Preparation method and application of a green manganese-doped silicate fluorescent material

A fluorescent material and manganese doping technology, applied in the field of fluorescent materials, can solve the problems of long afterglow time, short afterglow time, low absorption intensity, etc., and achieve the effects of low equipment requirements, simple preparation process and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a green manganese-doped silicate fluorescent material, the preparation of which includes the following steps:

[0044] (1) According to the chemical formula Zn 1.92 Mn 0.08 SiO 4 composition, reduce the ZnO in the experimental raw materials by 15% of its stoichiometric ratio, weigh 0.5983g ZnO, 0.0414g MnCO 3 , 0.2075gSiO 2 , grind for 30min, mix the raw materials evenly to obtain mixed powder;

[0045] (2) Put the mixed powder into a corundum crucible, put it into a tubular atmosphere furnace, raise the temperature to 800°C at a heating rate of 5°C / min, keep the temperature for 2 hours, and then raise the temperature to 1250 at a heating rate of 5°C / min. ℃, hold for 4h, then drop to 800°C at a rate of 5°C / min, hold for 2h, and finally drop to 500°C at a rate of 5°C / min, then cool to room temperature naturally, take out the obtained powder and grind it into powder. Obtain the desired phosphor material.

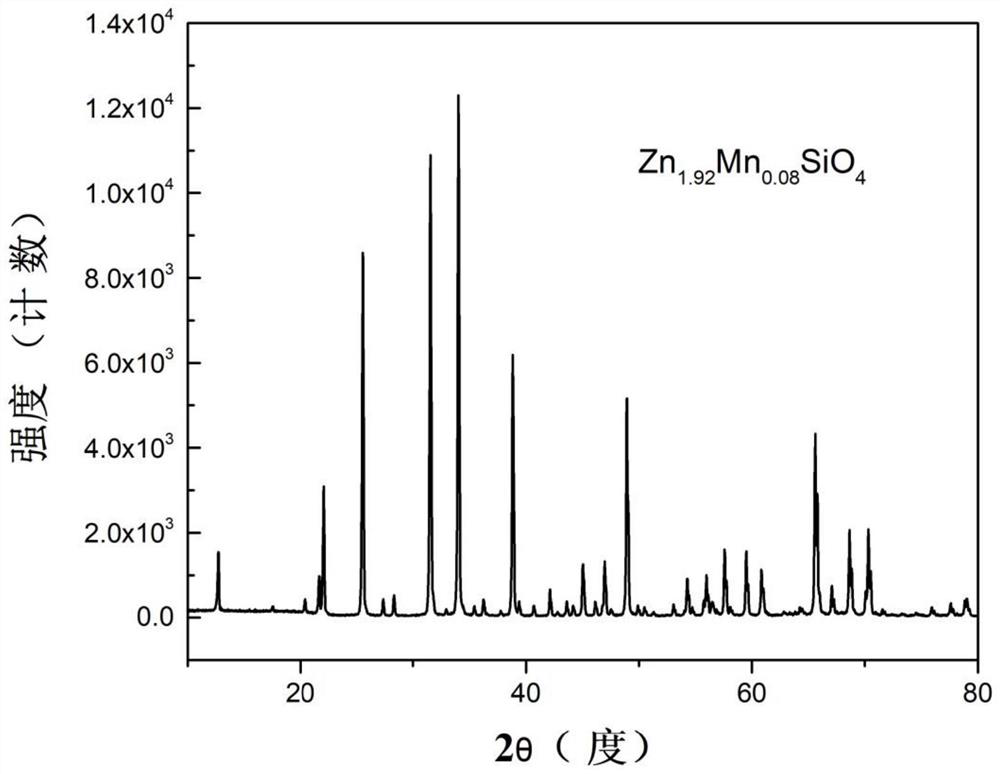

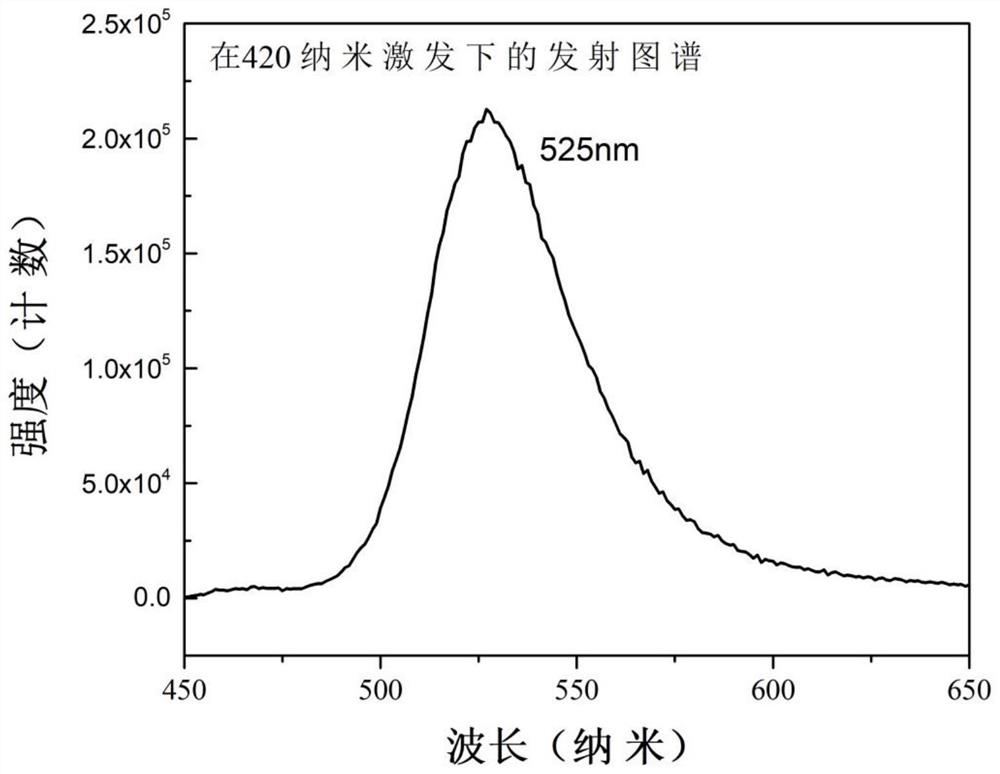

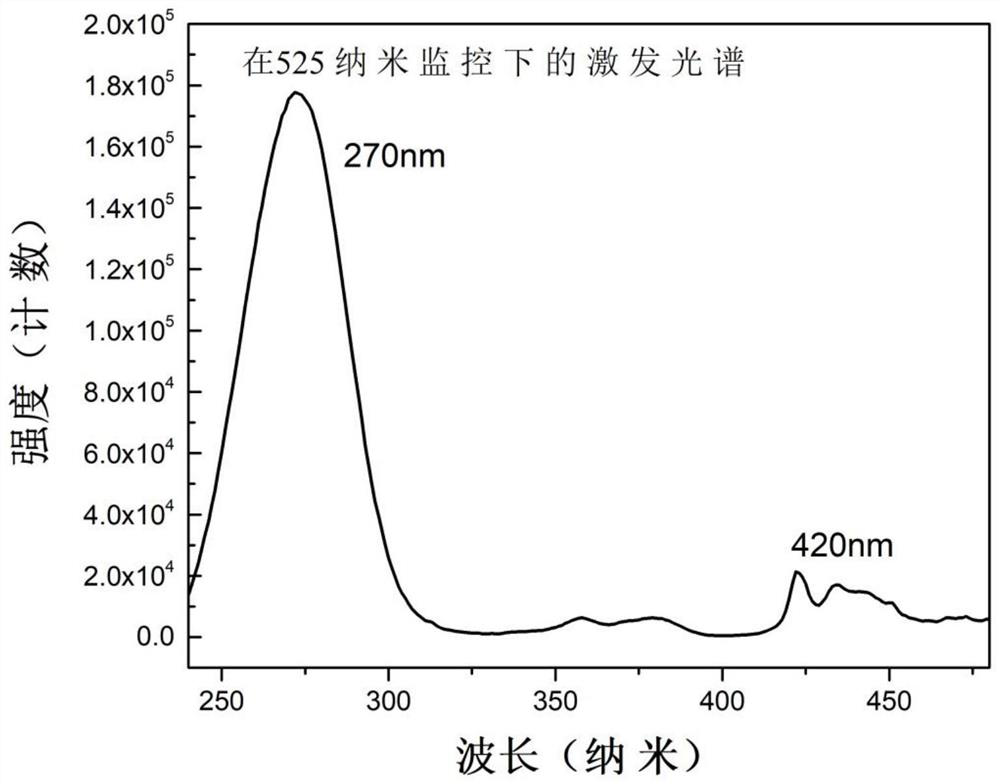

[0046] Figure 7 Shown is the XRD ...

Embodiment 2

[0048] This embodiment provides a green manganese-doped silicate fluorescent material, the preparation of which includes the following steps:

[0049] (1) According to the chemical formula Zn 1.92 Mn 0.08 SiO 3.9 N 0.1 composition, reduce the ZnO in the experimental raw materials by 15% of its stoichiometric ratio, weigh 0.5988g ZnO, 0.2505g SiO 2 , 0.0158gSi 3 N 4 and 0.0414gMnCO 3 , grind for 30min, mix the raw materials evenly to obtain mixed powder;

[0050] (2) Put the mixed powder into the corundum crucible, put it into the tube atmosphere furnace, and put it in the N 2 Under the atmosphere, the temperature was raised to 800°C at a heating rate of 5°C / min, kept for 2 hours, and then raised to 1250°C at a heating rate of 5°C / min, kept for 4 hours, and then a reducing gas H was introduced. 2 , drop to 800°C at a rate of 5°C / min, hold for 2 hours, and finally drop to 500°C at a rate of 5°C / min, then cool to room temperature naturally, take out the obtained powder an...

Embodiment 3

[0052] This embodiment provides a green manganese-doped silicate fluorescent material, the preparation of which includes the following steps:

[0053] (1) According to the chemical formula Zn 1.92 Mn 0.08 SiO 3.8 N 0.2 composition, reduce the ZnO in the experimental raw materials by 15% of its stoichiometric ratio, weigh 0.5993g ZnO, 0.2304g SiO 2 , 0.0317gSi 3 N 4 and 0.0415gMnCO 3 , grind for 30min, mix the raw materials evenly to obtain mixed powder;

[0054] (2) Put the mixed powder into the corundum crucible, put it into the tube atmosphere furnace, and put it in the N 2 Under the atmosphere, the temperature was raised to 800°C at a heating rate of 5°C / min, kept for 2 hours, and then raised to 1250°C at a heating rate of 5°C / min, kept for 4 hours, and then a reducing gas H was introduced. 2 , drop to 800°C at a rate of 5°C / min, hold for 2 hours, and finally drop to 500°C at a rate of 5°C / min, then cool to room temperature naturally, take out the obtained powder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com