Oxidation-state semi-regenerative reforming catalyst and preparation method thereof

A reforming catalyst, semi-regeneration technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Due to the large particle size of platinum atom clusters, the effect of not easy to aggregate, high selectivity, and enhanced interaction is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

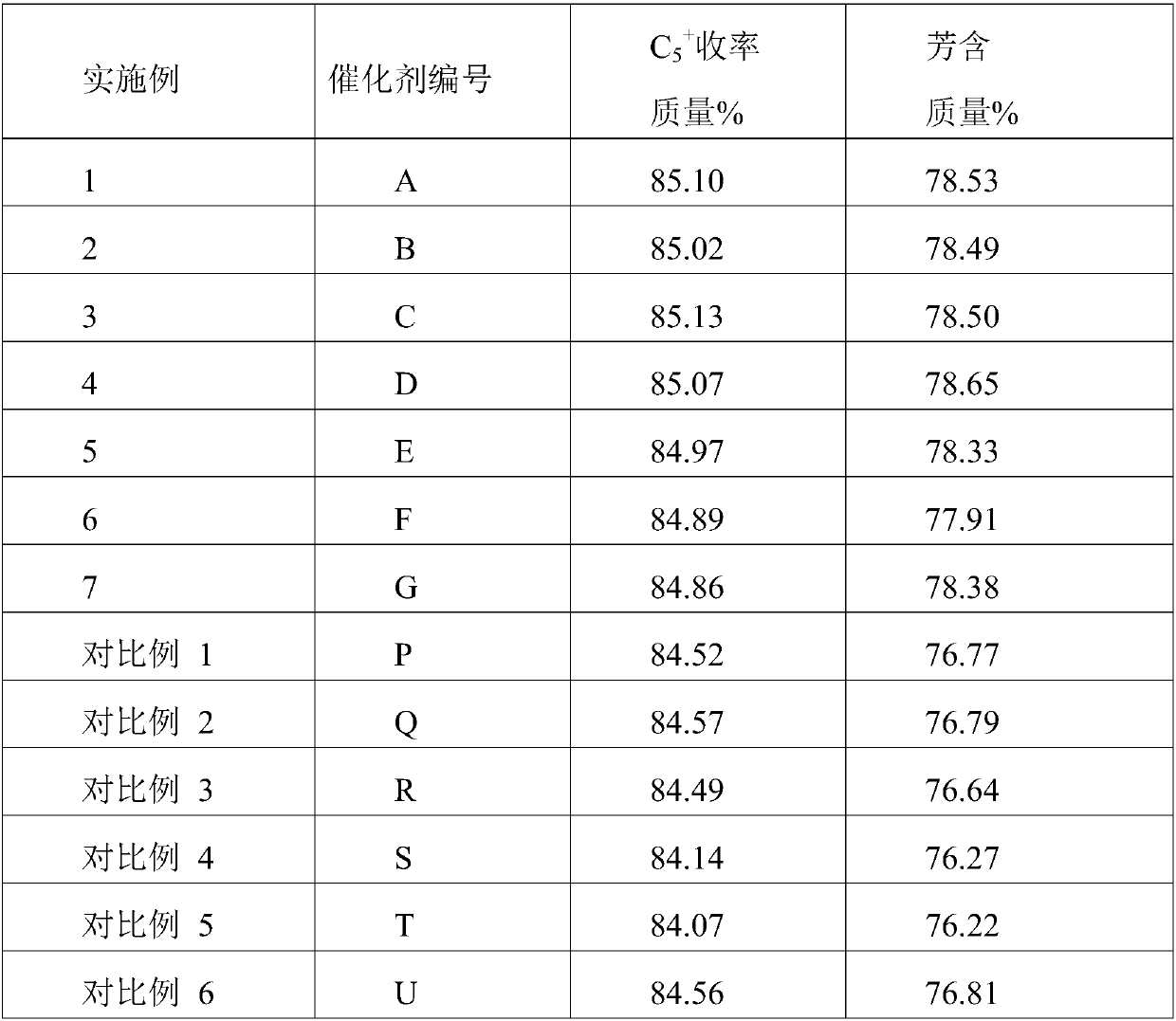

Examples

preparation example Construction

[0029] A method for preparing a semi-regenerated reforming catalyst, comprising the steps of:

[0030] Step 1, preparing alumina carrier;

[0031] Step 2, preparing an impregnating solution, which contains a platinum compound, a rhenium compound, a competing adsorbent and a nitrogen-containing compound;

[0032] Step 3, impregnating the alumina carrier and evaporating the impregnating solution to dryness at a temperature of 50-60°C; and

[0033] Step 4, the catalyst is dried and activated.

[0034] In the preparation method of the semi-regenerated reforming catalyst of the present invention, in step 1, the carrier is preferably γ-alumina, more preferably γ-alumina prepared from high-purity aluminum hydroxide obtained by hydrolysis of aluminum alkoxide. The catalyst carrier can be shaped by the usual methods of dropping balls, rolling balls, and extruding strips. commonly used.

[0035] The preparation method of the semi-regenerative reforming catalyst of the present invent...

Embodiment 1

[0046] Get 300 grams of pseudo-boehmite powder (manufactured by Sasol Company), and 6 grams of fennel powder, and mix them evenly. Get 4 grams of nitric acid with a concentration of 65% by mass, 7 grams of acetic acid with a concentration of 36% by mass, and 210 grams of deionized water after mixing to form a peptizer, pour the peptizer into the mixed pseudoboehmite powder, and knead To be suitable for extruding, after extruding, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere to obtain a strip-shaped γ-alumina carrier.

[0047] Prepare impregnating solution containing chloroplatinic acid, perrhenic acid, hydrochloric acid, and urea according to a predetermined amount, and the contents of platinum, rhenium, HCl and urea in the impregnating solution are respectively 0.25%, 0.45%, and 1.5% relative to the mass of alumina on a dry basis and 4.6%. Take the impregnating liquid to impregnate the carrier prepared in the pr...

Embodiment 2

[0049] Catalyst B was prepared according to the method of Example 1, except that the contents of platinum, rhenium, HCl and urea in the impregnating solution were 0.23%, 0.24%, 1.9% and 2.2% respectively relative to the mass of alumina on a dry basis. The liquid / solid ratio of the impregnating liquid to the carrier is 1.1, the impregnating temperature is 15°C, and the impregnating time is 0.5 hours. Specifically:

[0050] Get 300 grams of pseudo-boehmite powder (manufactured by Sasol Company), and 6 grams of fennel powder, and mix them evenly. Get 4 grams of nitric acid with a concentration of 65% by mass, 7 grams of acetic acid with a concentration of 36% by mass, and 210 grams of deionized water after mixing to form a peptizer, pour the peptizer into the mixed pseudoboehmite powder, and knead To be suitable for extruding, after extruding, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere to obtain a strip-shaped γ-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com