Preparation method of temperature-sensitive hydrogel precursor

A temperature-sensitive hydrogel and precursor technology, applied in the field of hydrogel, can solve the problems of temperature-sensitive hydrogel material limitations, low mechanical strength, and rapid hydrogel erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

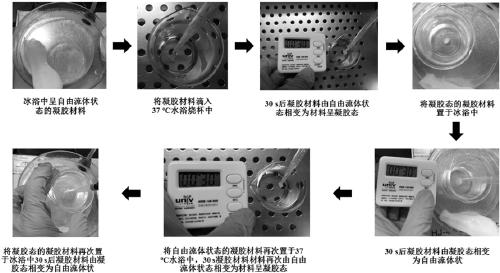

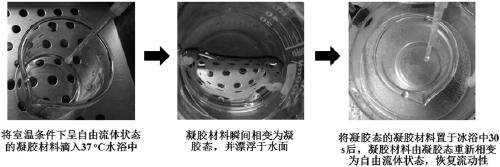

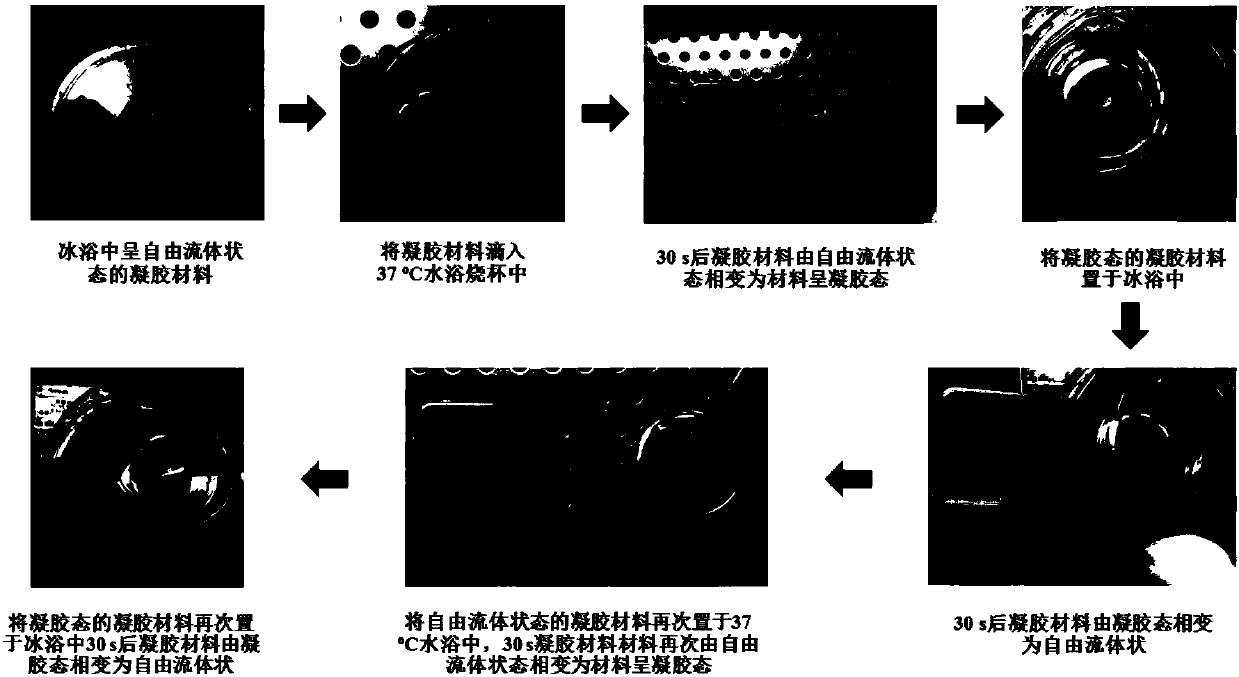

Image

Examples

preparation example Construction

[0014] The embodiment of the present invention provides a method for preparing a temperature-sensitive hydrogel precursor, which includes:

[0015] S1. The biological material is fully dissolved under the condition that the molecule is non-electrically neutral to obtain a biological material solution.

[0016] Wherein, the biological material includes at least one of natural biological material and synthetic biological material. Natural biomaterials include starchy materials, cellulose-based materials, alginic acid, alginate, serum albumin, fibrinogen, hyaluronic acid, isinglass, chitosan, chitosan / disodium glycerophosphate mixture, At least one of thromboplastin, collagen, gelatin, herringin, keratins, and reduced keratin. Starch materials include starch and starch derivatives, and cellulose materials include cellulose and cellulose derivatives. The synthetic biological material includes at least one of polyamino acid, polyvinyl alcohol, polyethylene glycol, acrylic acid, a...

Embodiment 1

[0038] This embodiment provides a thermosensitive hydrogel precursor, and its preparation method is as follows:

[0039] S1. Stir and mix the isinglass and hydrochloric acid solution evenly at 8° C. to prepare a isinglass solution with a isinglass content of 1 wt%.

[0040] S2. Maintain stirring at -1°C, slowly add NaOH solution dropwise to the isinglass solution, and adjust the pH value of the isinglass solution to 5.1.

[0041] S3. Continue stirring at 1° C., and slowly add a pH value stabilizer to the above isinglass solution, the addition method is 2 wt % per minute, and the addition is completed in 50 minutes.

[0042] The specific ion / molecule pair contained in this pH stabilizer is Tris-H + , after the addition, Tris-H in the solution + The concentration is 10M. In order to precisely control the pH value of the solution, NaOH solution was further added dropwise to ensure that the pH range of the solution was 5.5±1.

Embodiment 2

[0044] This embodiment provides a thermosensitive hydrogel precursor, and its preparation method is as follows:

[0045] S1. Stir and mix chitosan, sodium alginate and ammonia solution evenly to form a solution with chitosan content of 10wt% and sodium alginate content of 0.01wt%.

[0046]S2. Maintain stirring at 4° C., slowly add citric acid solution dropwise to the above solution, and adjust the pH value of the solution to 8.3.

[0047] S3. Continue to stir at -2°C, and slowly add a pH value stabilizer to the above solution, the addition method is 5 wt% per minute, and the addition is completed in 30 minutes.

[0048] The specific ion / molecule pair contained in this pH stabilizer is NH 4 + -NH 3 and HPO 4 2- -H + - Triethylamine, after addition, NH in solution 4 + -NH 3 The concentration is 5M, HPO in solution 4 2- -H + - The concentration of triethylamine is 0.01M. The pH range of the solution was 7.8±1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com