Solid non-polarized electrode resistant to deep sea pressure and preparation method thereof

A polarized electrode, solid technology, applied in the field of materials, can solve the problems of weak resistance to mechanical vibration, different environments and performances, short electrode stability period, etc., to improve deep-sea high voltage resistance, excellent electrical performance, improve The effect of electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

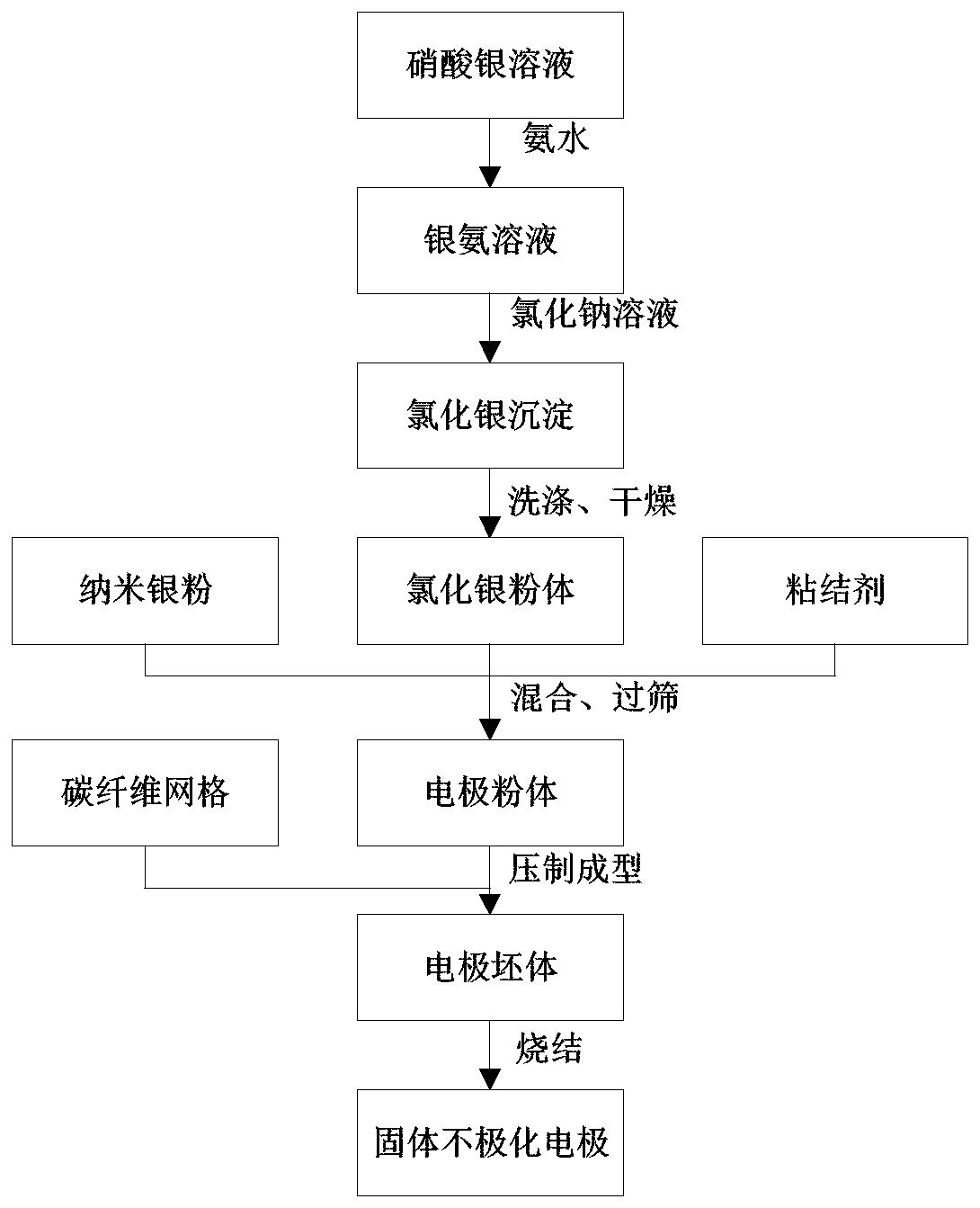

[0020] Please refer to figure 1 , an embodiment of the present invention provides a method for preparing a solid non-polarized electrode resistant to deep-sea pressure, comprising the following steps:

[0021] Step S1, first dissolving silver nitrate in deionized water to prepare a silver nitrate solution, then adding a small amount of ammonia water to the solution to obtain a brown precipitate, adding excess dilute ammonia water to dissolve the brown precipitate to obtain a silver ammonia solution;

[0022] Step S2, fully mixing the sodium chloride solution and the silver ammonia solution according to a mass ratio of 1:2.0 to 1:3.5 to obtain silver chloride precipitation;

[0023] In step S3, the silver chloride precipitate is repeatedly washed, freeze-dried or spray-dried to obtain nano-silver chloride powder;

[0024] Step S4, mixing the nano-silver powder and the above-mentioned silver chloride powder according to the mass ratio of 1:0.8 to 1:2.5, and then adding a binder...

Embodiment 1

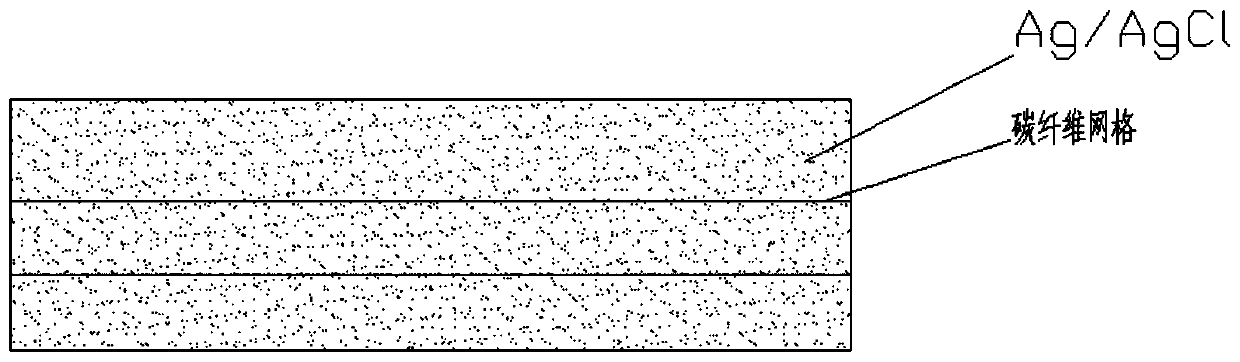

[0029] Take by weighing 11.85g silver nitrate, be dissolved in deionized water, make 0.2mol / L silver nitrate solution, add ammonia solution, generate brown precipitate, continue to add excessive dilute ammonia water to make brown precipitate just dissolve, obtain silver ammonia solution; Weigh 4.08 g sodium chloride to obtain a 0.2mol / L sodium chloride solution, pour the sodium chloride solution into the silver ammonia solution, and stir rapidly to obtain a silver chloride precipitate; the silver chloride precipitate is repeatedly washed and dried by spray drying , to obtain silver chloride powder; weigh 8g silver chloride powder and 10g silver powder, add polyvinyl alcohol, fully mix, sieve, the sieve hole is 60 mesh, obtain electrode powder; electrode powder and carbon fiber grid Alternately placed in a mold, shaped under a pressure of 100MPa, and then sintered at 400°C for 1 hour under a nitrogen atmosphere to obtain a solid non-polarized electrode.

Embodiment 2

[0031] Weigh 10g of silver nitrate, dissolve it in deionized water to obtain a 0.2mol / L silver nitrate solution, add ammonia solution to form a brown precipitate, continue to add excess dilute ammonia to dissolve the brown precipitate, and obtain a silver ammonia solution; weigh 2.86g Sodium chloride, make 0.2mol / L sodium chloride solution, pour sodium chloride solution into silver ammonia solution, stir rapidly, obtain silver chloride precipitation; Silver chloride precipitation is washed repeatedly, dry with freeze-drying, Obtain silver chloride powder; weigh 5g silver chloride powder and 4g silver powder, add cellulose, fully mix, sieve, the sieve hole is 100 mesh, obtain electrode powder; place electrode powder and carbon fiber mesh alternately Molded in a mold under a pressure of 200MPa, and then sintered at 500°C for 2 hours under the protection of helium to obtain a solid non-polarized electrode.

[0032] refer to Figure 4 , which is the electrode typical range and ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com