A kind of preparation method of all-vanadium redox flow battery diaphragm

An all-vanadium redox flow battery and diaphragm technology, applied in the field of ion exchange membrane, can solve the problems of high vanadium permeability and high price of vanadium redox flow battery diaphragm, achieve good thermal stability, ensure proton conductivity, and be easy to process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

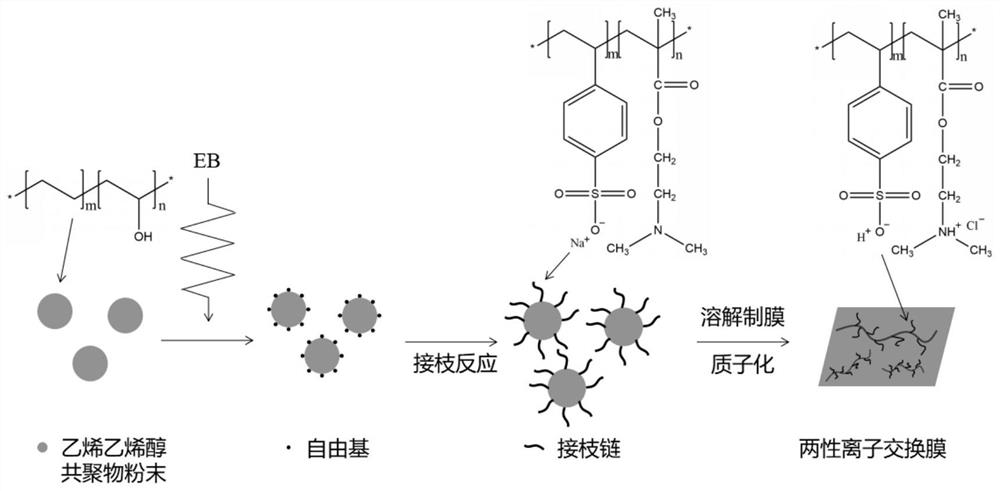

[0029] A kind of preparation method of all-vanadium redox flow battery separator provided by the present invention comprises the following steps:

[0030] (1) The ethylene-vinyl alcohol copolymer powder is irradiated and grafted with γ-rays or electron beams, and the free radicals generated after the surface of the ethylene-vinyl alcohol copolymer powder is irradiated react with grafting monomers After the reaction is completed, take out the powder after irradiation and grafting, and clean and remove unreacted monomers;

[0031] Wherein, the reaction monomer comprises sodium styrene sulfonate and dimethylaminoethyl methacrylate;

[0032] (2) converting the copolymer powder after irradiation and grafting in step (1) into a membrane material, and then performing a protonation reaction on the membrane material to obtain an all-vanadium redox flow battery diaphragm.

[0033] In some embodiments, the particle size of the ethylene-vinyl alcohol copolymer powder is between 60 mesh a...

Embodiment 1

[0052] A low-cost all-vanadium redox flow battery membrane, i.e., the preparation method of the amphoteric ion exchange membrane is as follows:

[0053] 20g of ethylene-vinyl alcohol copolymer (the content of polyethylene in the ethylene-vinyl alcohol copolymer is 44%) powder is packed into a polyethylene bag and paved, and vacuum-sealed, placed on a dolly equipped with dry ice, passed The pre-irradiation is carried out under the accelerator beam, and the absorbed dose is 120kGy, and then the irradiated ethylene vinyl alcohol copolymer powder is cooled and stored in dry ice for later use.

[0054] In a 500mL three-necked flask, add 11.2g dimethylaminoethyl methacrylate, 48.8g sodium styrene sulfonate and 200g water (the molar ratio of dimethylaminoethyl methacrylate to sodium styrene sulfonate is 0.3:1, single The total body concentration is 30%). Stir well under the protection of nitrogen and raise the temperature to 70°C, add the irradiated ethylene vinyl alcohol copolymer ...

Embodiment 2

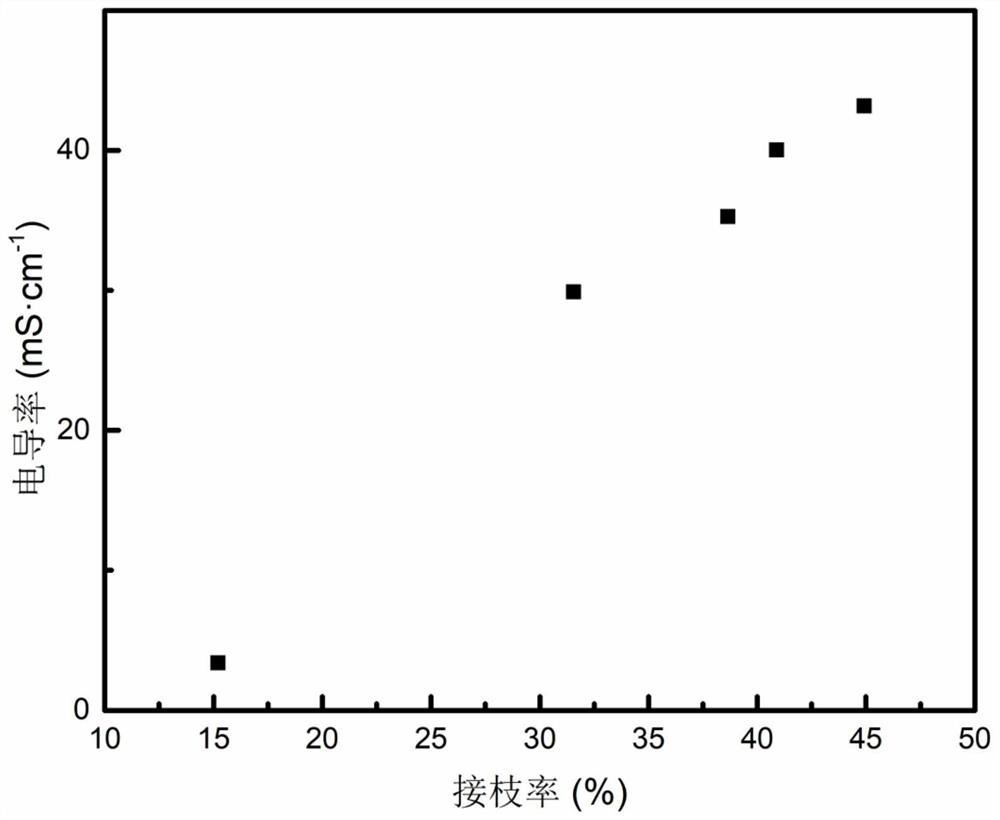

[0059] The conductivity test of the ion-exchange membrane that embodiment 1 makes

[0060] Place the amphoteric ion-exchange membrane obtained in Example 1 in 1M sulfuric acid to activate for 6h, dry its surface water with filter paper, sandwich it between two stainless steel electrodes, test its AC impedance curve through an electrochemical workstation, and calculate Its conductivity is 40.01 mS / cm.

[0061] figure 2 It is a graph showing the relationship between the electrical conductivity and the grafting rate of the vanadium redox flow battery diaphragm prepared in the present invention. It can be seen that the electrical conductivity of the diaphragm increases with the increase of the grafting rate. However, when the grafting rate is too high, the grafted powder cannot be dissolved to form a film, so it is necessary to select a powder with a suitable grafting rate to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com