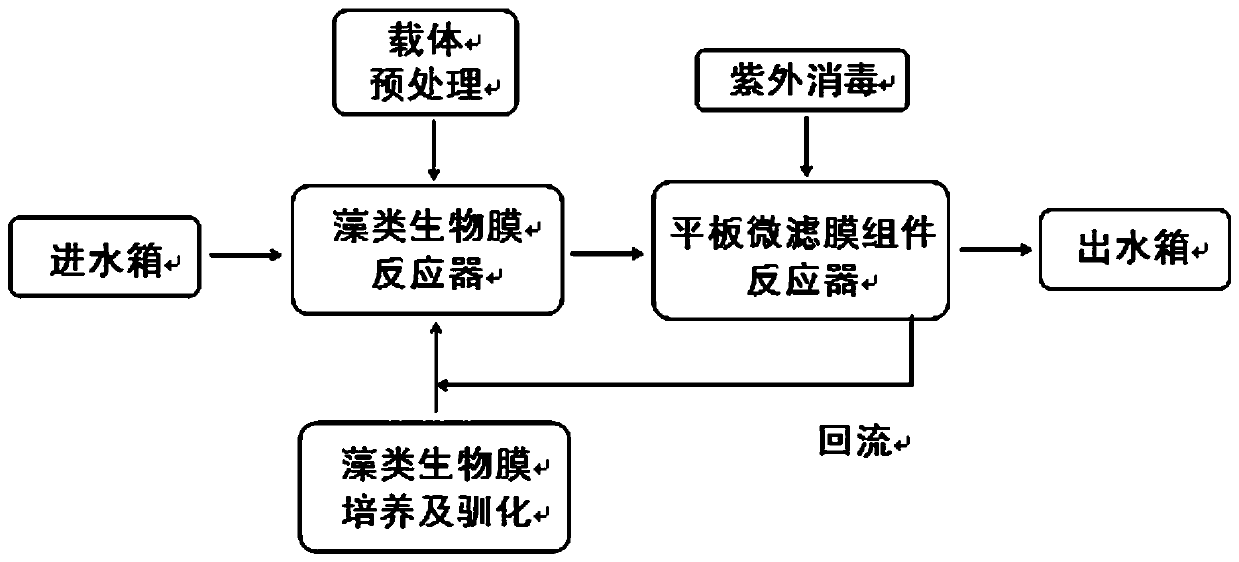

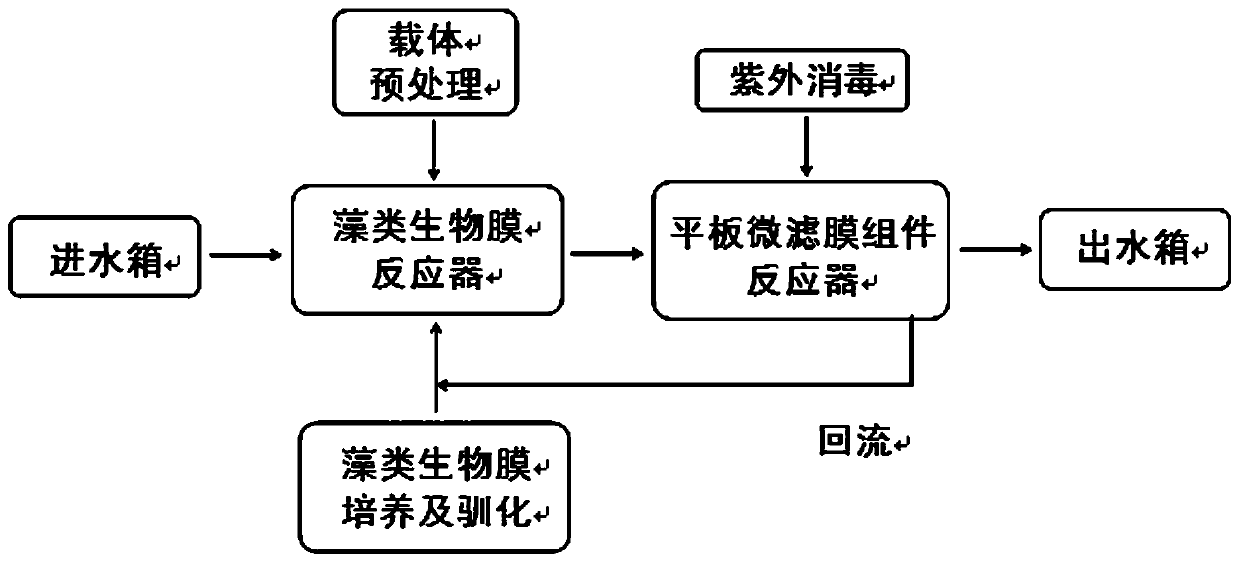

Method for treating sewage by double-membrane system of algae bio-membrane and plate micro-filtration membrane

A technology of algal biofilm and microfiltration membrane, which is applied in biological water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. It can reduce the impact of chemical change and the effect is difficult to improve again, so as to achieve the effect of saving material consumption, improving service life and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for treating sewage by using an algae membrane and a flat microfiltration membrane dual-membrane system. While using algae biofilm for sewage treatment, a flat microfiltration membrane module is added for secondary treatment, which improves the recycling rate of algae biofilm. At the same time, the water quality of the effluent is also improved; the specific steps are as follows:

[0025] (1) Pretreatment of the elastic three-dimensional carrier: soak the elastic three-dimensional carrier in 1.0mol / L NaHCO 3 In the solution, soaking time: 24 hours, then rinse 4 times with deionized water, soak the obtained biofilm carrier in hydrochloric acid with a concentration of 1.0 mg / L for 12.5 hours, rinse 4 times with deionized water and dry.

[0026] (2) Preparation of algae biofilm: add BG11 medium and pretreated elastic three-dimensional carrier into the bioreactor, the volume of the medium is 8L, inoculate the algae liquid into the medium, the volume of the algae li...

Embodiment 2

[0035] A method for treating sewage by using an algae membrane and a flat microfiltration membrane dual-membrane system. While using algae biofilm for sewage treatment, a flat microfiltration membrane module is added for secondary treatment, which improves the recycling rate of algae biofilm. At the same time, the water quality of the effluent is also improved; the specific steps are as follows:

[0036] (1) Pretreatment of the elastic three-dimensional carrier: soak the elastic three-dimensional carrier in 0.05mol / L NaHCO 3 In the solution, soaking time: 23 hours, then rinse 3 times with deionized water, soak the obtained biofilm carrier in hydrochloric acid with a concentration of 0.05mg / L for 11 hours, rinse 3 times with deionized water and dry in the air.

[0037] (2) Preparation of algae biofilm: Add BG11 medium and pretreated elastic three-dimensional carrier into the bioreactor, the volume of the medium is 8L, inoculate the algae liquid into the medium, the volume of th...

Embodiment 3

[0046] A method for treating sewage by using an algae membrane and a flat microfiltration membrane dual-membrane system. While using algae biofilm for sewage treatment, a flat microfiltration membrane module is added for secondary treatment, which improves the recycling rate of algae biofilm. At the same time, the water quality of the effluent is also improved; the specific steps are as follows:

[0047] (1) Pretreatment of the elastic three-dimensional carrier: soak the elastic three-dimensional carrier in 1.5mol / L NaHCO 3 In the solution, soaking time: 23 hours, then rinse 3 times with deionized water, soak the obtained biofilm carrier in hydrochloric acid with a concentration of 2.0mg / L for 11 hours, rinse 3 times with deionized water and dry.

[0048] (2) Preparation of algae biofilm: add BG11 medium and pretreated elastic three-dimensional carrier into the bioreactor, the volume of the medium is 8L, inoculate the algae liquid into the medium, the volume of the algae liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com