A kind of catalyst for preparing m-toluic acid and its preparation method and application

A technology of methyl benzoic acid and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of high impurities, increased solid waste, and unfriendly environment and other issues, to achieve good selectivity, reduce impurities, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

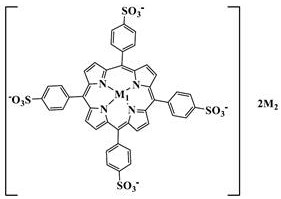

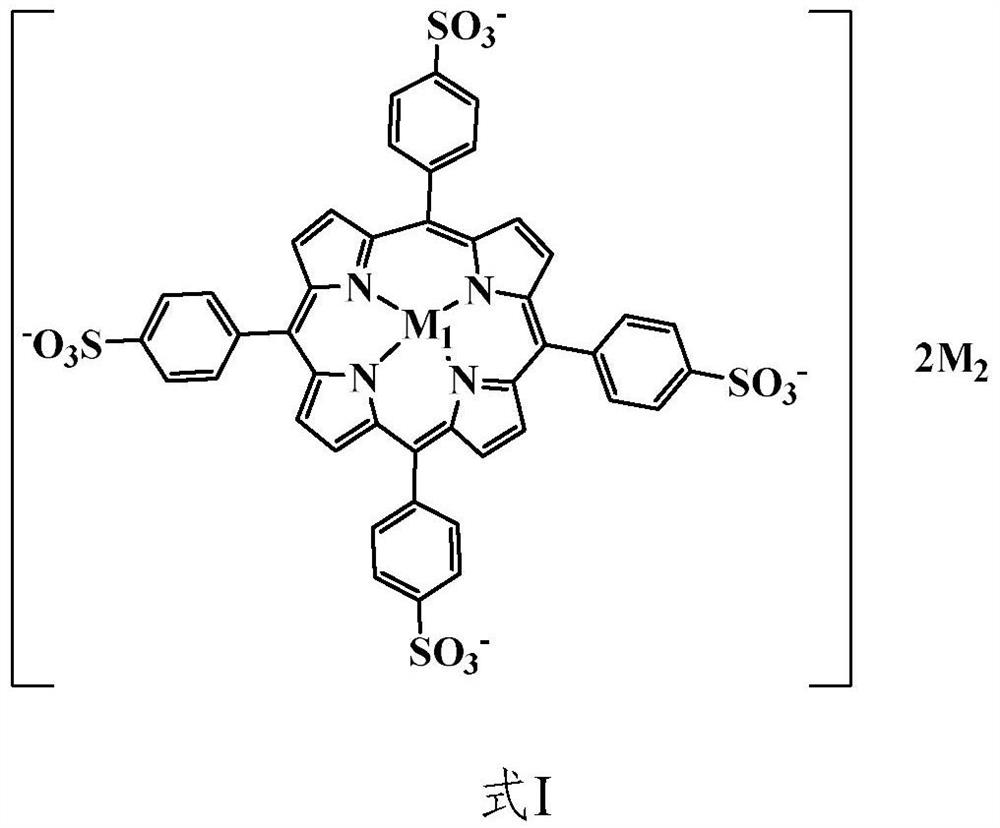

[0038] Under the protection of nitrogen, add deionized water (26kg), porphyrin tetrasulfonic acid (9.35kg), and cobalt acetate (1.77kg) to a 50L glass reactor in sequence, react at 60°C for 2 hours, and distill off the water under reduced pressure and acetic acid, the resulting solid was recrystallized from aqueous methanol to give cobalt porphyrin sulfonic acid. Under nitrogen protection, deionized water (25kg) and recrystallized cobalt porphyrin sulfonic acid were successively added to a 50L glass reactor, and at 15°C, manganese hydroxide (1.78kg) ultrafine powder was slowly added in batches, and stirred for 6 hour, then warming up to reflux reaction for 6 hours, steaming water under reduced pressure, and drying the solid in vacuum to obtain cobalt porphyrin manganese sulfonate (i.e. M in formula I 1 for Co, M 2 For Mn) catalyst.

[0039] Pour m-xylene and manganese cobalt porphyrin sulfonate into the material mixer. The ratio of the above materials is 1:15ppm respectively...

Embodiment 2

[0042] Under nitrogen protection, deionized water (26kg), porphyrin tetrasulfonic acid (9.35kg), and manganese acetate (1.73kg) were successively added to a 50L glass reactor, reacted at 60°C for 2 hours, and evaporated under reduced pressure to remove water and acetic acid, the resulting solid was recrystallized from aqueous methanol to give cobalt porphyrin sulfonic acid. Under nitrogen protection, deionized water (25kg) and recrystallized manganese porphyrin sulfonic acid were successively added to a 50L glass reactor, and at 15°C, cobalt hydroxide (1.86kg) ultrafine powder was slowly added in batches, and stirred for 6 hour, then raise the temperature and reflux reaction for 6 hours, steam off the water under reduced pressure, and the gained solid is vacuum-dried to obtain the cobalt manganese porphyrin sulfonate catalyst (i.e. M in the formula I 1 for Mn, M 2 for Co).

[0043]Pour m-xylene and cobalt manganese porphyrin sulfonate into the material mixer. The ratio of th...

Embodiment 3

[0046] Under nitrogen protection, deionized water (26kg), porphyrin tetrasulfonic acid (9.35kg), and manganese acetate (1.73kg) were successively added to a 50L glass reactor, reacted at 60°C for 2 hours, and evaporated under reduced pressure to remove water and acetic acid, the resulting solid was recrystallized from aqueous methanol to give cobalt porphyrin sulfonic acid. Under nitrogen protection, deionized water (25kg) and recrystallized manganese porphyrin sulfonic acid were successively added to a 50L glass reactor, and at 15°C, manganese hydroxide (1.78kg) ultrafine powder was slowly added in batches, and stirred for 6 hour, then warming up and reflux reaction for 6 hours, steamed water under reduced pressure, and the gained solid was vacuum-dried to obtain manganese porphyrin sulfonate manganese catalyst (i.e. M in formula I 1 , M 2 are both Mn).

[0047] Pour m-xylene and manganese manganese porphyrin sulfonate into the material mixer. The ratio of the above materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com