Method for synthesizing polymeric microspheres

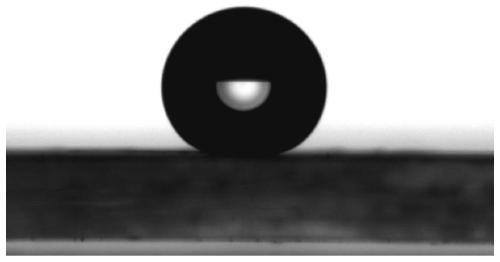

A technology for synthesizing polymers and polymer solutions, applied in the field of polymer microsphere preparation, can solve the problems of difficult size control, low reaction efficiency, back-locking of synthesis process steps, etc., achieves good molding state, simple preparation process, and is conducive to popularization applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for synthesizing polymer microspheres in this embodiment comprises the following steps:

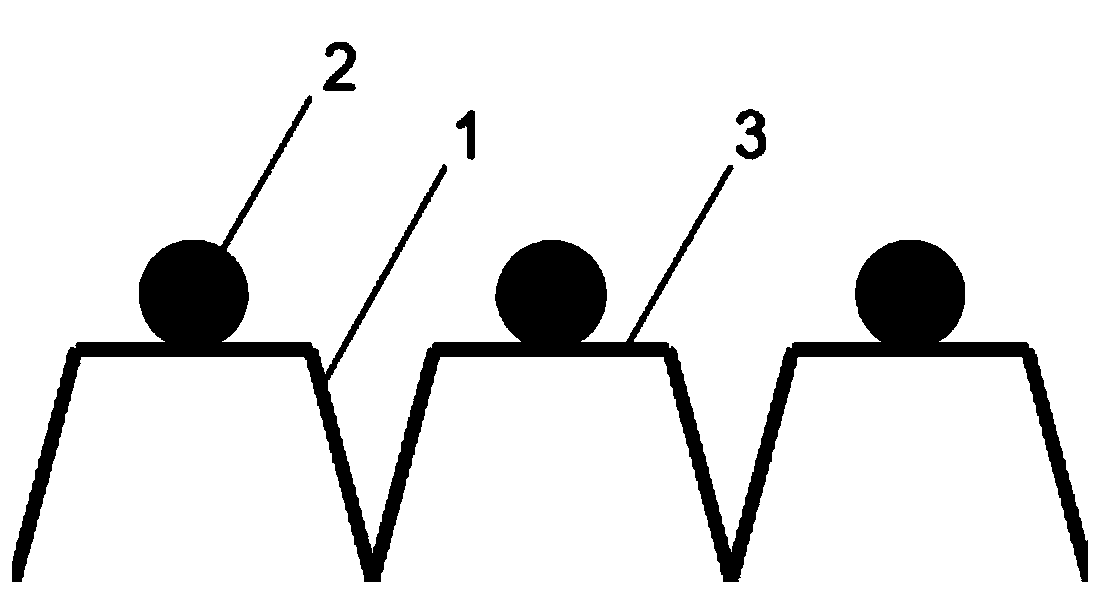

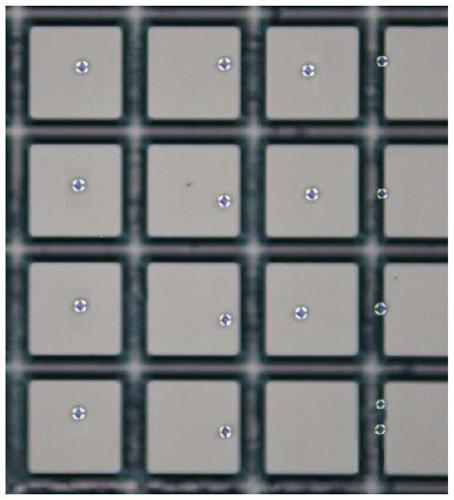

[0039] (1) Photolithography on the surface of the silicon wafer to obtain a microstructure with grooves and micro-platforms.

[0040] The silicon wafer was treated with plasma under vacuum condition for 25 minutes, and then the silicon wafer was heated at 300° C. for 25 minutes. Under the condition of yellow light irradiation, the photoresist is dropped on the surface of the silicon wafer with a thickness of 500um, an oxide layer thickness of 300nm, a crystal orientation of 100° and a diameter of 100mm, and then spin-coated, and the spin-coating acceleration is 750r / s 2 , the maximum speed is 3500r / s, then the silicon wafer is heated and solidified at 100°C, then the mask plate is exposed for 6s, and developed for 20s with a developer; the developer is 20wt% tetramethylammonium hydroxide solution and water according to 1: 7 volume ratio configuration.

[0041] The sili...

Embodiment 2

[0046] The method for synthesizing polymer microspheres in this embodiment comprises the following steps:

[0047] (1) Photolithography on the surface of the silicon wafer to obtain a microstructure with grooves and micro-platforms.

[0048] The silicon wafer was treated with plasma under vacuum for 35 minutes, and then the silicon wafer was heated at 250° C. for 35 minutes. Under the condition of yellow light irradiation, the photoresist is dropped on the surface of the silicon wafer with a thickness of 600um, an oxide layer thickness of 310nm, a crystal orientation of 100.5° and a diameter of 100.3mm, and then spin-coated, and the spin-coating acceleration is 850r / s 2 , the maximum speed is 3500r / s, then the silicon wafer is heated and solidified at 120°C, then the mask plate is exposed for 7s, and developed for 24s with a developer; the developer is 30wt% tetramethylammonium hydroxide solution and water according to 1: 9 volume ratio configuration.

[0049] The silicon wa...

Embodiment 3

[0054] The method for synthesizing polymer microspheres in this embodiment comprises the following steps:

[0055] (1) Photolithography on the surface of the silicon wafer to obtain a microstructure with grooves and micro-platforms.

[0056] The silicon wafer was treated with plasma under vacuum condition for 30 minutes, and then the silicon wafer was heated at 280° C. for 30 minutes. Under the condition of yellow light irradiation, the photoresist is dropped on the surface of the silicon wafer with a thickness of 400um, an oxide layer thickness of 290nm, a crystal orientation of 99.5° and a diameter of 99.7mm, and then spin-coated, and the spin-coating acceleration is 800r / s 2 , the maximum speed is 3500r / s, then the silicon wafer is heated and solidified at 110°C, then the mask plate is exposed for 7s, and developed for 22s with a developer; the developer is 25wt% tetramethylammonium hydroxide solution and water according to 1: The volume ratio of 8 is configured.

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com