Piebald crystalline glaze and firing method thereof

A crystallized glaze and mottled technology, applied in the field of mottled crystallized glaze and its firing, can solve the problems of undefined size range and shape of macroscopic crystals, achieve various colors, reduce firing difficulty, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

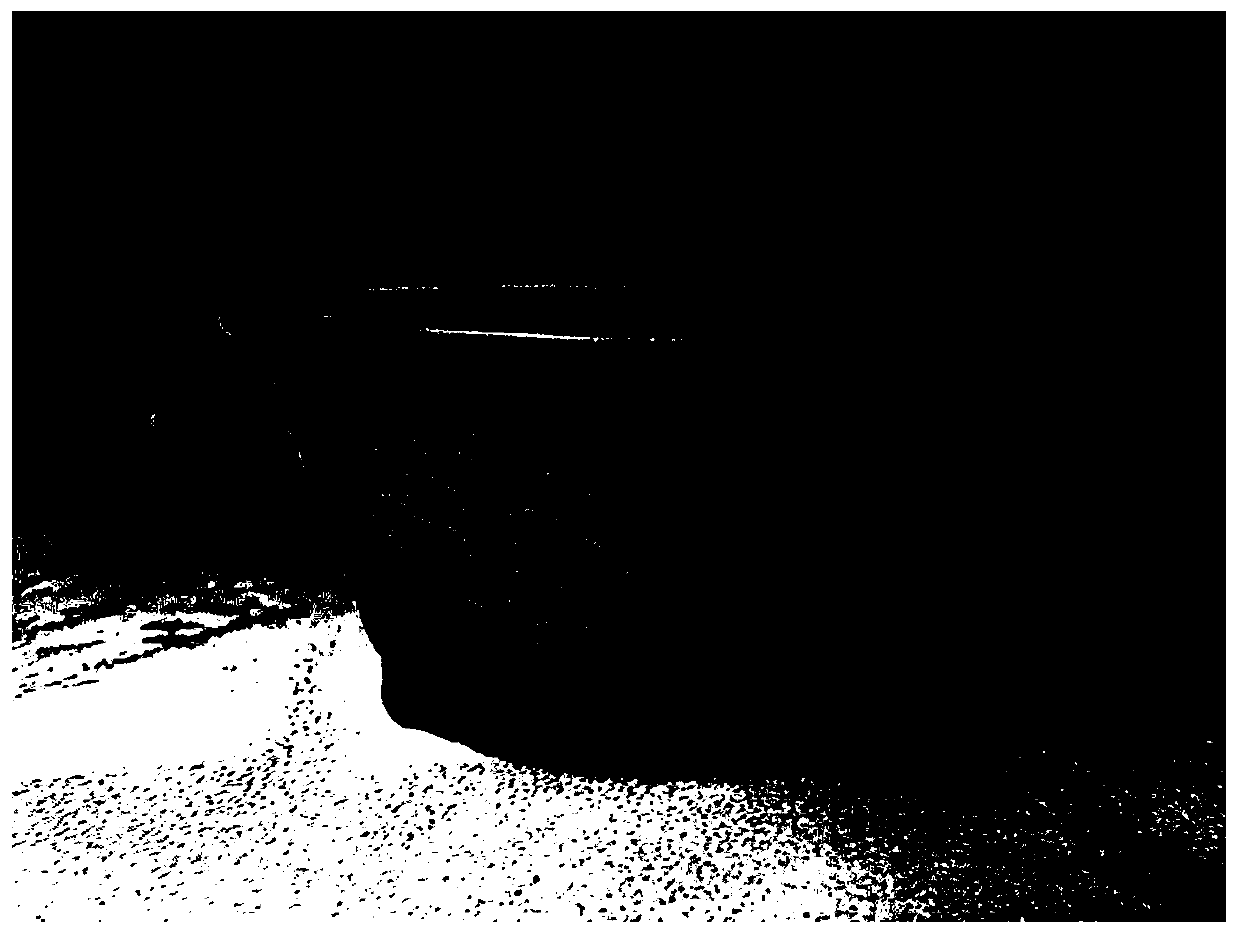

Examples

Embodiment 1

[0051] A mottled crystal glaze only comprises the following components in parts by weight: 20 parts of glass powder, 22 parts of zinc oxide, 50 parts of potassium feldspar, and 7 parts of dolomite. Coloring accelerator: 4 parts of nickelous oxide and copper oxide. Glaze is applied on pottery blanks such as purple sand blanks, and can also be used on white pottery blanks.

[0052] A firing method for piebald crystal glaze, comprising the following steps:

[0053] 1) After the raw materials are weighed according to the formula, all the raw materials except zinc oxide are poured into the ball mill tank, according to the material: ball: water = 1: 1.5: 1.2 and quickly ball milled for 6 minutes;

[0054] 2) Add the weighed zinc oxide to the ball-milled glaze obtained in step 1), and continue ball-milling for 2 minutes;

[0055] 3) pass the glaze obtained in step 2) through an 80-mesh sieve, and set aside;

[0056] 4) Dip or spray glaze on the surface of the product, the thicknes...

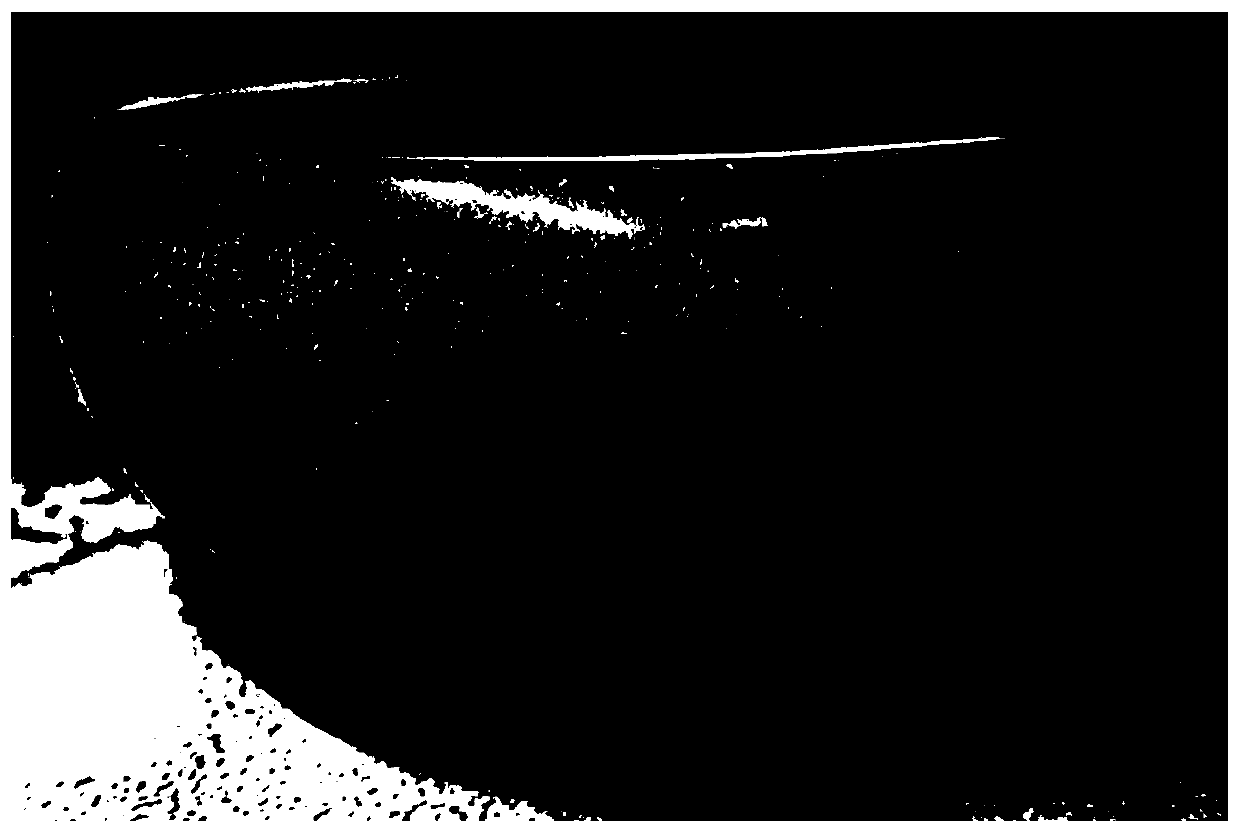

Embodiment 2

[0060] A mottled crystal glaze, which only contains the following components in parts by weight: 30 parts of glass powder, 20 parts of zinc oxide, 41 parts of potassium feldspar, 10 parts of calcite, and a coloring crystal accelerator: 6 parts in total of nickelous oxide and iron oxide . Glaze is applied on white clay clay with low iron content.

[0061] A firing method for piebald crystal glaze, comprising the following steps:

[0062] 1) After the raw materials are weighed according to the formula, all raw materials except zinc oxide are poured into the ball mill tank, according to the material: ball: water = 1: 1.5: 1.0 rapid ball mill for 6 minutes;

[0063] 2) Add the weighed zinc oxide to the ball-milled glaze obtained in step 1), and continue ball-milling for 2 minutes;

[0064] 3) pass the glaze obtained in step 2) through an 80-mesh sieve, and set aside;

[0065] 4) Dip or spray glaze on the surface of the product, the thickness of the glaze layer is 1.0mm;

[006...

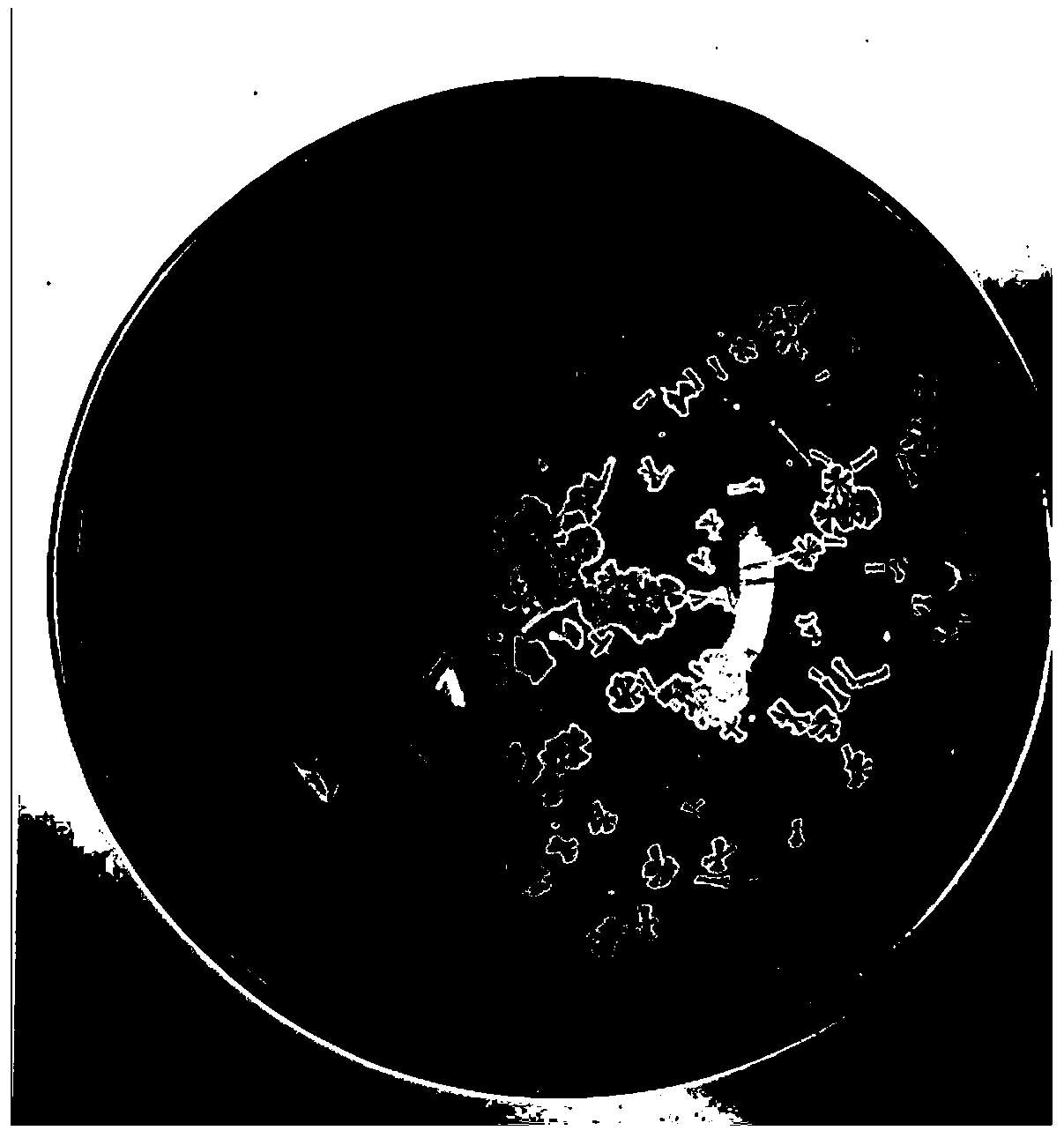

Embodiment 3

[0069] A mottled crystal glaze, which only comprises the following components in parts by weight: 20 parts of glass powder, 25 parts of pure zinc oxide, 50 parts of potassium feldspar, 10 parts of calcite, 2 parts of kaolin and 4 parts of flux. The colored crystal accelerator is 5 parts of nickelous oxide and iron oxide.

[0070] Adding kaolin as an additive is to improve the suspension stability of the glaze, and adding flux is to reduce the viscosity of the high-temperature glaze melt, reduce the crystal growth resistance, and make the surface smoother and more beautiful.

[0071] The flux is any carbonate of lithium, sodium and potassium.

[0072] A firing method for piebald crystal glaze, comprising the following steps:

[0073] 1) After the raw materials are weighed according to the formula, all raw materials except zinc oxide are poured into the ball mill tank, according to the material: ball: water = 1: 1.5: 1.0 rapid ball mill for 6 minutes;

[0074] 2) Add the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com