Method for producing graphite-enhanced-metal-based compound material preform through in-situ solidification of silica aerogel

An in-situ solidification and silicon airgel technology, which is applied in the field of metal matrix composites, can solve the problems of inaccurate control of preform size, inability to form near-net dimensions, poor uniformity of composite materials, etc., and achieve low energy consumption and low deformation small, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

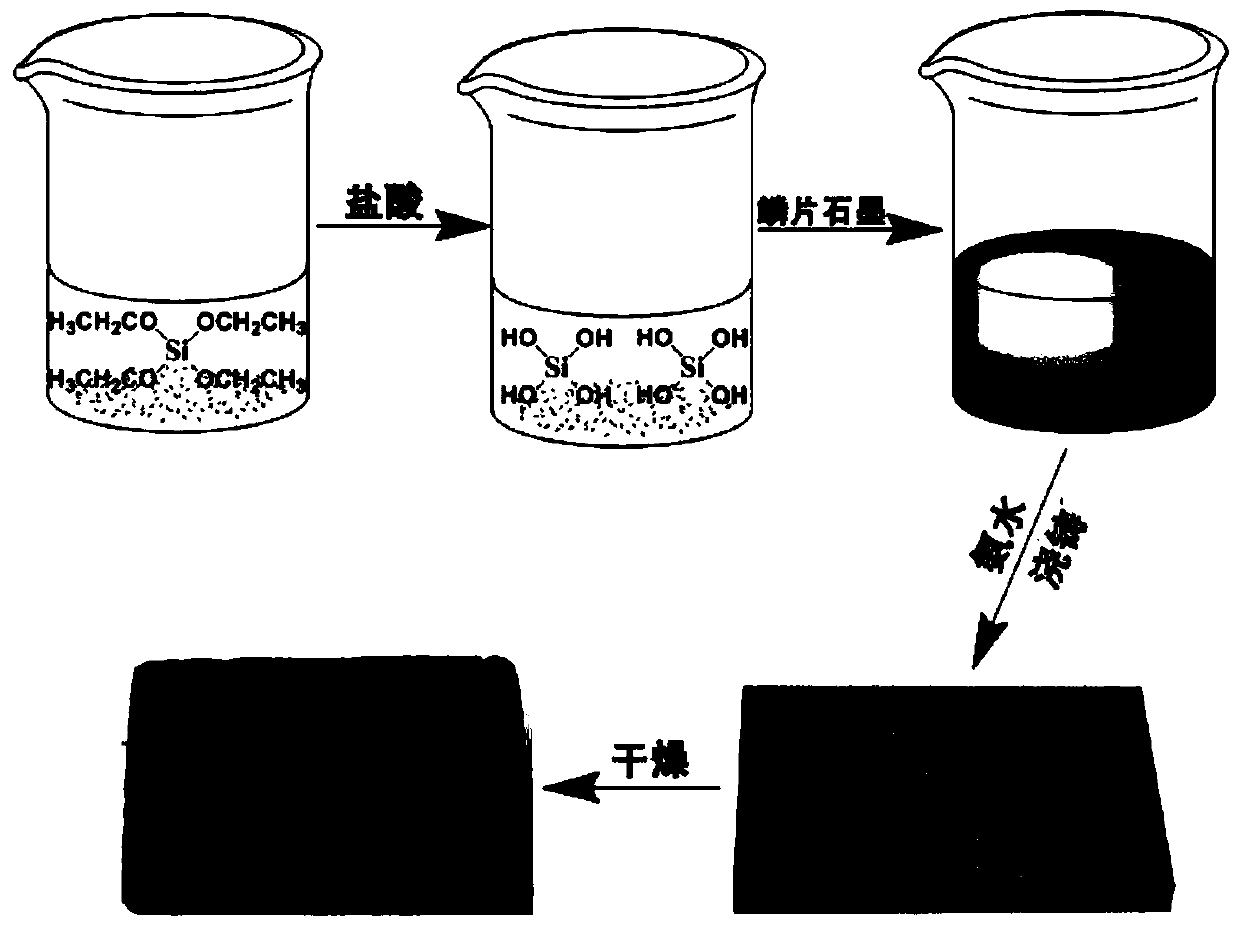

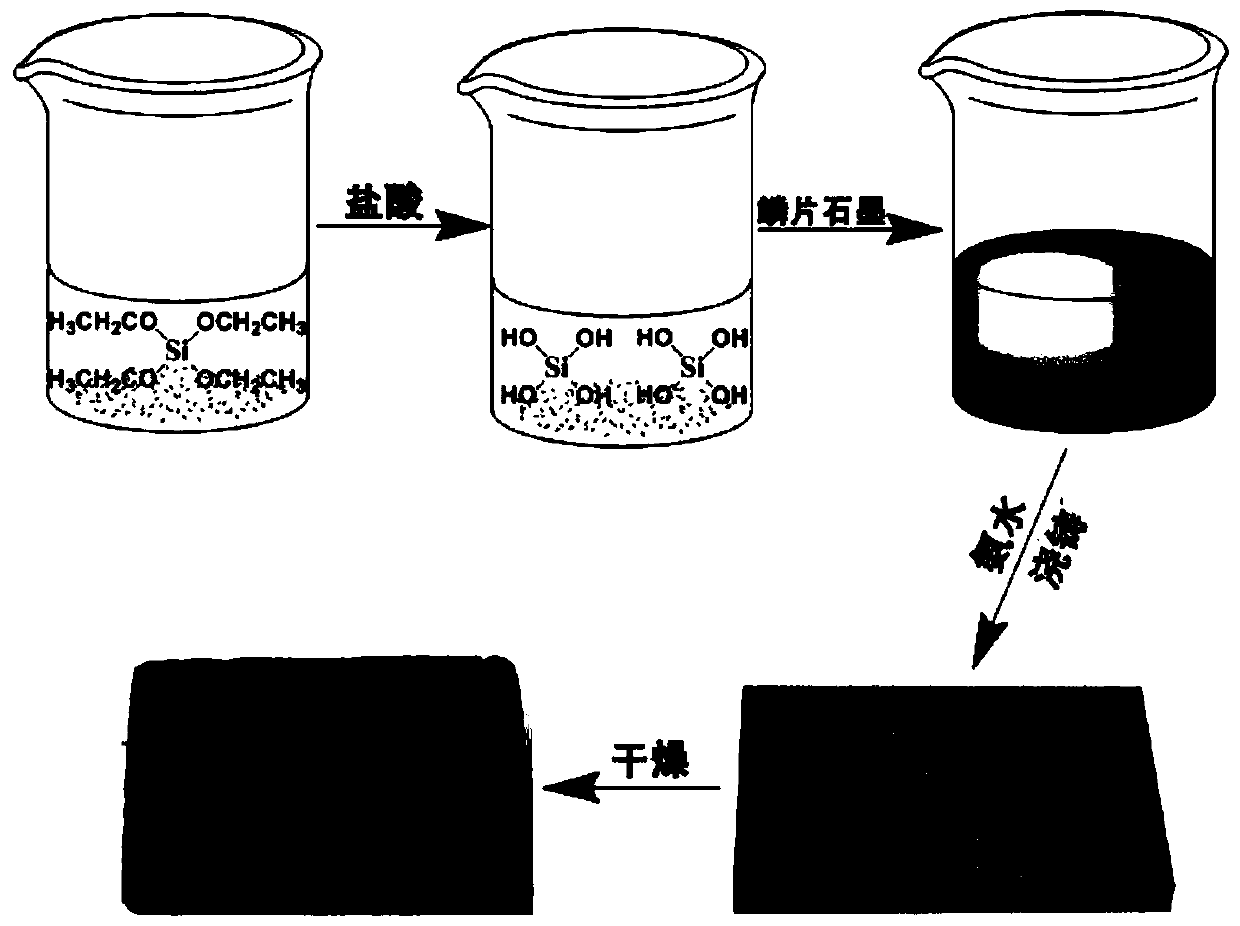

Embodiment 1

[0039] Example 1: 1. Weigh 100g of sodium hydroxide, 25g of anhydrous sodium carbonate, 25g of sodium phosphate, and 25g of 300-500 mesh flake graphite into a 1L beaker, add water to 1L, heat up to 100°C and stir for 15min, filter and use Wash with distilled water for 3 to 5 times, and dry for later use; ②. Pour the graphite in step ① into a beaker, add concentrated sulfuric acid until the graphite is submerged, heat up to 100°C and stir for 15 minutes, dilute with water, perform suction filtration, and then wash with distilled water for 3 ~5 times, dry for later use; ③, add 2ml tetraethyl orthosilicate, 10ml isopropanol, 0.5ml N,N-dimethylformamide, 0.6ml deionized water, 0.01ml hydrochloric acid into the beaker, hydrolyze After 2 hours, add 10g of graphite in step ②, and stir evenly; ④, add 0.04ml of ammonia water into the beaker, stir evenly, pour it into the mold, wait for the gel to release the mold; ⑤, put the green body in a drying oven to heat up Keep the temperature a...

Embodiment 2

[0040]Example 2: ①. Weigh 100g of sodium hydroxide, 25g of anhydrous sodium carbonate, 25g of sodium phosphate, and 25g of 300-500 mesh flake graphite into a 1L beaker. Wash with distilled water for 3 to 5 times, and dry for later use; ②. Pour the graphite in step ① into a beaker, add concentrated sulfuric acid until the graphite is submerged, heat up to 100°C and stir for 15 minutes, dilute with water, perform suction filtration, and then wash with distilled water for 3 ~5 times, dry for later use; ③, add 2ml tetraethyl orthosilicate, 10ml isopropanol, 0.5ml N,N-dimethylformamide, 0.6ml deionized water, 10ml hydrochloric acid into the beaker, hydrolyze for 2 hours Finally, add 11g of graphite in step ②, and stir evenly; ④, add 40ml of ammonia water into the beaker, stir evenly, pour it into the mold, and wait for the gel to demould; ⑤, put the green body in a drying oven and heat up to 80 ℃ for 6 hours, the temperature was raised to 110 ℃ for 6 hours, and the temperature was ...

Embodiment 3

[0041] Example 3: 1. Weigh 100g of sodium hydroxide, 25g of anhydrous sodium carbonate, 25g of sodium phosphate, and 25g of flake graphite of 300-500 mesh into a 1L beaker. Wash with distilled water for 3 to 5 times, and dry for later use; ②. Pour the graphite in step ① into a beaker, add concentrated sulfuric acid until the graphite is submerged, heat up to 100°C and stir for 15 minutes, dilute with water, perform suction filtration, and then wash with distilled water for 3 ~5 times, dry for later use; ③, add 2ml tetraethyl orthosilicate, 10ml isopropanol, 0.5ml N,N-dimethylformamide, 0.6ml deionized water, 10ml hydrochloric acid into the beaker, hydrolyze for 2 hours Finally, add 12g of graphite in step ②, and stir evenly; ④, add 40ml of ammonia water into the beaker, stir evenly, pour it into the mold, wait for the gel to be demoulded; ⑤, put the green body in a drying oven and heat up to 80 ℃ for 6 hours, the temperature was raised to 110 ℃ for 6 hours, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com