Nano silicon dioxide/polymer material guided bone regeneration composite porous membrane and preparation method thereof

A technology of nano-silica and polymer materials, applied in tissue regeneration, medical science, prostheses, etc., can solve the problem of slow degradation rate, increased probability of allergic reaction of patients to guided bone regeneration membrane, hydrophobicity and slow degradation rate, cell Low adhesion and other problems, to achieve the effect of improving cell adhesion, increasing dielectric constant, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A nano-silica / polymer material guided bone regeneration composite porous film, the thickness is 0.1mm, the mass ratio of nano-silica and polymer material is 1:2; the polymer material is poly N-isopropyl Acrylamide-polycaprolactone-polyethylene glycol copolymer;

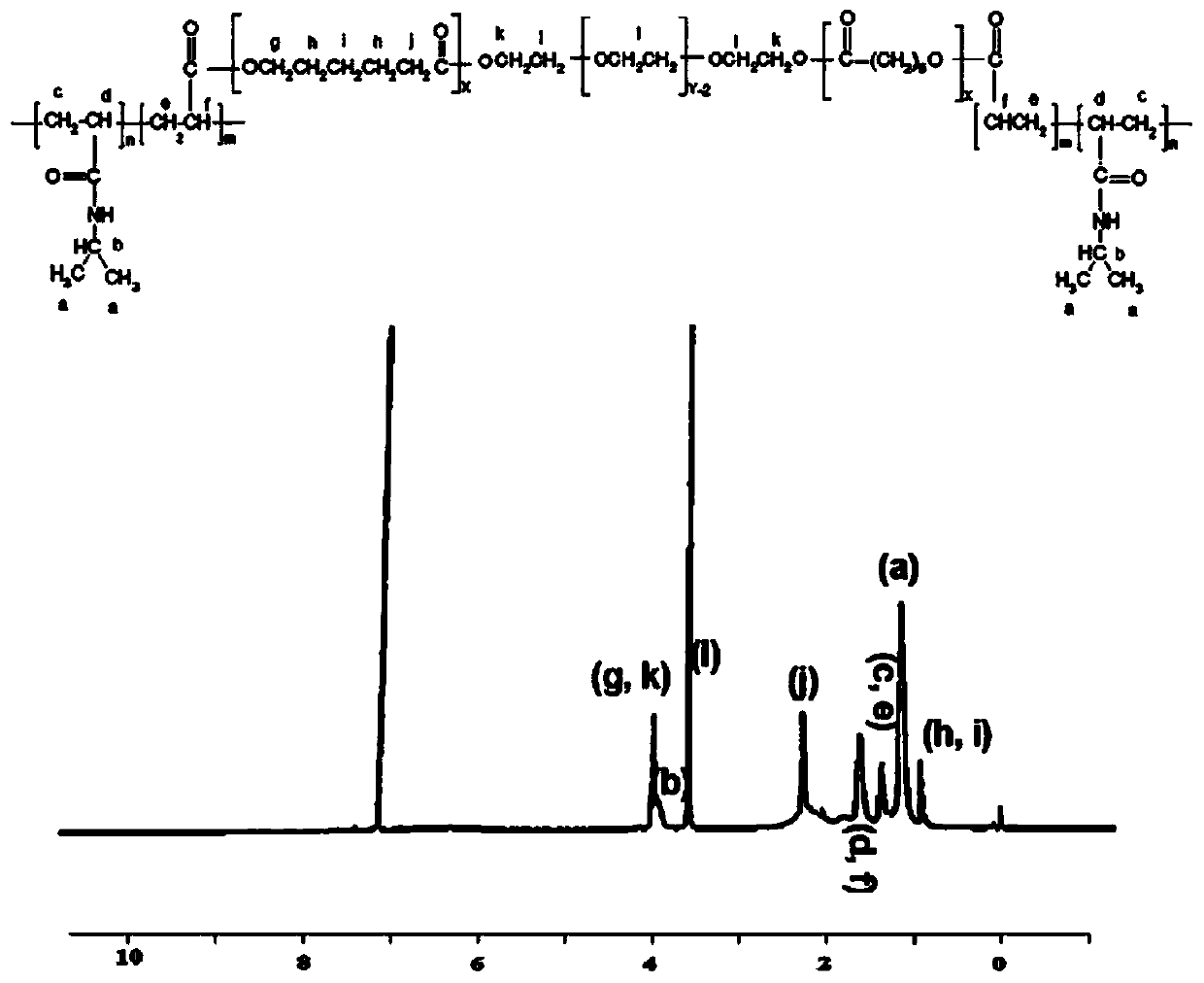

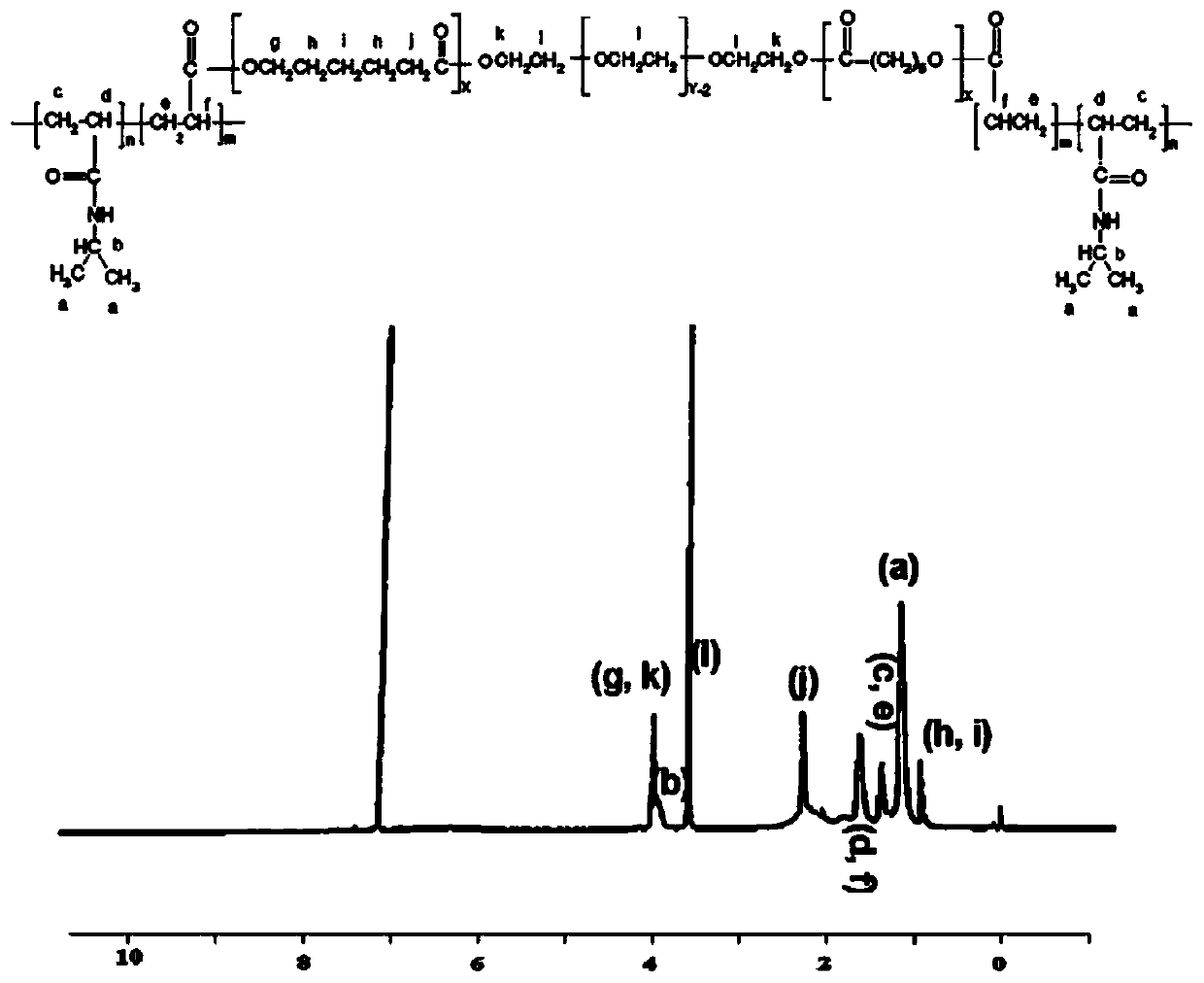

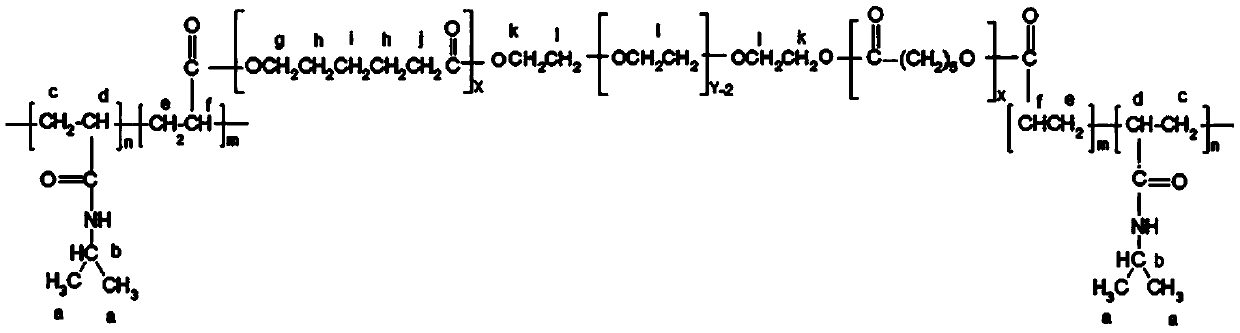

[0035] Wherein poly-N-isopropylacrylamide-polycaprolactone-polyethylene glycol copolymer is prepared according to the following steps:

[0036] ①Add 3kgε-caprolactone, 1kg polyethylene glycol and 0.01kg stannous octoate to the reaction bottle to dissolve in the solvent, blow nitrogen gas, stir and react at 125°C for 8 hours to obtain a reaction solution, and dissolve the reaction solution in water , dialyzed for 2 days, and the dialysate was freeze-dried to obtain polycaprolactone-polyethylene glycol copolymer;

[0037] ② Take 1.5kg of polycaprolactone-polyethylene glycol copolymer obtained in step ① and dissolve it in an organic solvent, add 0.3kg of triethylamine and 0.3kg of acryloyl chloride at 0°C, raise ...

Embodiment 2

[0040] A nano-silica / polymer material guided bone regeneration composite porous film, the thickness is 0.3mm, the mass ratio of nano-silica and polymer material is 1:4; the polymer material is polycaprolactone and poly Lactic acid is composed according to the mass ratio of 1:3.

Embodiment 3

[0042] A nano-silica / polymer material guided bone regeneration composite porous film, with a thickness of 0.15 mm, and a mass ratio of nano-silica to polymer material of 1:2.5; the polymer material is polylactic acid and collagen by mass The ratio is 1:1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com