Rechargeable battery using proton embedded compound

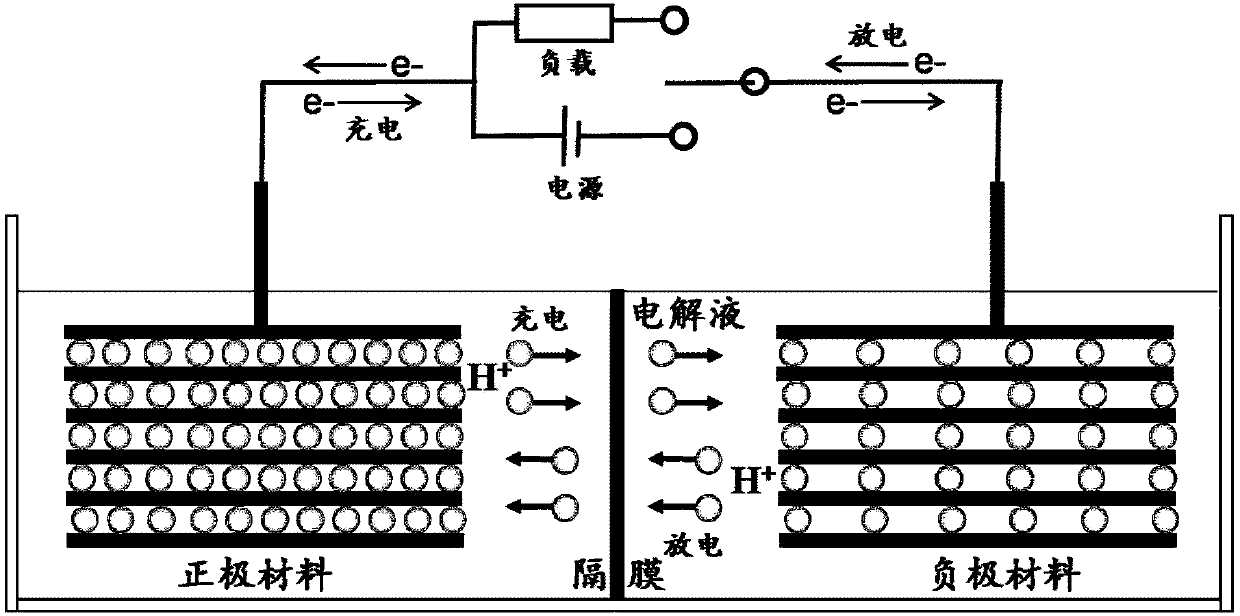

A technology of embedding compounds and rechargeable batteries, which is applied in the direction of non-aqueous electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of low specific energy and specific power, limited applications, and poor rapid charge and discharge capabilities, and achieve light weight, Effects of improving safety and improving high-current charge-discharge capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

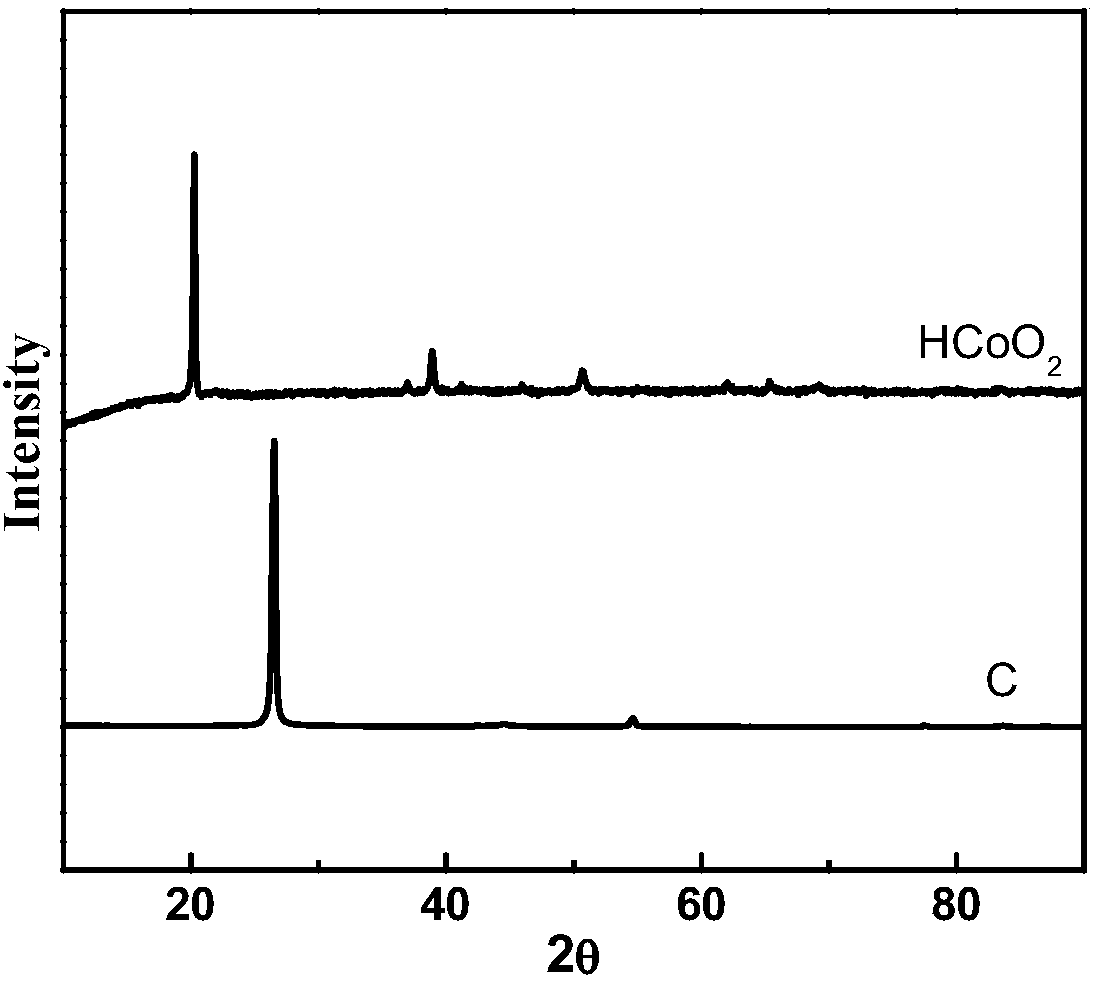

[0038] HCoO 2 (~5um, spherical) is the positive electrode material, graphite (~15um, spherical) is the negative electrode material, 1-ethyl-3-methyl-imidazole tetrafluoroborate is the electrolyte, and the polypropylene / polyethylene / polypropylene film is The diaphragm, the positive electrode current collector is metal aluminum foil, and the negative electrode current collector is metal copper foil. Positive electrode preparation: with HCoO 2 : Acetylene black: PVDF=8:1:1 (mass ratio, the same below), NMP is used as a dispersant, coated on metal aluminum foil, and a positive electrode sheet with a thickness of 50um is prepared. Negative electrode preparation: Graphite: acetylene black: PVDF = 8:1:1 (mass ratio, the same below), and NMP as a dispersant, coated on metal copper foil to prepare a negative electrode sheet with a thickness of 50um. In the glove box, the battery case is from bottom to top: negative electrode case, negative electrode sheet, electrolyte, separator, ele...

Embodiment 2

[0040] HFePO 4 (~20um, spherical) is the positive electrode, mesocarbon microspheres (~20um, spherical) are the negative electrode, polystyrene sulfonic acid is the electrolyte, polypropylene resin non-woven fabric is the separator, the positive electrode current collector is metal aluminum foil, and the negative electrode current collector For nickel foam. Positive electrode preparation: HFePO 4 : Acetylene black: PVDF = 8: 1: 1, NMP as a dispersant, coated on metal aluminum foil to prepare a positive electrode sheet with a thickness of 50um. Negative electrode preparation: mesophase carbon microspheres: acetylene black: PVDF = 8: 1: 1, NMP as a dispersant, coated on nickel foam to prepare a negative electrode sheet with a thickness of 50um. In the glove box, the battery case is from bottom to top: negative electrode case, negative electrode sheet, electrolyte, separator, electrolyte, positive electrode sheet and positive electrode case, packaged, and tested for electrochem...

Embodiment 3

[0042] Take HMn 2 o 4 (~600nm, octahedral shape) is the positive electrode, carbon nanotubes (diameter 40-60nm, length ~6um) are the negative electrode, perfluorosulfonic acid resin is the electrolyte and separator, the positive electrode current collector is metal aluminum foil, and the negative electrode current collector is carbon paper . Positive electrode preparation: with HMn 2 o 4 : Acetylene black: PVDF = 8: 1: 1, NMP as a dispersant, coated on metal aluminum foil to prepare a positive electrode sheet with a thickness of 50um. Negative electrode preparation: carbon nanotubes: acetylene black: PVDF=8:1:1, NMP as a dispersant, coated on carbon paper to prepare a negative electrode sheet with a thickness of 50um. In the glove box, the battery case is in order from bottom to top: negative electrode case, negative electrode sheet, electrolyte or separator, positive electrode sheet and positive electrode case, package, and test electrochemical performance. The battery p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com