Method for preparing pollucite glass ceramic by low-temperature liquid phase sintering

A technology of glass-ceramics and low-temperature liquid phase, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high synthesis temperature, corrosion equipment, high-temperature volatilization of Cs, etc., and achieve simple process and equipment, avoid High temperature volatilization and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

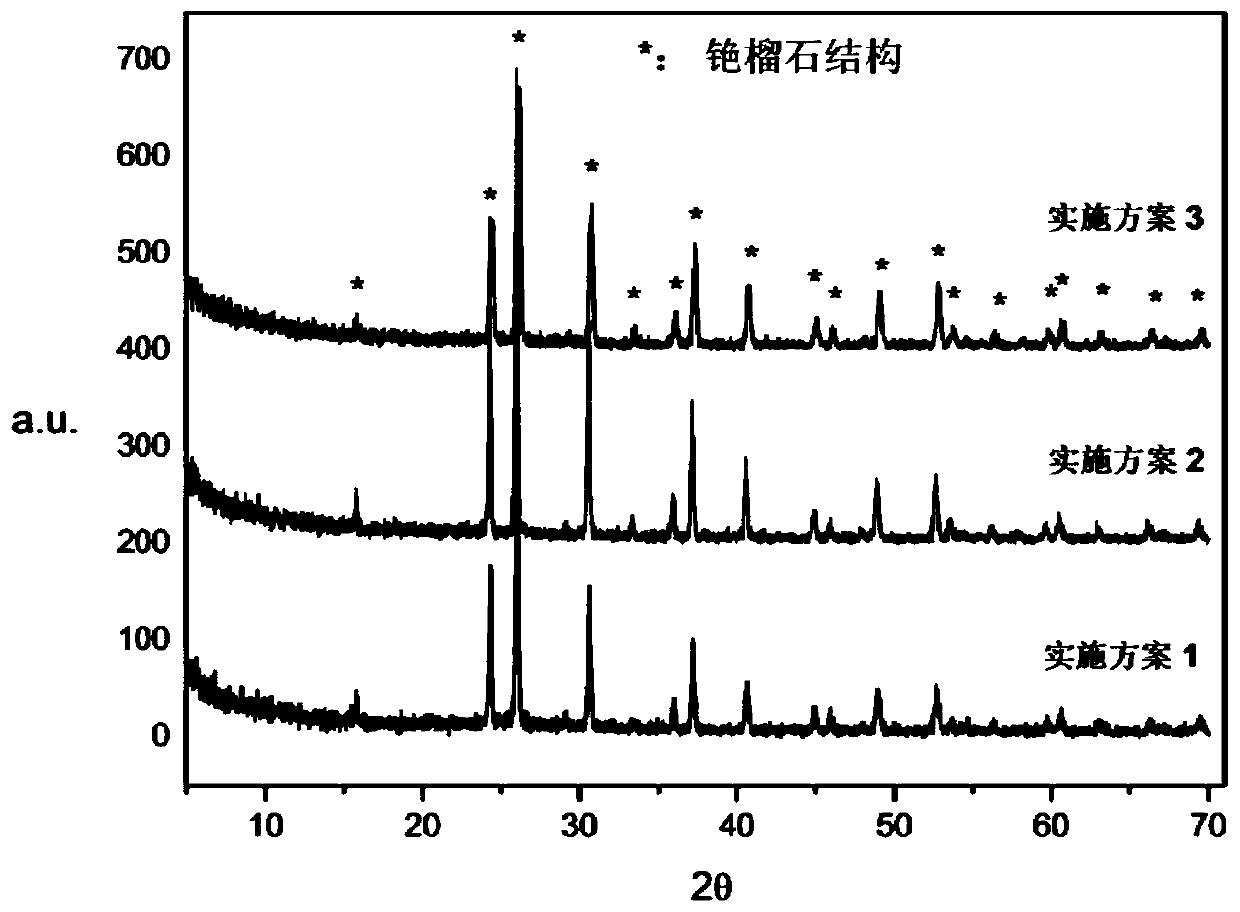

Embodiment 1

[0037] A method for preparing cesium garnet glass-ceramic by low-temperature liquid-phase sintering provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0038] (1) get solid raw material activation kaolin, boric acid, cesium hydroxide monohydrate and sodium hydroxide, according to the molar ratio of chemical element is Cs 0.8 Na 1.2 O·Al 2 o 3 ·5SiO2 2 0.7B 2 o 3 The composition, after carrying out proportioning and weighing, puts into ball mill jar;

[0039] (2) add deionized water and carry out ball milling, ball milling time 8 hours;

[0040](3) After ball milling, pour out the slurry and dry it at a temperature of 70-90°C for 24 hours;

[0041] (4) After drying, the powder is ground, shaped and sintered, the sintering temperature is set at 650° C., and the sintering time is 3 hours to obtain a sample, which is designated as Embodiment 1.

Embodiment 2

[0043] A method for preparing cesium garnet glass-ceramic by low-temperature liquid-phase sintering provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0044] (1) get solid raw material activation kaolin, boric acid, cesium hydroxide monohydrate and sodium hydroxide, according to the molar ratio of chemical element is Cs 0.4 Na 1.6 O·Al 2 o 3 4SiO2 2 0.9B 2 o 3 The composition, after carrying out proportioning and weighing, puts into ball mill jar;

[0045] (2) Add deionized water and carry out ball milling, and the ball milling time is 9 hours;

[0046] (3) After ball milling, pour out the slurry and dry it at a temperature of 70-90°C for 24 hours;

[0047] (4) After drying, the powder is ground, shaped and sintered. The sintering temperature is set at 750° C. and the sintering time is 4 hours to obtain a sample, which is designated as Embodiment 2.

Embodiment 3

[0049] A method for preparing cesium garnet glass-ceramic by low-temperature liquid-phase sintering provided by a preferred embodiment of the present invention, the specific steps are as follows:

[0050] (1) get solid raw material activation kaolin, boric acid, cesium hydroxide monohydrate and sodium hydroxide, according to the molar ratio of chemical element is Cs 1.8 Na 0.2 O·Al 2 o 3 ·6SiO2 2 1.2B 2 o 3 The composition, after carrying out proportioning and weighing, puts into ball mill jar;

[0051] (2) Add deionized water and carry out ball milling, and the ball milling time is 9 hours;

[0052] (3) After ball milling, pour out the slurry and dry it at a temperature of 70-90°C for 24 hours;

[0053] (4) After drying, the powder is ground, shaped and sintered, the sintering temperature is set at 950° C., and the sintering time is 4 hours to obtain a sample, which is designated as Embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com