Supported bimetallic carbon-silicon composite catalyst and preparation method and application thereof

A carbon-silicon composite and catalyst technology, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as expensive separation processes, toxic acid waste, and equipment corrosion, and achieve high catalytic activity and equipment The effect of low requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] (1) Rice husk crushing: rice husk is washed with water, dried, crushed, and sieved to obtain rice husk powder with a particle size of 90nm;

[0030] (2) Rice husk acid treatment: The rice husk powder was refluxed in the reaction kettle with a solid-to-liquid ratio of 1:10 and a hydrochloric acid solution with a mass fraction of 10% for 2 h, and the reflux product was washed with deionized water, and dried overnight at 105°C to obtain Acid-treated rice husk powder;

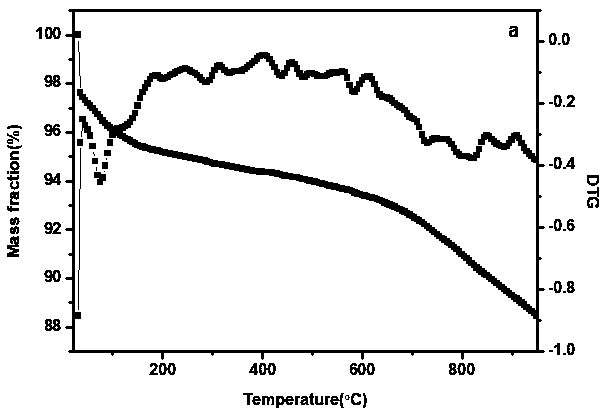

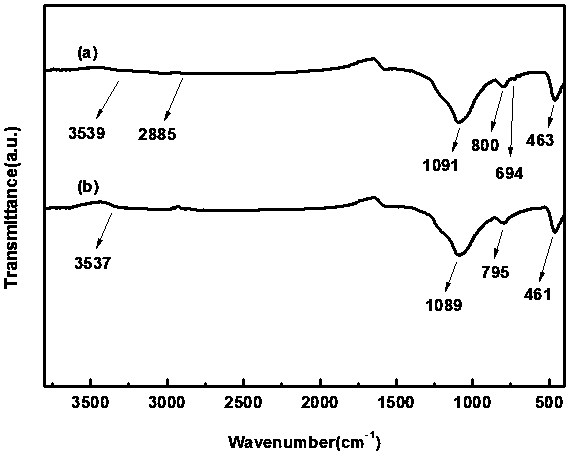

[0031] (3) Pyrolytic carbonization of rice husk: put the acid-treated rice husk powder in a quartz tube, put it into a tube furnace for pyrolytic carbonization at 500 °C, and raise the temperature from 20 °C to 500 °C at a rate of 5 °C / min. ℃, keep for 2 h, and transfer to the carbon-silicon composite support;

[0032] (4) Functionalization: Dissolve the carbon-silicon composite carrier in toluene in a narrow-mouth bottle at a solid-to-liquid ratio of ...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] (1) Rice husk crushing: rice husk is washed with water, dried, crushed, and sieved to obtain rice husk powder with a particle size of 80nm;

[0039] (2) Rice husk acid treatment: The rice husk powder was refluxed in the reaction kettle with a solid-to-liquid ratio of 1:10 and a hydrochloric acid solution with a mass fraction of 10% for 2 hours, and the reflux product was washed with deionized water (supplementary temperature 105°C) Drying in an oven to obtain acid-treated rice husk powder;

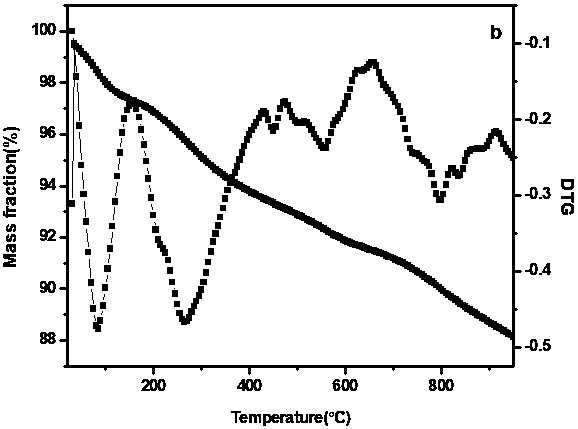

[0040] (3) Pyrolytic carbonization of rice husk: Put the acid-treated rice husk powder in a quartz tube and put it into a tube furnace for pyrolytic carbonization at 600 °C (from 20 °C to 600 °C at a rate of 5 °C / min. ℃, keep for 2 h. Supplementary time or other process conditions), to the carbon-silicon composite support;

[0041] (4) Functionalization: Dissolve the carbon-silicon composite carrier in toluene at a solid-to-li...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] (1) Rice husk crushing: rice husk is washed with water, dried, crushed, and sieved to obtain rice husk powder with a particle size of 70nm;

[0047] (2) Rice husk acid treatment: reflux the rice husk powder in a reaction kettle with a solid-to-liquid ratio of 1:10 and a hydrochloric acid solution with a mass fraction of 10% for 2 h, wash the reflux product with water, and dry to obtain acid-treated rice husk;

[0048] (3) Pyrolytic carbonization of rice husk: put the acid-treated rice husk in a quartz tube, put it into a tube furnace at 700°C for pyrolytic carbonization, and raise the temperature from 20°C to 700°C at a rate of 5°C / min , keep for 2 h. , to obtain a carbon-silicon composite carrier;

[0049] (4) Functionalization: Dissolve the carbon-silicon composite carrier in toluene in a narrow-mouthed bottle at a solid-to-liquid ratio of 1:9, and then add functionalized carrier 3-aminopropyltriethyl, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com