A kind of AGME contact material for circuit breaker and preparation method thereof

A technology for contact materials and circuit breakers, which is applied to circuits, contacts, metal processing equipment, etc., can solve the problems of cumbersome preparation process, complex process, and high requirements for production environment equipment, so as to improve the density of the green body and reduce the internal pressure of the barrel. Effect of temperature, good arc resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

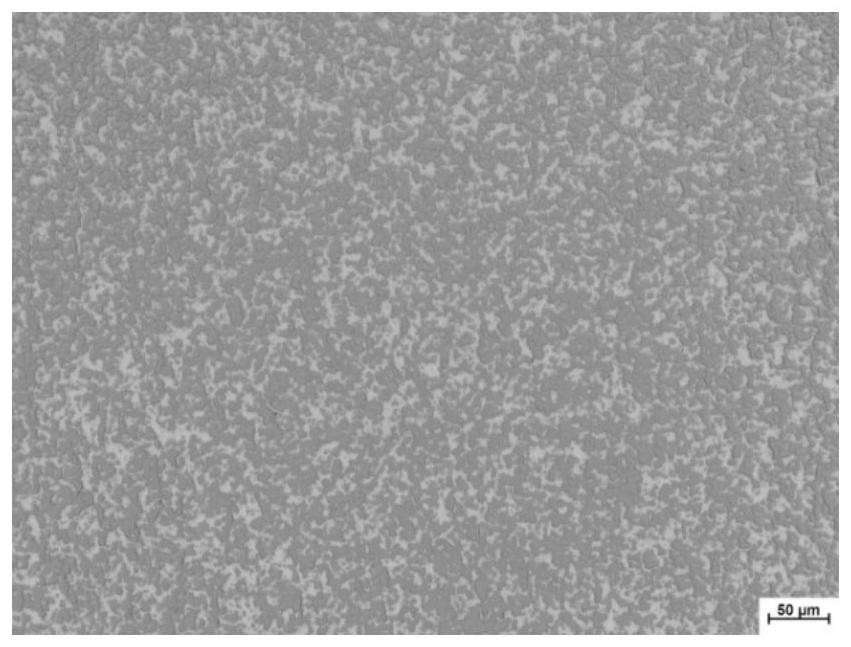

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing an AgMe contact material for a circuit breaker, comprising the following steps:

[0038] In the first step, first put 65wt% of W powder, 1wt% of Ni powder, and 34wt% of silver powder in a powder mixer for premixing at a speed of 40 rpm for 1 hour and pass through a 100-mesh sieve.

[0039] In the second step, the mixed powder obtained in the first step is ball milled, the ball milling speed is 60 rpm and 150 rpm, the alternating time is 0.5h, and the ball milling time is 5 hours, adding balls and deionized water, The ball-to-water ratio (that is, the weight ratio of grinding balls, powder, and deionized water) is 2:1:0.25.

[0040]In the third step, the powder after wet ball milling is wet-mixed and granulated, and PVA glue is added. The glue-mixing temperature is 90°C, the amount of glue added is 10% of the weight of the powder, and the drying temperature is 100°C.

[0041] In the fourth step, the rubber-mixed and granul...

Embodiment 2

[0047] This embodiment provides a method for preparing an AgMe contact material for a circuit breaker, comprising the following steps:

[0048] In the first step, first put 50wt% of WC powder, 1.5% of Fe powder, 1wt% of Co powder, 0.5% of Cu powder, and 48wt% of silver powder in a powder mixer for pre-mixing at a speed of 30 rpm for 4 hours , through a 200-mesh sieve.

[0049] In the second step, the mixed powder obtained in the first step is subjected to ball milling, the ball milling speed is 100 rpm and 250 rpm, the alternating time is 1 h, and the ball milling time is 8 hours, adding grinding balls and absolute ethanol, ball milling The ratio of material to ethanol (that is, the weight ratio of grinding balls, powder, and absolute ethanol) is 1:1:0.1.

[0050] In the third step, the powder after wet ball milling is wet-mixed and granulated, and PVP glue is added. The glue-mixing temperature is 75°C, the amount of glue added is 15% of the weight of the powder, and the dryi...

Embodiment 3

[0057] This embodiment provides a method for preparing an AgMe contact material for a circuit breaker, comprising the following steps:

[0058] In the first step, at first 68.5wt% of W powder, 1.0wt% of Ni powder, 0.5wt% of Cu powder, and 30wt% of silver powder are placed in a powder mixer for premixing, and the rotating speed is 20 rpm for 6 hours. 400 mesh sieve.

[0059] In the second step, the mixed powder obtained in the first step is ball milled, the ball milling speed is 300 rpm and 60 rpm, the alternating time is 0.5h, the ball milling time is 24 hours, adding grinding balls and acetone, the ball material The acetone ratio (that is, the weight ratio of grinding balls, powder, and acetone) is 3:1:0.6.

[0060] In the third step, the powder after wet ball milling is wet-mixed and granulated, and PEG glue is added. The glue-mixing temperature is 100°C, the amount of glue added is 20% of the weight of the powder, and the drying temperature is 110°C.

[0061] In the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com