High-temperature-resistant composite proton exchange membrane and preparation method thereof

A proton exchange membrane and composite technology, which can be used in the manufacture of final products, sustainable manufacturing/processing, fuel cells, etc., can solve the problems of limiting proton conductivity, reducing membrane toughness, and detrimental to the comprehensive performance of high temperature proton exchange membranes. Wide applicability, improved mechanical strength, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Blend 0.06mol 3,4-dimethylphenyl-p-benzoquinone, 0.06mol 4,4-dihydroxydiphenyl sulfone, 0.12mol 4,4'-difluorobenzophenone and 0.15mol potassium carbonate in Under a nitrogen atmosphere, use 100ml sulfolane as a solvent and 30ml toluene as a water-carrying agent, heat up to 140°C with water for 3 hours, then distill off the toluene, and then heat up to 180°C for 4 hours. After the reaction, the mixed solution was poured into deionized water to obtain a white strip polymer. Break the strip polymer into a powder with a tissue grinder, boil and wash it with acetone several times to remove the solvent, and wash it repeatedly with distilled water to remove the salt, and then put it in an oven for 24 hours at 60°C to obtain a pure white powder. The solid, that is, side-chain dimethylphenyl type polyarylether (dmPA, the structure of which is shown below), was 46.3 g, and the yield was 94%.

[0040]

[0041] Weigh 8.20g of DMPA obtained above, 4.45g (0.025mol) of N-bromosucc...

Embodiment 2

[0045] Use the same method as in Example 1 to prepare dmPA to synthesize side chain p-methylphenyl type polyarylether (mPA, its structure is as follows), except that 0.06mol p-methylphenyl-p-benzoquinone is used to replace 0.06mol 3,4 -Dimethylphenyl-p-benzoquinone, the yield of mPA obtained is 44.5 g, the yield is 92%.

[0046]

[0047] The same method as in Example 1 to prepare BrdmPA is used to prepare side chain-containing benzyl bromide p-methylphenyl type polyarylether—BrmPA, the difference is that 8.06g mPA is used to replace 8.20g dmPA, and the resulting BrmPA output is 8.50g, with an average per The mole benzyl position contains 0.92 mole bromine.

[0048] The method for preparing BrdmPA-c-PBI in Example 1 is used to prepare the side chain-containing benzyl bromide p-methylphenyl type polyarylether and polybenzimidazole composite cross-linked membrane (BrmPA-c-PBI), the difference is that BrmPA replaces BrdmPA.

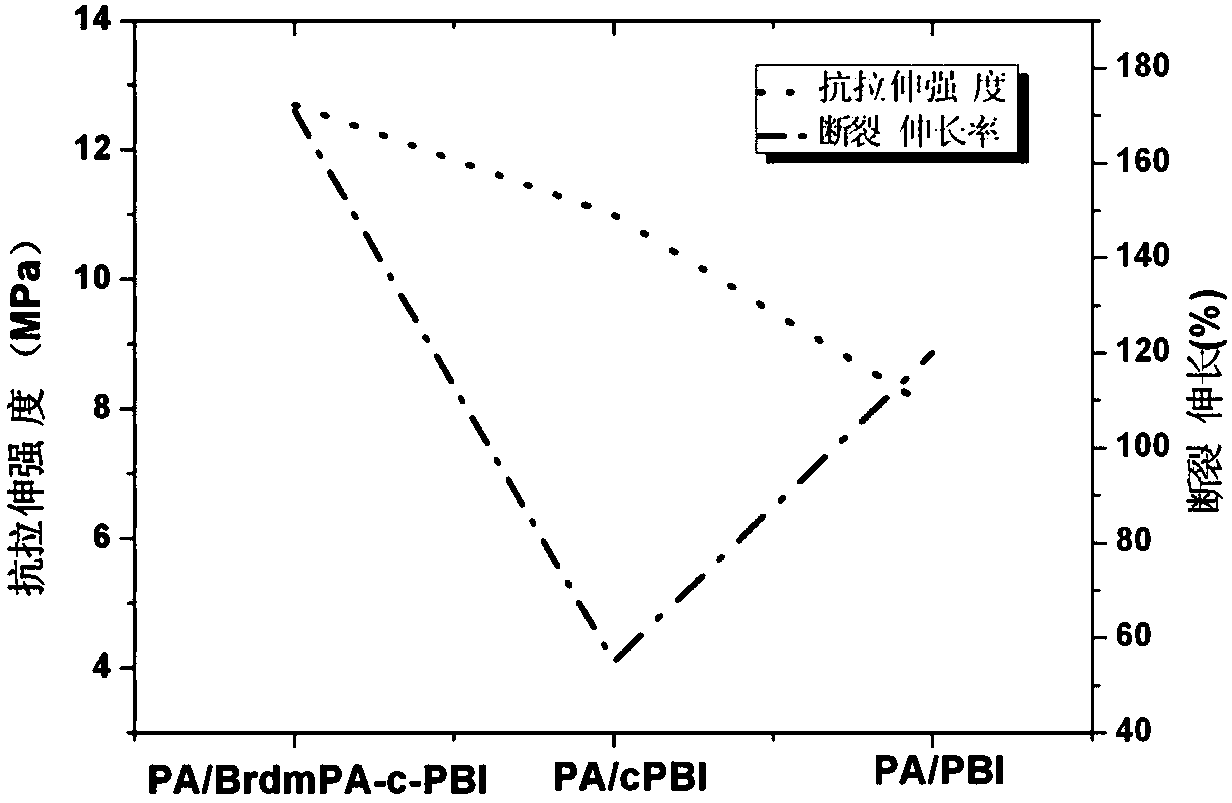

[0049] Adopt the method for preparing PA / BrdmPA-c-PB...

Embodiment 3

[0051] Weigh 30g of mPBI solution (10wt% solid content), pour the solution onto a glass plate, cast it on a glass plate and dry it thoroughly in an oven at 80°C, continue heating at 150°C for 5h, and finally remove it from the glass plate to obtain a PBI film.

[0052] Take a 4*4cm PBI membrane and soak it in 85wt% phosphoric acid solution, soak it at 80°C for 24 hours, remove excess phosphoric acid on the surface with filter paper, and obtain a phosphoric acid doped membrane using polybenzimidazole (PA / PBI). The phosphoric acid doping level was 12.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com