Efficient process for preparing white carbon black from oil shale waste residues

A technology for oil shale waste residue and white carbon black is applied in the field of white carbon black, which can solve the problems of poor performance such as specific surface area of white carbon black, many preparation steps, and high operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

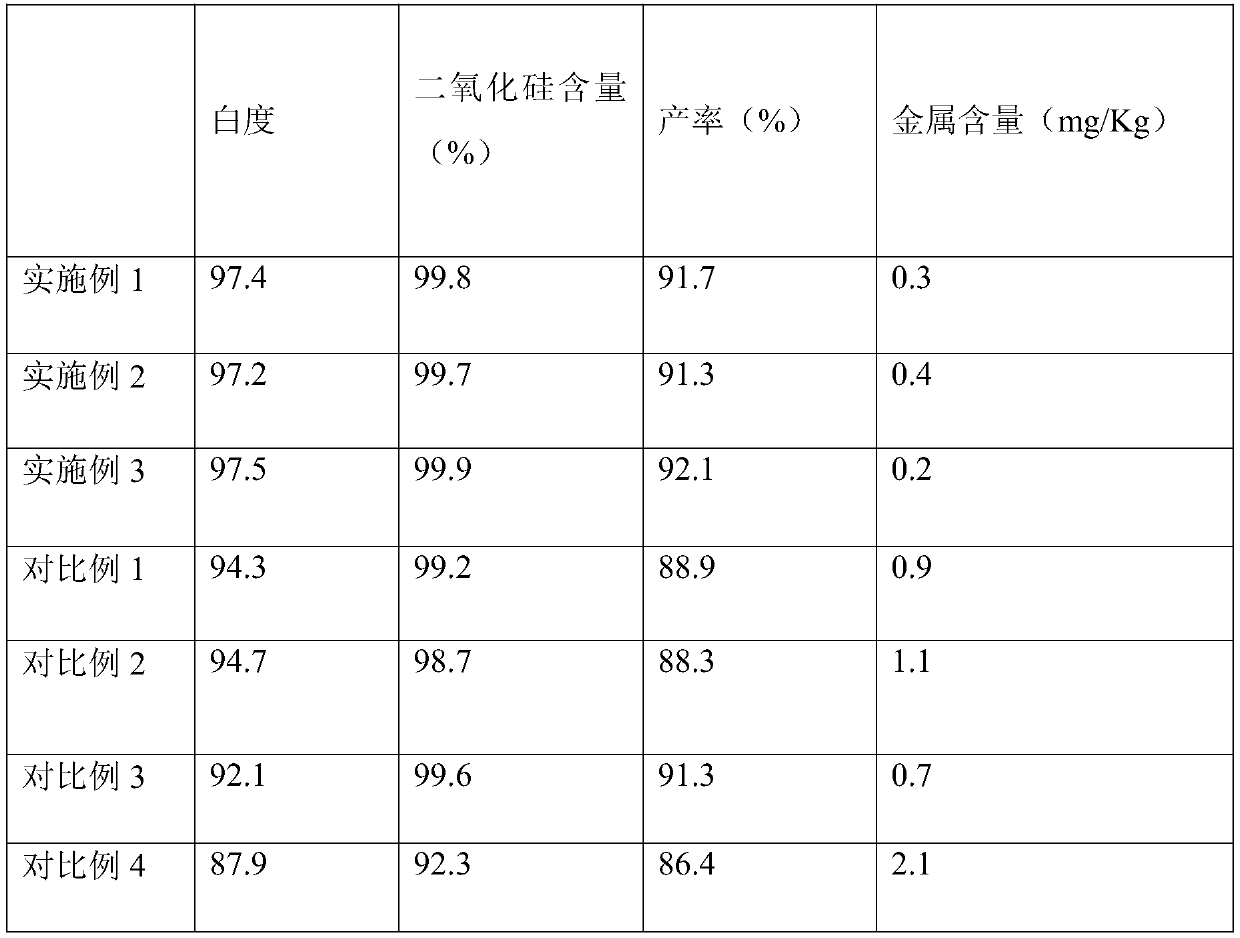

Examples

Embodiment 1

[0025] A kind of high-efficiency process for preparing white carbon black from oil shale waste residue of the present embodiment comprises the following steps:

[0026] Step 1: Put the oil shale waste residue in water and let it stand for 1 hour, then filter it, rinse the filter residue twice with clean water, then dry it in a drying oven until the surface moisture content is 5%, and then send it to a ball mill tank for ball milling until the waste residue The particle size is 20mm, and then sent to the calciner for primary activation treatment, and then mixed with pickling agent according to the weight ratio of 1:3 and sent to the cooking pot for cooking treatment, cooking for 30min, after cooking, filtering, washing, and then Drying, followed by secondary activation treatment to obtain the pre-used material for subsequent use;

[0027] Step 2: Send the spare pre-used materials in Step 1 into the improvement solution for stirring at a stirring speed of 100r / min, stir for 10mi...

Embodiment 2

[0037] A kind of high-efficiency process for preparing white carbon black from oil shale waste residue of the present embodiment comprises the following steps:

[0038] Step 1: Put the oil shale waste residue in water and let it stand for 2 hours, then filter it, rinse the filter residue with clean water for 3 times, then dry it in a drying oven until the surface moisture content is 9%, and then send it to a ball mill tank for ball milling until the waste residue The particle size is 100mm, and then sent to the calciner for primary activation treatment, and then mixed with pickling agent according to the weight ratio of 1:3 and sent to the cooking pot for cooking treatment, cooking for 40min, after cooking, filtering, washing, and then Drying, followed by secondary activation treatment to obtain the pre-used material for subsequent use;

[0039] Step 2: Send the pre-used materials spared in Step 1 into the improvement solution for stirring at a stirring speed of 200r / min, stir...

Embodiment 3

[0049] A kind of high-efficiency process for preparing white carbon black from oil shale waste residue of the present embodiment comprises the following steps:

[0050] Step 1: Put the oil shale waste residue in water and let it stand for 1.5 hours, then filter it, rinse the filter residue with clean water for 3 times, then dry it in a drying oven until the surface moisture content is 7%, and then send it to a ball mill tank for ball milling to The particle size of the waste residue is 60mm, and then sent to the calciner for primary activation treatment, and then mixed with pickling agent according to the weight ratio of 1:3 and sent to the cooking pot for cooking treatment, cooking for 35min, after cooking, filtering, washing, Re-drying, followed by secondary activation treatment to obtain the pre-used material for subsequent use;

[0051] Step 2: Send the pre-used materials spared in Step 1 into the improvement solution for stirring at a stirring speed of 150r / min, stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com