Activated carbon regeneration device and method based on self-sustaining combustion

A regeneration device, activated carbon technology, applied in separation methods, filter regeneration, combustible gas purification, etc., can solve the problems of difficult to guarantee the uniformity of regeneration effect, high energy consumption of heating regeneration method, harsh regeneration conditions, etc., to shorten the heat transfer. Time required, efficient regeneration, fast regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

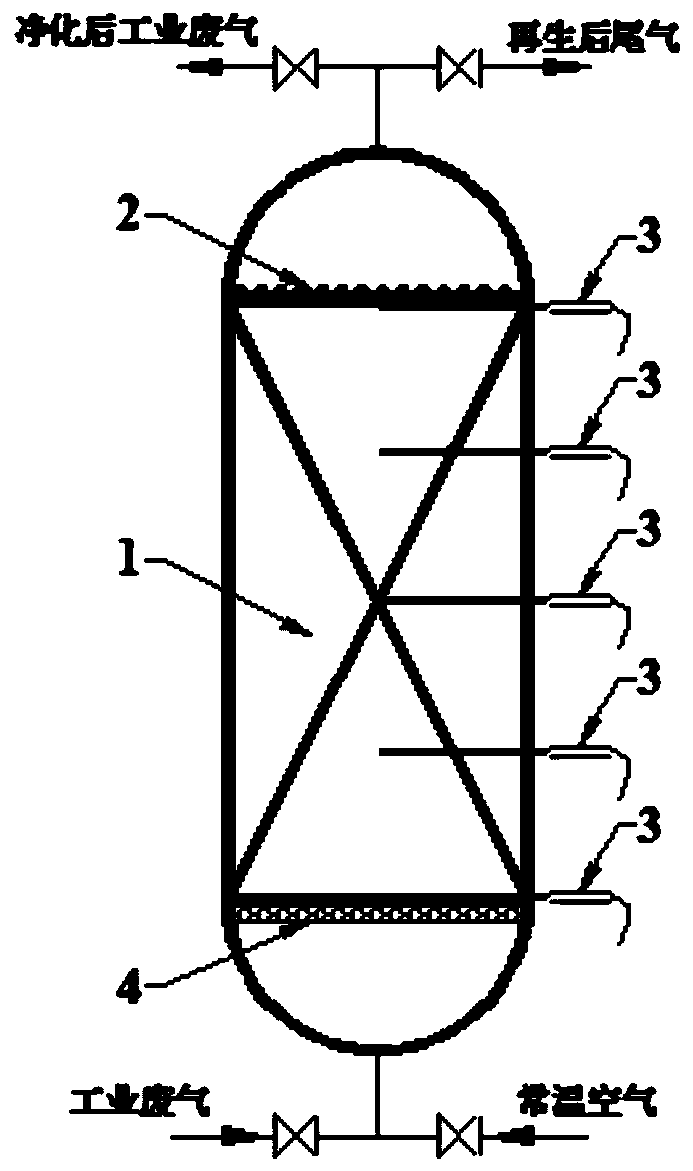

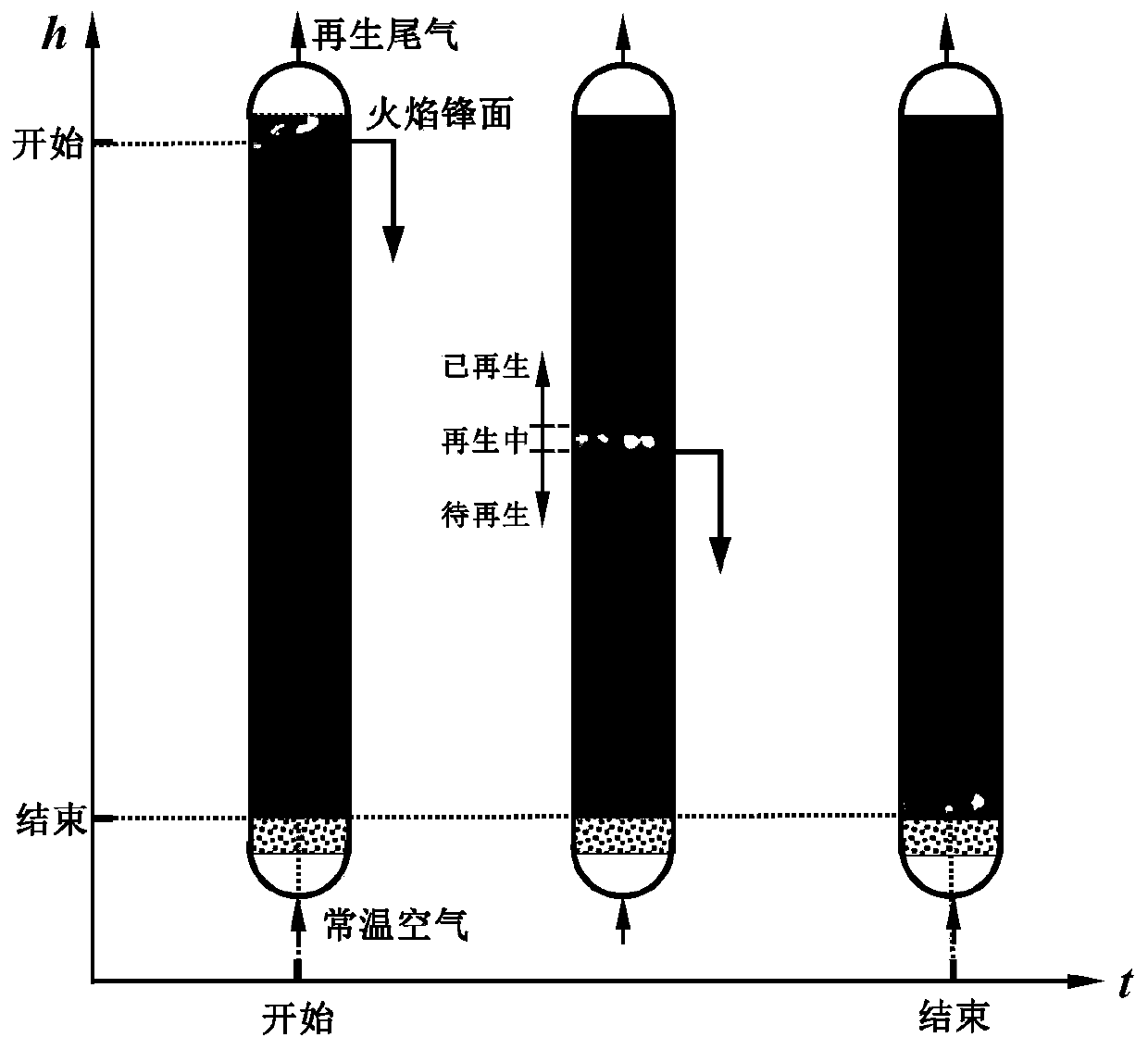

[0076] In embodiment one, as attached figure 1 As shown, a waste activated carbon regeneration device based on self-sustaining combustion is provided, and the device includes an oxidant pipeline connected to the industrial waste gas input end of a conventional activated carbon adsorption bed, and an ignition device electric heating wire is arranged on the output end side, and the waste activated carbon regeneration device Arrange thermocouple sensors and observation windows along the flow direction of the oxidant, and install an air distribution plate on the side of the input end; based on this device, a waste activated carbon (activated carbon particle size of 10-24 mesh) saturated with ethanol was burned through regeneration experiments. During regeneration, the superficial flow velocity of normal temperature air passing into the spent activated carbon bed is 0.065m / s. In order to investigate the effectiveness of the through-type combustion regeneration method, an adsorptio...

Embodiment 2

[0086] In embodiment two, the waste activated carbon used is the same as that in embodiment one, that is, the saturated waste activated carbon (10-24 mesh) that has adsorbed ethanol. At this time, the superficial flow velocity of the air in the regeneration process is controlled to be 0.033m / s. In combination with Example 1 and Example 2, the effect of air flow on the regeneration effect of waste activated carbon adsorbing ethanol will be investigated. The data of the waste activated carbon after four regeneration-adsorption cycle experiments are shown in Table 2.

[0087] It can be seen from Table 2 that after reducing the regeneration air flow rate to 0.033m / s, the adsorption performance of regenerated activated carbon on ethanol is slightly reduced, which is mainly manifested in the reduction of adsorption capacity. However, compared with fresh activated carbon, the reduction rate of activated carbon's adsorption capacity for ethanol after four regenerations was less than ...

Embodiment 3

[0091] In Example 3, a regeneration experiment of penetrating combustion was carried out on another kind of saturated waste activated carbon (the particle size of the activated carbon is 4-6 meshes) that had adsorbed ethanol. At this time, the superficial flow velocity of the air in the regeneration process is controlled to be 0.065m / s. In conjunction with Example 1, this example will examine the applicability of the regeneration method to different activated carbons. The data of the waste activated carbon after five regeneration-adsorption cycle experiments are shown in Table 3.

[0092] For the waste activated carbon, the through-type combustion can still realize its high-efficiency regeneration: 1) The adsorption capacity and adsorption rate of the activated carbon after regeneration are improved, and it is still better than that of fresh activated carbon after five regenerations; 2) After five regenerations, the activated carbon average The single loss rate is 4.56%, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption rate | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com