Ordered germanium nanowires on silicon substrate and its preparation method and application

A germanium nanowire and silicon substrate technology, applied in the field of materials, can solve the problems of incompatibility, complex germanium nanowire-assisted transfer and arrangement technology, affecting device performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This example is used to illustrate the ordered germanium nanowires and the preparation method thereof of the present invention.

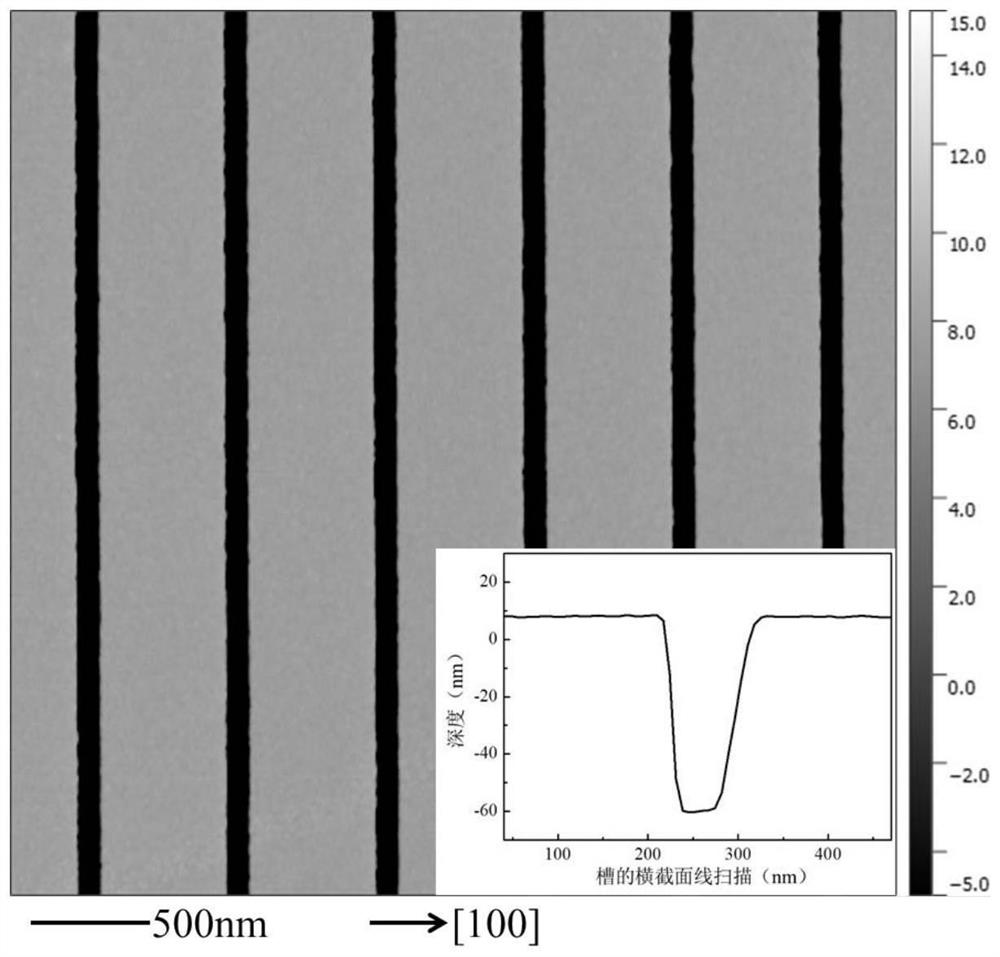

[0048] (1) Obtain a periodic groove structure on a silicon (001) substrate:

[0049] Spin-coat resist (PMMA) on the surface of silicon (001) substrate; use electron beam exposure technology to form a periodic groove structure along the [100] or [010] direction on the resist; use inductively coupled plasma The periodic groove structure is transferred to the silicon (001) substrate by bulk reactive ion etching technology; the residual resist on the substrate surface is removed by oxygen plasma.

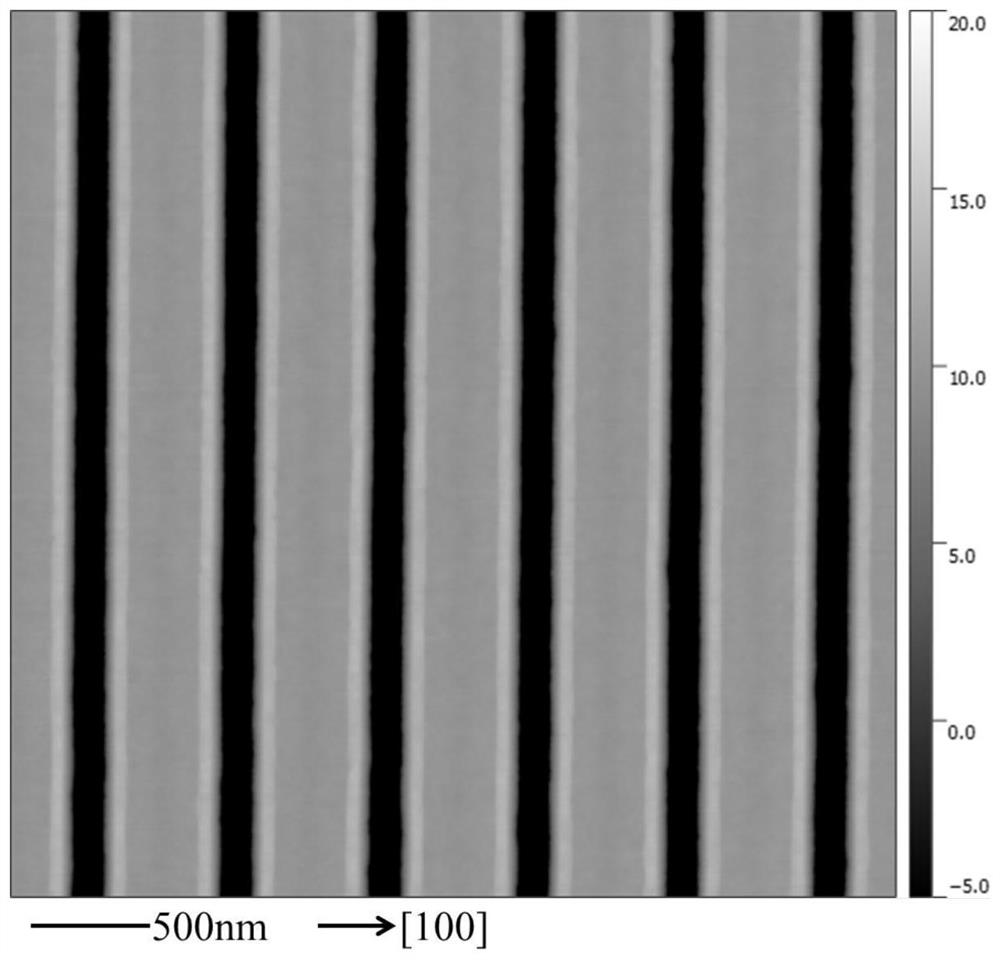

[0050] (2) Using molecular beam epitaxy growth technology to epitaxially grow a 3nm silicon germanium layer on a silicon (001) substrate with a periodic groove structure, the content of germanium is 25%, and the growth temperature is 550 ° C. On the edge of each groove An ordered trapezoidal linear structure is formed.

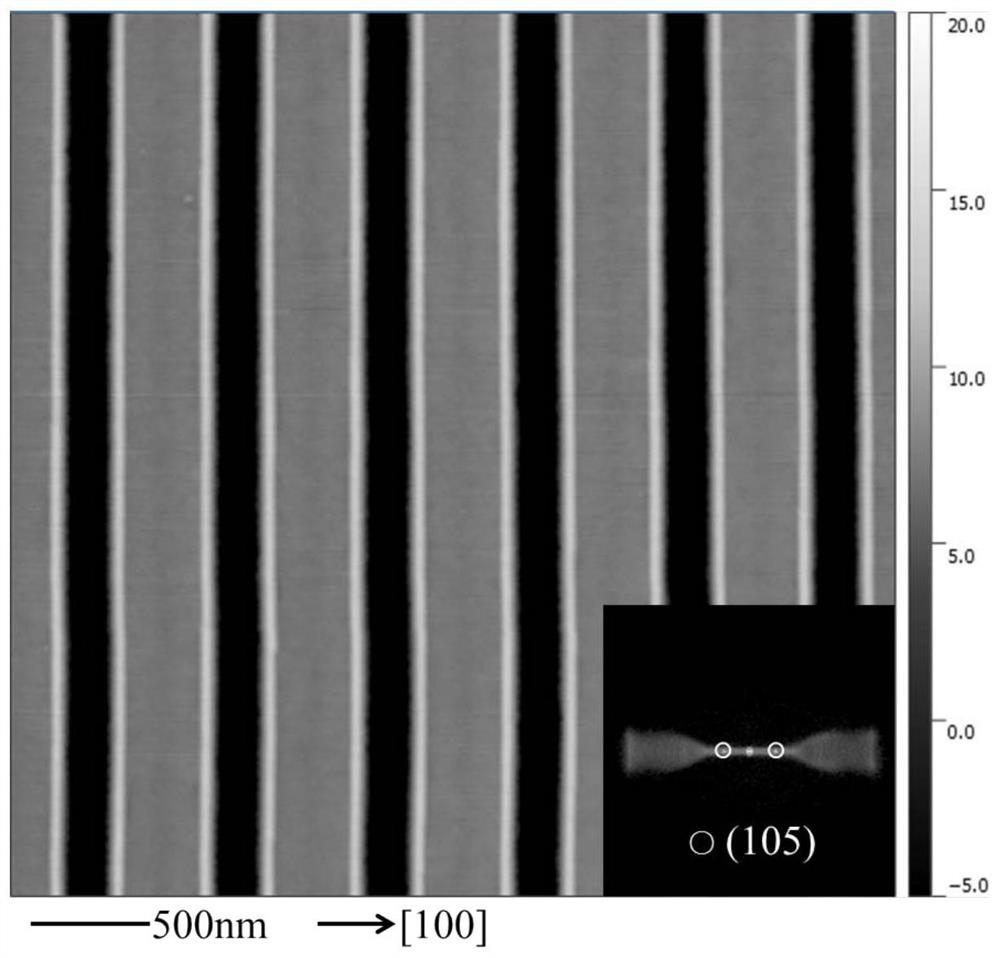

[0051] (3) A 0.6nm pure germani...

Embodiment 2

[0059] This example is used to illustrate the ordered germanium nanowires and the preparation method thereof of the present invention.

[0060] (1) Obtain a periodic groove structure on a silicon (001) substrate:

[0061] Spin-coat resist (PMMA) on the surface of silicon (001) substrate; use electron beam exposure technology to form a periodic groove structure along the [100] or [010] direction on the resist; use inductively coupled plasma The periodic groove structure is transferred to the silicon (001) substrate by bulk reactive ion etching technology; the residual resist on the substrate surface is removed by oxygen plasma.

[0062] (2) Using molecular beam epitaxy growth technology to epitaxially grow a 5nm silicon germanium layer on a silicon (001) substrate with a periodic groove structure, the content of germanium is 20%, and the growth temperature is 540 ° C. On the edge of each groove An ordered trapezoidal linear structure is formed.

[0063] (3) Using molecular be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com