Metal-doped CoP3 and preparation method and application thereof

A metal doping and metal technology, applied in the field of metal doped CoP3 preparation, can solve the problem of low intrinsic activity of cobalt triphosphide electrocatalytic hydrogen evolution, and achieve excellent electrocatalytic hydrogen evolution activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

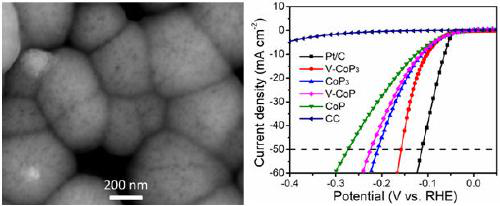

[0034] In this embodiment, the self-supporting growth of vanadium-doped cobalt triphosphide nanosphere electrodes on a flexible carbon cloth and the electrocatalytic hydrogen evolution test include the following steps:

[0035] The first step: first soak the flexible carbon cloth in dilute nitric acid with a mass fraction of 15% for two hours to protonate it, then take out the flexible carbon cloth and wash it with water and anhydrous three times, and dry for use.

[0036] In the second step, 1.309g of cobalt nitrate hexahydrate, 0.136g of vanadium sulfate heptahydrate and 0.2g of ammonium nitrate were sequentially dissolved in 15mL of water, stirred at room temperature for 60 minutes to obtain a uniform solution, and then 5mL of 25wt% ammonia water was added to the above The solution was stirred for thirty minutes to obtain a homogeneous solution.

[0037] In the third step, transfer the uniform solution from the previous step into the inner tank of the 25mL PTFE reactor, and put th...

Embodiment 2

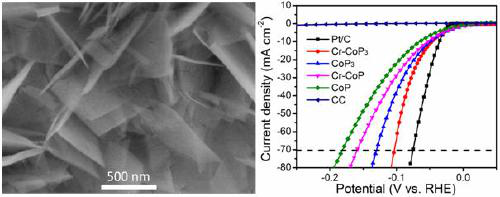

[0041] In this embodiment, self-supporting growth of chromium-doped cobalt triphosphide nanowire array electrodes on flexible carbon cloth and electrocatalytic hydrogen evolution test include the following steps

[0042] The first step: first soak the flexible carbon cloth in 15% dilute nitric acid for two hours to protonate it, then take out the flexible carbon cloth and wash it with water and alcohol three times and dry it for later use.

[0043] The second step: Dissolve 0.523 g cobalt nitrate hexahydrate, 0.078 g chromium sulfate, 0.186 g ammonium fluoride and 0.6 g urea in 40 mL ultrapure water, and stir for 30 minutes at room temperature to obtain a uniform solution.

[0044] The third step: transfer the homogeneous solution into the inner tank of a 50mL polytetrafluoroethylene reactor, and put the dry spare flexible carbon cloth into the inner tank of the reactor vertically, seal the reactor, and react hydrothermally at 120°C for 6 hours. The carbon cloth is taken out, the sur...

Embodiment 3

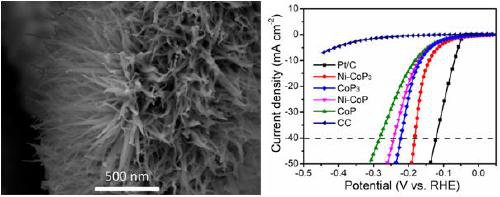

[0048] In this embodiment, the self-supporting growth of nickel-doped cobalt triphosphide nanosheet array electrodes on flexible carbon cloth and the electrocatalytic hydrogen evolution test include the following steps

[0049] The first step: first soak the flexible carbon cloth in dilute nitric acid with a mass fraction of 15% for two hours to protonate it, then take out the flexible carbon cloth and wash it with water and absolute ethanol three times and dry it for later use.

[0050] The second step: Dissolve 2.095 g of cobalt nitrate hexahydrate, 0.233 g of nickel nitrate hexahydrate, 0.106 g of ammonium fluoride and 1.2 g of urea in 40 mL of ultrapure water, and stir for 60 minutes at room temperature to obtain a uniform solution.

[0051] Step 3: Transfer the homogeneous solution into the inner tank of a 50mL PTFE reactor, and put the washed dry spare flexible carbon cloth into the inner tank of the reactor vertically, seal the reactor, and heat it with water at 120℃ After rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com