Ionic liquid polymer gel electrolyte for solid-state lithium battery, and preparation method

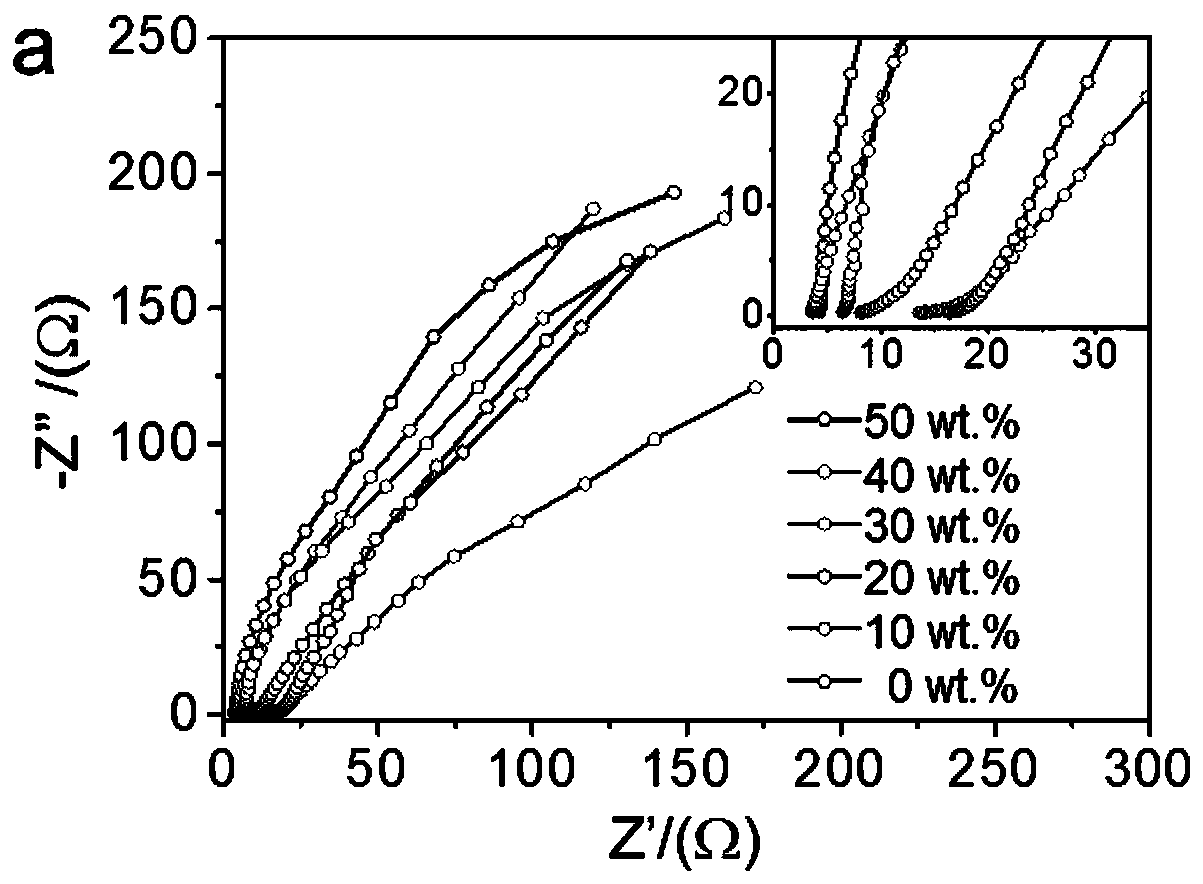

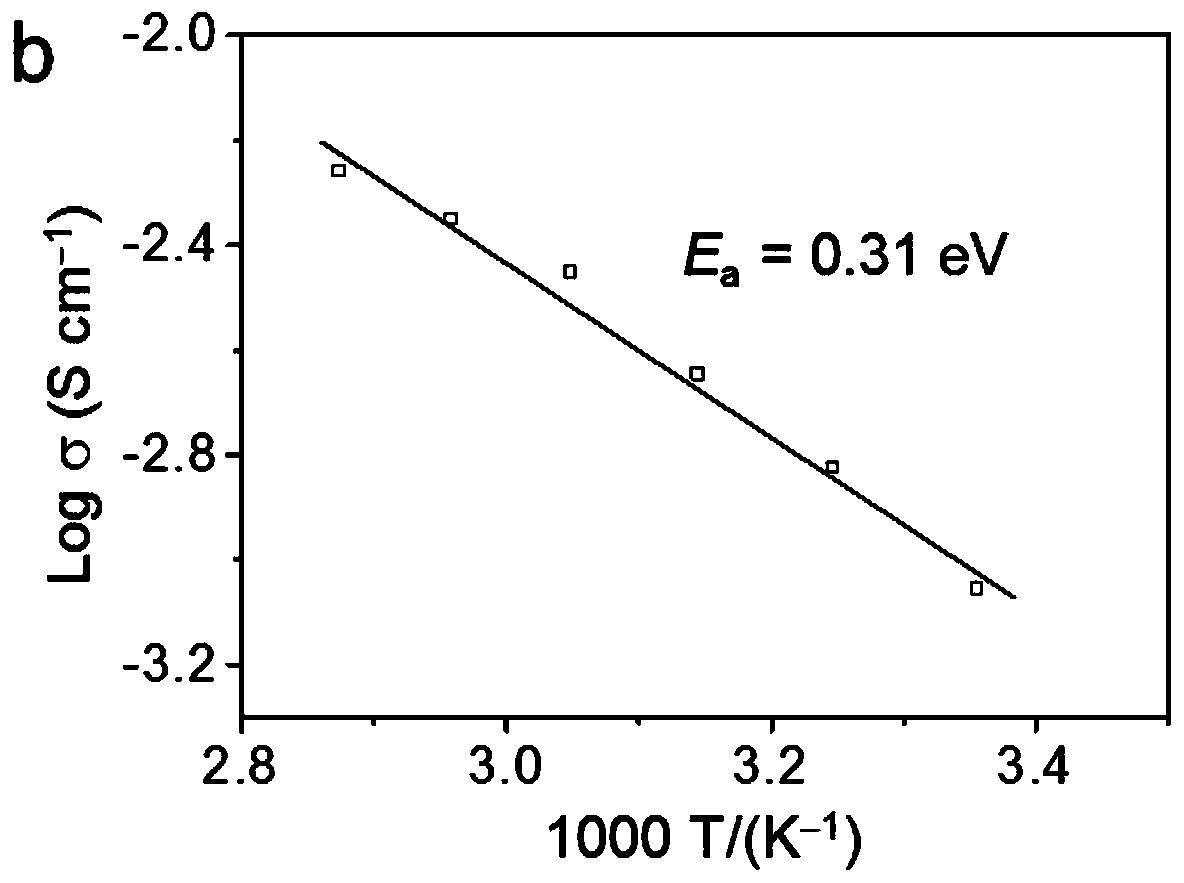

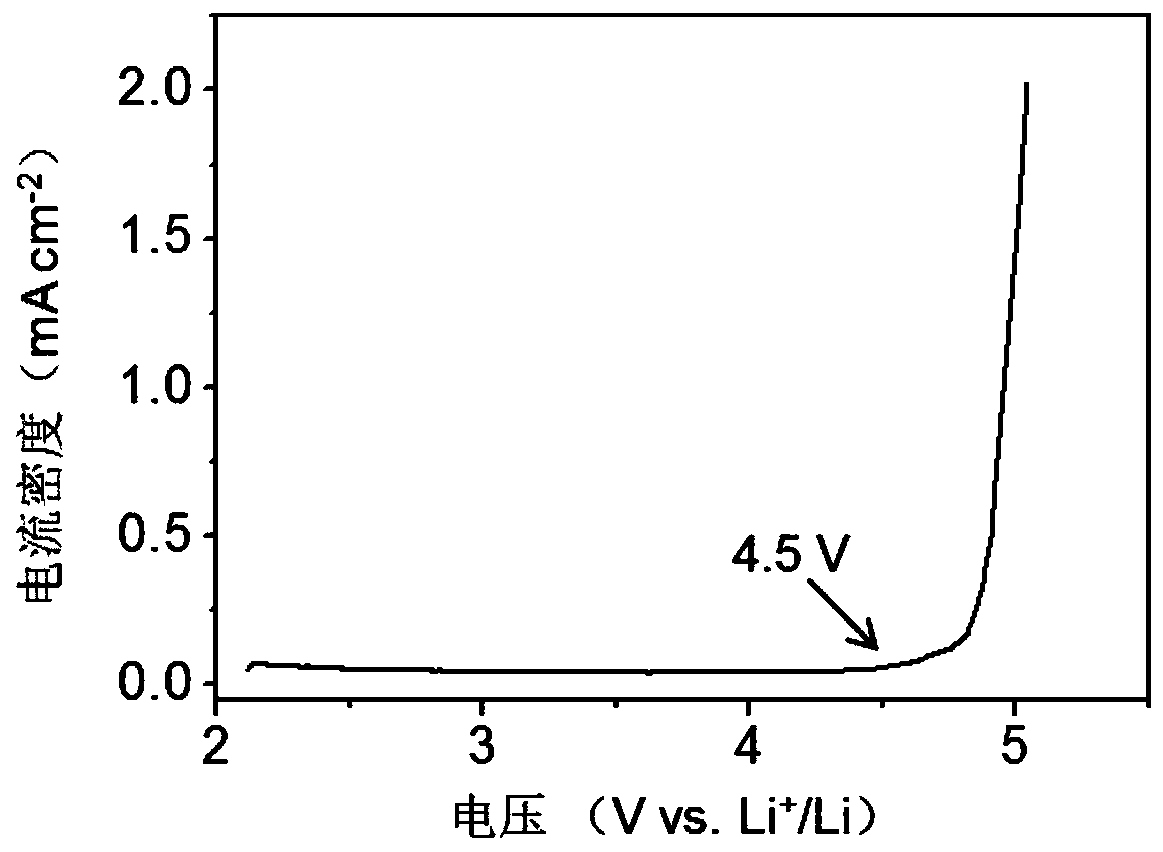

A technology of gel electrolyte and ionic liquid, which is applied in the field of electrochemical energy storage, can solve problems such as dendrite growth of metal lithium negative electrodes, and achieve good cycle performance and rate performance, and high room temperature ionic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of ionic liquid polymer gel electrolyte for solid-state lithium battery, its preparation method is as follows:

[0031] (1) 1g of polyvinylidene fluoride-hexafluoropropylene copolymer and 1g of 1-methyl-3-ethylimidazole bis(trifluoromethylsulfonyl)imide were dissolved in 5mL of anhydrous acetone, after stirring evenly, Apply a uniform film on the aluminum foil with a film maker;

[0032] (2) drying the aluminum foil coated with the film in vacuum for 6 hours at 50° C., then cooling, and peeling off to obtain the desired ionic liquid polymer film;

[0033] (3) Soak the ionic liquid polymer film in the 1,3-dioxolane / ethylene glycol dimethyl ether mixed solution of 1M bis(trifluoromethanesulfonate)imide lithium for 24 hours, after taking it out, use The excessive solvent is removed by filter paper, and the ionic liquid polymer gel electrolyte is obtained.

Embodiment 2

[0035] A kind of ionic liquid polymer gel electrolyte for solid-state lithium battery, its preparation method is as follows:

[0036] (1) Dissolve 1g of polyvinylidene fluoride-hexafluoropropylene copolymer and 0.25g of 1-methyl-3-ethylimidazole bis(trifluoromethylsulfonyl)imide in 5mL of anhydrous acetone, stir well , coated on aluminum foil with a film maker to form a uniform film;

[0037] (2) drying the aluminum foil coated with the film in vacuum for 6 hours at 50° C., then cooling, and peeling off to obtain the desired ionic liquid polymer film;

[0038] (3) Soak the ionic liquid polymer film in the 1,3-dioxolane / ethylene glycol dimethyl ether mixed solution of 1M bis(trifluoromethanesulfonate)imide lithium for 24 hours, after taking it out, use The excessive solvent is removed by filter paper, and the ionic liquid polymer gel electrolyte is obtained.

Embodiment 3

[0040] A kind of ionic liquid polymer gel electrolyte for solid-state lithium battery, its preparation method is as follows:

[0041] (1) Dissolve 1g of polyvinylidene fluoride-hexafluoropropylene copolymer and 0.5g of 1-methyl-3-ethylimidazole bis(trifluoromethylsulfonyl)imide in 5mL of anhydrous acetone, stir well , coated on aluminum foil with a film maker to form a uniform film;

[0042] (2) Under the condition of 55 ℃, vacuum-dry the aluminum foil coated with the film for 5 hours, then cool it down, and peel off to obtain the required ionic liquid polymer film;

[0043] (3) Soak the ionic liquid polymer film in the 1,3-dioxolane / ethylene glycol dimethyl ether mixed solution of 1M bis(trifluoromethanesulfonate)imide lithium for 23 hours, after taking it out, use The excessive solvent is removed by filter paper, and the ionic liquid polymer gel electrolyte is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com