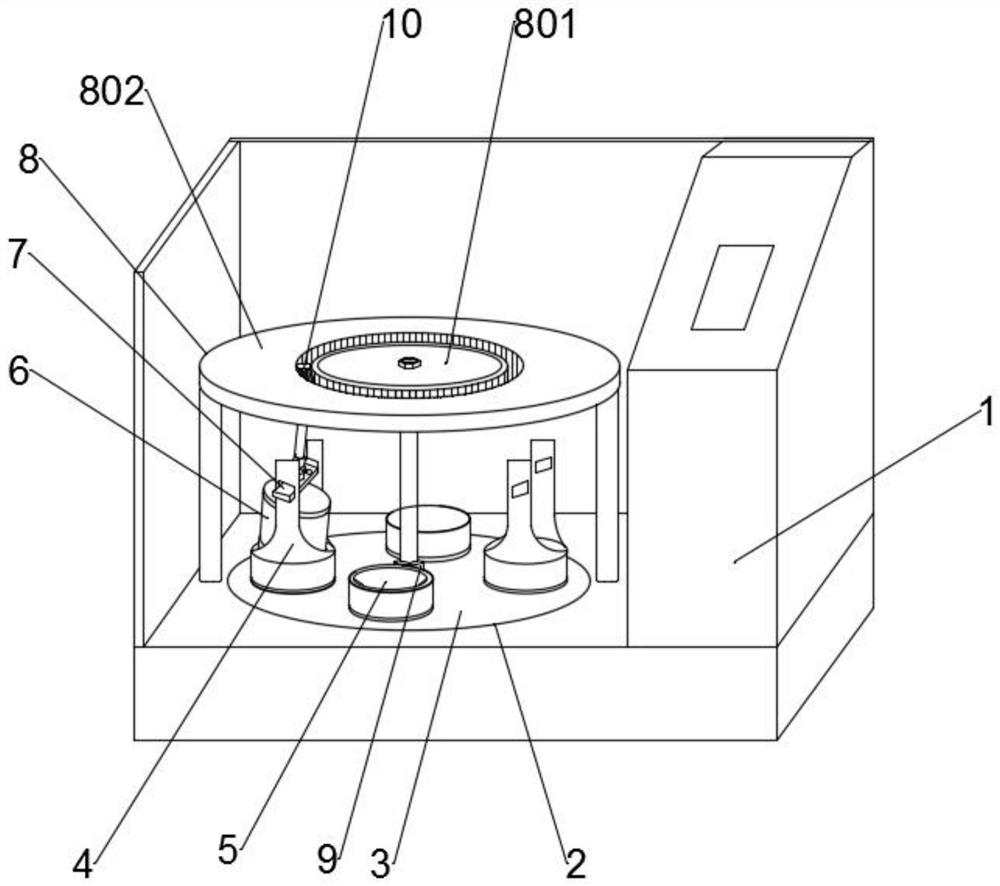

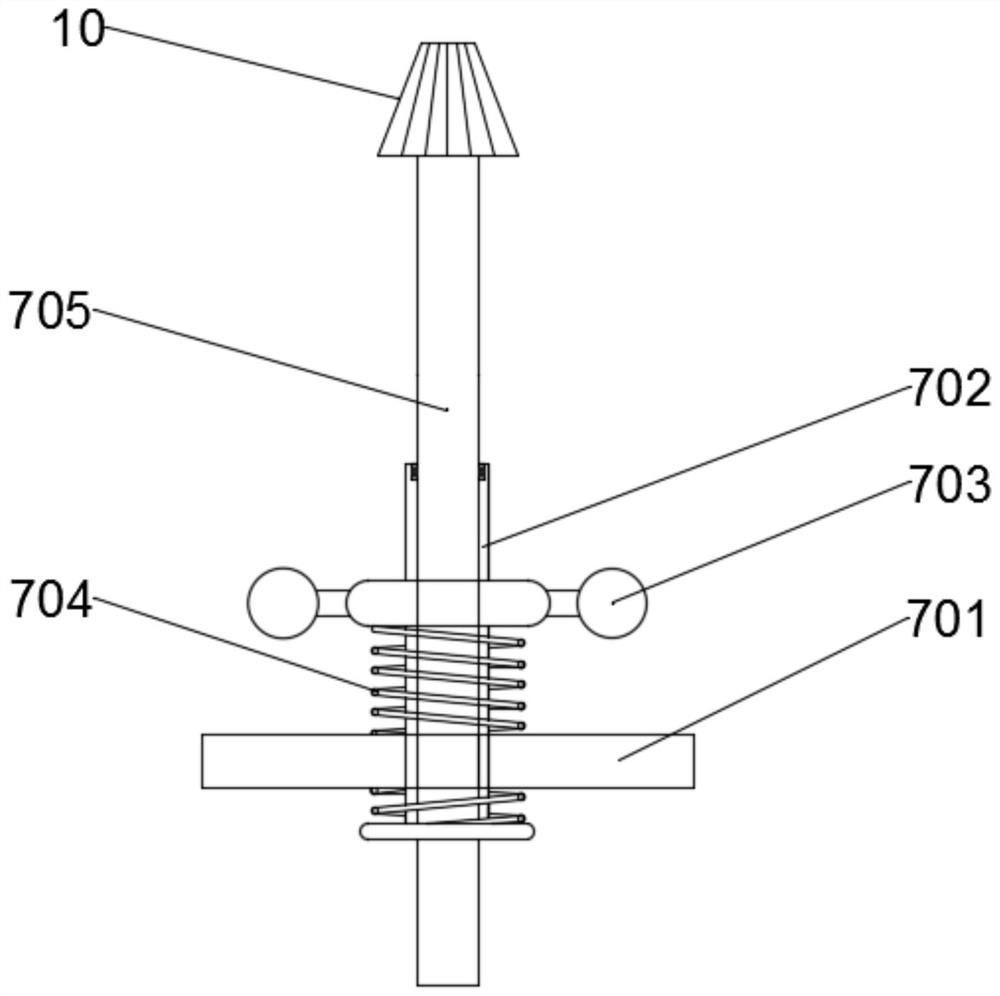

[0058] Such as figure 2 , image 3 and Figure 4 Shown, a kind of CNT-SiO used in embodiment 1 provided by the present invention 2 The grinding device made of / CI composite material includes a base 1 and a mounting groove 2 arranged on the base 1. A planetary wheel 3 driven by a motor is arranged inside the mounting groove 2, and there are at least three star wheels of the planetary wheel 3 , the star wheel of the planetary wheel 3 is provided with a fixed bracket 4, the fixed bracket 4 is equipped with a grinding tank 6 through a movable hinge device 5, a pressure rod device 7 is installed on the grinding tank 6, and a transfer disc 8 is arranged on the upper part of the grinding tank 6 , and the transfer disc 8 is fixedly connected to the installation groove 2 through a bracket, the transfer disc 8 includes an inner wheel disc 801 and an outer rail ring 802, and the opposite surfaces of the inner wheel disc 801 and the outer rail ring 802 are provided with racks, pressing...

Embodiment 3

[0070] For the high-temperature open mill used in Example 1, in order to ensure the uniform contact and connection of the internal molecules of the rubber material, and reduce the time of rubber mixing, so that the colloid can be formed faster, the high-temperature open mill is improved as follows:

[0071] Such as Figure 5 to Figure 8 As shown, the mill includes a base A1 and a front roller A2 and a rear roller A3 installed on the base A1. The tops of the front roller A2 and the rear roller A3 are movably installed with a cover plate A5 through a rail bar A4. The two ends of the plate A5 are provided with a micro-movement assembly A6 that drives the cover plate A5 to reciprocate on the guide rail rod A4, and the rubber material tube A7 is installed in the middle of the top of the cover plate A5, and the rubber material tube A7 includes the material storage tube A8 and the material supply tube A9, the connecting pipe between the storage pipe A8 and the feeding pipe A9 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com