High-efficiency ternary organic solar cell and preparation method thereof

An organic solar cell, high-efficiency technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of weak absorption, achieve the effects of modifying the shape, broadening the optical absorption spectrum, and increasing the short-circuit current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

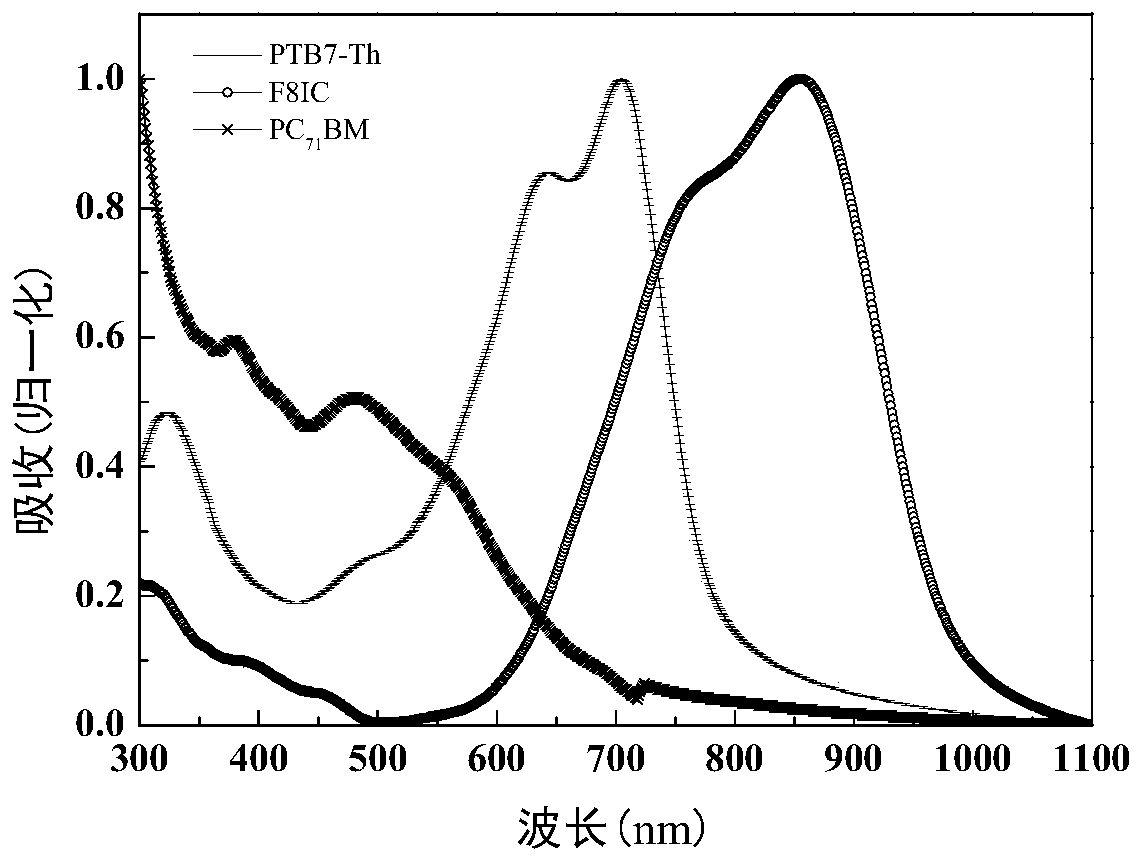

Problems solved by technology

Method used

Image

Examples

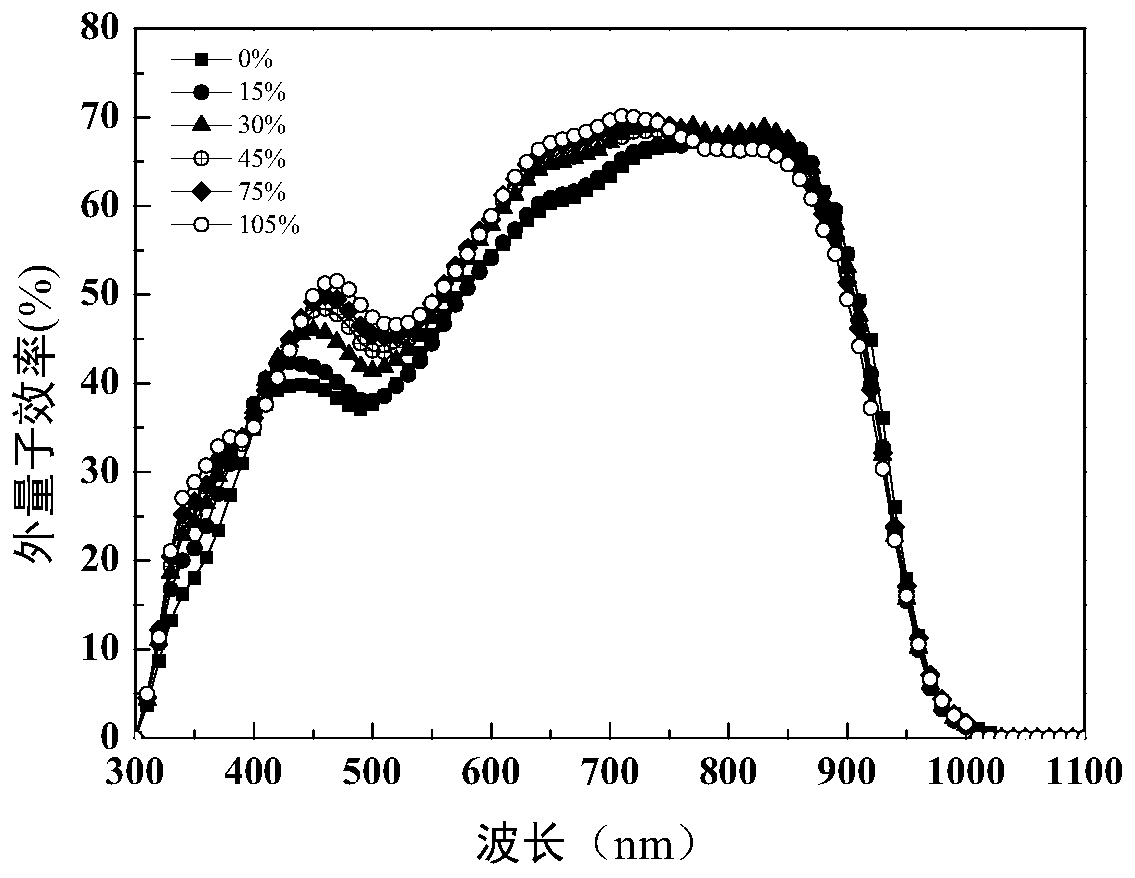

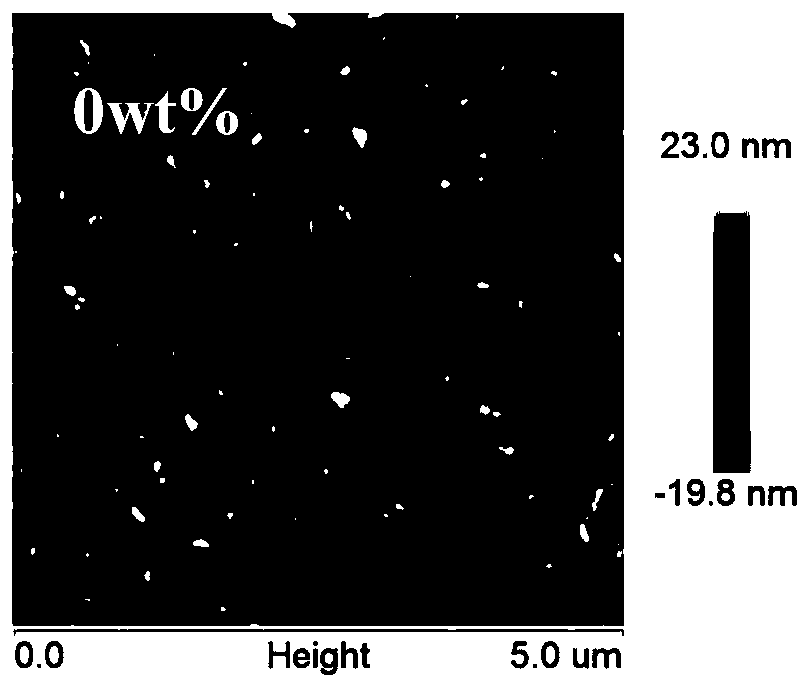

Embodiment 1

[0040] Engraving on the reverse side of the ITO-containing substrate is convenient for subsequent experiments. Subsequently, the etched ITO substrate was ultrasonically cleaned with isopropanol, detergent, ultrapure water, and isopropanol. Each step lasted 15 minutes. After completion, it was placed in an oven at 70°C for drying. Before the experiment, the slices were subjected to O 2 The purpose of the plasma treatment is to complete the further cleaning of the sheet, and then spin-coat a layer of electron transport layer ZnO on the surface of the ITO at a speed of 2500rpm for 45s. Finally, a ZnO layer with a thickness of 40 nm is produced. Then the sheet was transferred to a glove box filled with nitrogen, and the blend solution (solvent was chlorobenzene) with PTB7-Th:F8IC=1:1.5 (mass ratio) and donor concentration of 10mg / mL was placed in ZnO at a speed of 3000rpm. A film was formed by spin-coating to obtain a blend film with a thickness of 100 nm. Finally, place the fi...

Embodiment 2

[0043] Engraving on the reverse side of the ITO-containing substrate is convenient for subsequent experiments. Subsequently, the etched ITO substrate was ultrasonically cleaned with isopropanol, detergent, ultrapure water, and isopropanol. Each step lasted 15 minutes. After completion, it was placed in an oven at 70°C for drying. Before the experiment, the slices were subjected to O 2 The purpose of the plasma treatment is to complete the further cleaning of the sheet, and then spin-coat a layer of electron transport layer ZnO on the surface of the ITO at a speed of 2500rpm for 45s. After completion, place it on a heating platform at 200°C for 1h. Finally, a ZnO layer with a thickness of 40 nm is produced. The slides were then transferred to a nitrogen-filled glove box, and the PTB7-Th:F8IC:PC 71 BM=1:1.5:0.15 (mass ratio, 15wt% PC 71 BM), a ternary blend solution with a donor concentration of 10 mg / mL (the solvent is chlorobenzene) was spin-coated on ZnO at a speed of 3000...

Embodiment 3

[0046] Engraving on the reverse side of the ITO-containing substrate is convenient for subsequent experiments. Subsequently, the etched ITO substrate was ultrasonically cleaned with isopropanol, detergent, ultrapure water, and isopropanol. Each step lasted 15 minutes. After completion, it was placed in an oven at 70°C for drying. Before the experiment, the slices were subjected to O 2 The purpose of the plasma treatment is to complete the further cleaning of the sheet, and then spin-coat a layer of electron transport layer ZnO on the surface of the ITO at a speed of 2500rpm for 45s. After completion, place it on a heating platform at 200°C for 1h. Finally, a ZnO layer with a thickness of 40 nm is produced. The slides were then transferred to a nitrogen-filled glove box, and the PTB7-Th:F8IC:PC 71 BM=1:1.5:0.30 (mass ratio, 30wt%), the ternary blending solution (solvent is chlorobenzene) that the donor concentration is 10mg / mL is spin-coated on ZnO with the rotating speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com