Titanium dioxide catalyst loaded with tannic acid nickel iron, catalytic system, and preparation method and applications thereof

A technology of titanium dioxide and catalytic system, which is applied in the field of titanium dioxide photocatalytic composite materials loaded with ferronickel tannate and its preparation, can solve the problems of low overpotential, achieve accelerated transfer and transmission, good oxygen production performance, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1, cut the conductive glass to 1×3cm 2 After that, the conductive glass was soaked in acetone solution and water in turn and ultrasonicated for 15 minutes.

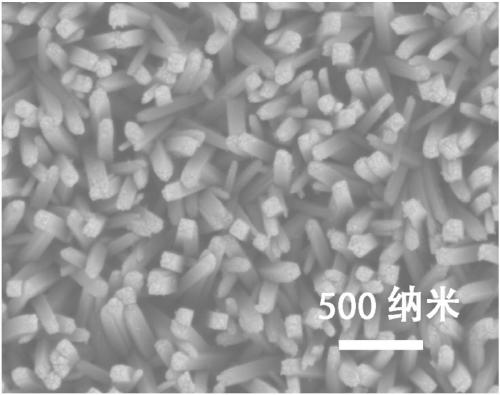

[0043] Step 2, mix 15mL of water, 15mL of concentrated hydrochloric acid and 0.5mL of tetrabutyl titanate in a stainless steel hydrothermal kettle, and stir for 15 minutes. Then take one of the treated glass sheets in step 1 and put it into a hydrothermal kettle with the conductive side facing down, then seal the hydrothermal kettle and react at a temperature of 180° C. for 1 hour.

[0044] Step 3, after the temperature of the hydrothermal kettle in step 2 is cooled, clean the conductive glass with white product on the surface with water and alcohol respectively, and let it air dry naturally.

[0045] Step 4, calcining the conductive glass whose surface is a white product obtained in step 3 in the air at 500° C. for 2 hours to obtain a conductive glass sheet whose surface is a white titanium dioxide product.

...

Embodiment 2

[0049] Step 1, cut the conductive glass to 1×3cm 2 After that, the conductive glass was soaked in acetone solution and water in turn and ultrasonicated for 15 minutes.

[0050] Step 2, mix 15mL of water, 15mL of concentrated hydrochloric acid and 1mL of tetrabutyl titanate in a stainless steel hydrothermal kettle, and stir for 15 minutes. Then take one of the treated glass sheets in step 1 and put it into a hydrothermal kettle with the conductive side facing down, then seal the hydrothermal kettle and react at a temperature of 180° C. for 1 hour.

[0051] Step 3, after the temperature of the hydrothermal kettle in step 2 is cooled, clean the conductive glass with white product on the surface with water and alcohol respectively, and let it air dry naturally.

[0052] Step 4, calcining the conductive glass whose surface is a white product obtained in step 3 in the air at 500° C. for 2 hours to obtain a conductive glass sheet whose surface is a white titanium dioxide product.

...

Embodiment 3

[0056] Step 1, cut the conductive glass to 1×3cm 2 After that, the conductive glass was soaked in acetone solution and water in turn and ultrasonicated for 15 minutes.

[0057] Step 2, mix 15mL of water, 15mL of concentrated hydrochloric acid and 0.5mL of tetrabutyl titanate in a stainless steel hydrothermal kettle, and stir for 15 minutes. Then take one of the treated glass sheets in step 1 and put it into a hydrothermal kettle with the conductive side facing down, then seal the hydrothermal kettle and react at a temperature of 180° C. for 1 hour.

[0058] Step 3, after the temperature of the hydrothermal kettle in step 2 is cooled, clean the conductive glass with white product on the surface with water and alcohol respectively, and let it air dry naturally.

[0059] Step 4, calcining the conductive glass whose surface is a white product obtained in step 3 in the air at 500° C. for 2 hours to obtain a conductive glass sheet whose surface is a white titanium dioxide product. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com