Non-wrinkle graphene and preparation method thereof

A wrinkle-free, graphene-free technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of resistivity, complexity, and high requirements for experimental conditions, and achieve the effect of less defects and thin lamellae.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

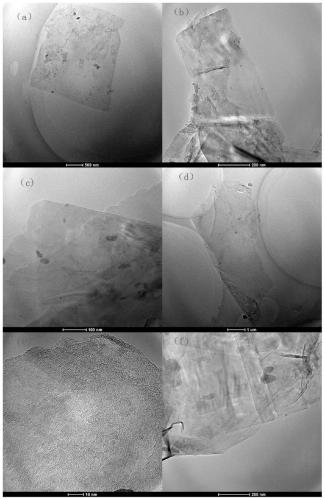

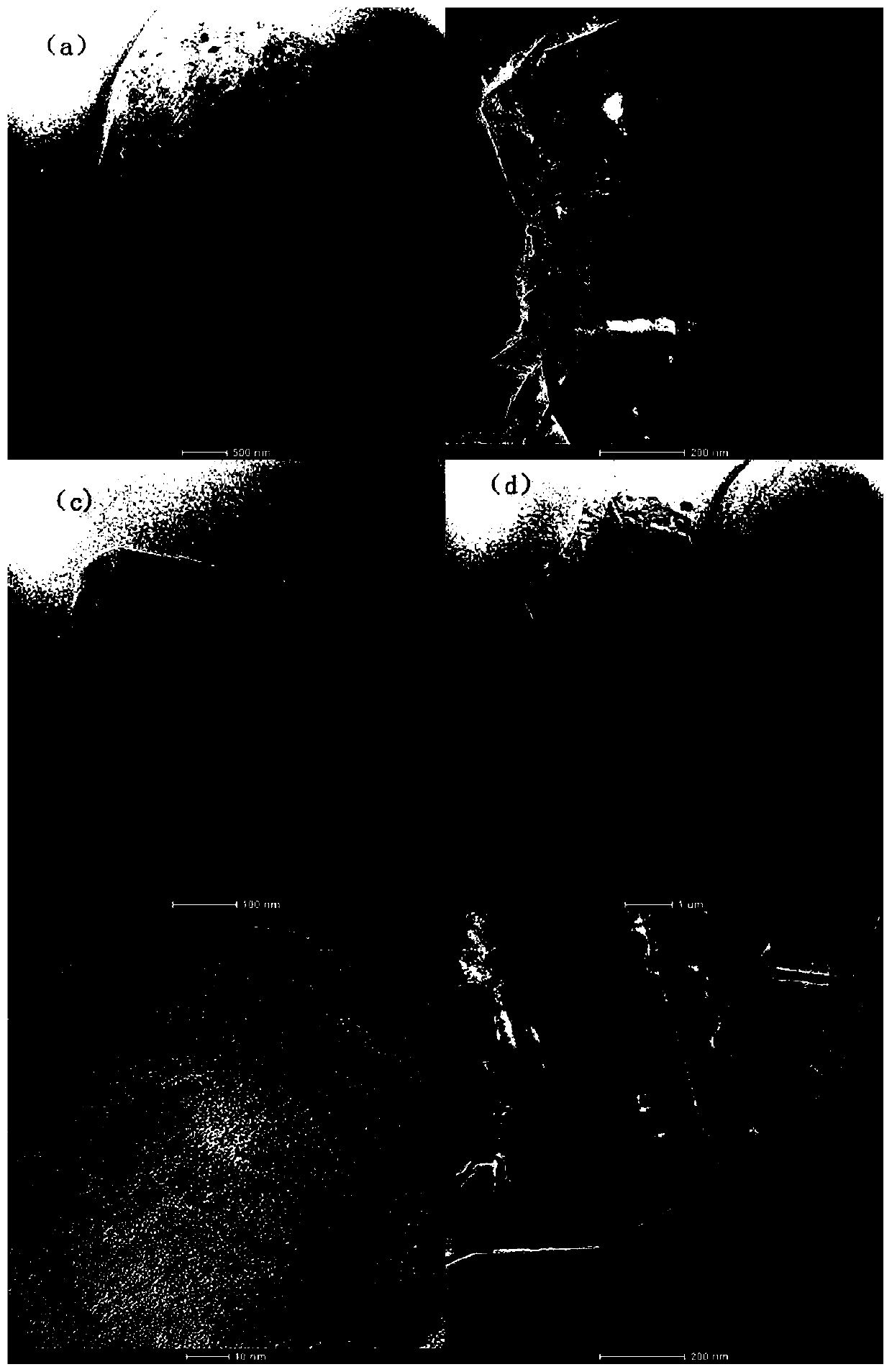

Image

Examples

Embodiment 1

[0021] The wrinkle-free graphene in this embodiment is composed of single-layer or multi-layer graphene structural units, and there is no wrinkle on the surface of the single-layer or multi-layer graphene, and the number of layers is no more than 20.

[0022] A kind of preparation method of above-mentioned wrinkle-free graphene, comprises the steps:

[0023] Disperse 2g of graphite and 2g of sodium chloride in 2ml (2g) of acetophenone solution, place in a reaction kettle, react at 180°C for 20h, cool to room temperature to obtain a graphene dispersion; transfer the graphene dispersion to a centrifuge tube After standing for 3 hours, remove the supernatant, collect 1.9g of precipitate, disperse the precipitate in 91ml of dilute hydrochloric acid (95g) with a concentration of 10wt.%, centrifuge for 20min at a speed of 1500rpm, remove the supernatant, and complete the first time For pickling, add 69.3ml of dilute hydrochloric acid (72.8g) with a concentration of 10wt.% to the 1.8...

Embodiment 2

[0025] The wrinkle-free graphene in this embodiment is composed of single-layer or multi-layer graphene structural units, and there is no wrinkle on the surface of the single-layer or multi-layer graphene, and the number of layers is no more than 20.

[0026] A kind of preparation method of above-mentioned wrinkle-free graphene, comprises the steps:

[0027] Disperse 2g of graphite and 100g of potassium chloride in 127ml (100g) of acetone solution, place in a reaction kettle, react at 200°C for 15h, cool to room temperature to obtain a graphene dispersion; move the graphene dispersion to a centrifuge tube, and After standing for 3 hours, remove the supernatant, collect 1.9g of precipitate, disperse the precipitate in 91ml of 10wt.% dilute hydrochloric acid (95g), centrifuge at 500rpm for 50min, remove the supernatant, and complete the first pickling In the 1.8g precipitate collected after the first pickling, add 51ml of dilute hydrochloric acid (54g) with a concentration of 10...

Embodiment 3

[0029] The wrinkle-free graphene in this embodiment is composed of single-layer or multi-layer graphene structural units, and there are no wrinkles on the surface of the single-layer or multi-layer graphene, and the number of layers is no more than 20.

[0030] A kind of preparation method of above-mentioned wrinkle-free graphene, comprises the steps:

[0031]Disperse 2g of graphite and 100g of magnesium sulfate in 211ml (200g) of cyclopentanone solution, place in a reaction kettle, react at 220°C for 10h, cool to room temperature to obtain a graphene dispersion; move the graphene dispersion to a centrifuge tube, After standing for 3 hours, remove the supernatant, collect 1.9g of precipitate, disperse the precipitate in 91ml of 10wt.% dilute hydrochloric acid (95g), centrifuge at 1000rpm for 30min, remove the supernatant, and complete the first acid Washing, in the 1.82g precipitate that will be collected after finishing the 1st pickling, add the dilute hydrochloric acid (81.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com