Preparation and application of a chitosan-modified microporous polymer nanomaterial

A technology of microporous polymers and nanomaterials, applied in the direction of analyzing materials, electrochemical variables of materials, and material analysis through electromagnetic means, etc., can solve the problem of inability to achieve ONOO-real-time monitoring, complex pretreatment, time-consuming and high cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

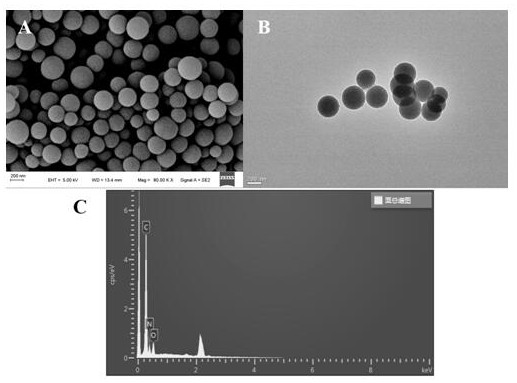

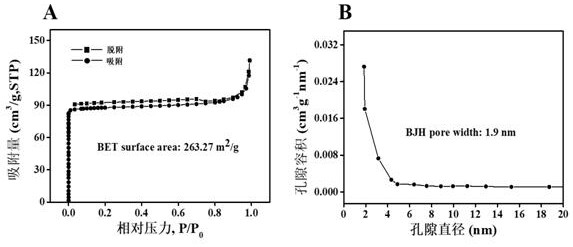

[0036] The preparation of the microporous polymer nanomaterial CTS-MPNS of embodiment 1, chitosan modification

[0037] Take 0.3g of m-aminophenol, add it into the reaction container with the mixed solution (60ml of ultrapure water and 30ml of absolute ethanol), stir magnetically at 32°C until it is completely dissolved, add 0.6ml of ammonia water (25%), and stir for 15 minutes Add 0.3ml formaldehyde, stir until a milky white suspension appears, continue to stir for 2 hours; then add 20ml mass concentration of 0.2% chitosan acetic acid solution (0.2g chitosan dissolved in 1% acetic acid solution) and stir for 3 hours; After cooling to room temperature, the obtained product was centrifuged and washed several times with ultrapure water (to remove unreacted formaldehyde), dried in vacuum at 60°C for 24 hours, and ground to obtain the chitosan-modified microporous polymer nanomaterial CTS-MPNS.

Embodiment 2

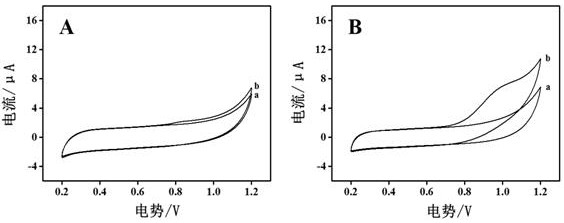

[0038] Embodiment 2, preparation of modified electrode CTS-MPNS / GCE

[0039] (1) Pretreatment of the glassy carbon electrode: the glassy carbon electrode is polished into a mirror surface with 0.30 μm and 0.05 μm Al2O3 suspension in sequence, and then ultrasonically cleaned with 95% ethanol and double distilled water in sequence , to obtain the treated glassy carbon electrode; then use the glassy carbon electrode as the working electrode, the platinum column as the counter electrode, and the saturated calomel electrode as the reference electrode in a three-electrode system. M potassium chloride electrolyte solution, carry out cyclic voltammetry scanning (scanning speed is 50mV / s), finally take out the electrode and rinse with twice distilled water and dry;

[0040] (2) Preparation of the modified electrode CTS-MPNS / GCE: Take 0.003 g of the chitosan-modified microporous polymer nanomaterial CTS-MPNS prepared in Example 1, and disperse it in 3 ml of water to make a concentration...

Embodiment 3

[0041] Example 3. Modified electrode CTS-MPNS / GCE detects ONOO in the solution - concentration

[0042] The modified electrode CTS-MPNS / GCE is used as the working electrode, the platinum column is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode to form a three-electrode system. - The 0.2M phosphate buffer solution with pH=7.0 was used as the electrolyte, and the scanning was carried out by chronoamperometry under the working potential of 1.1V. According to the response current Ip and ONOO - Linear regression equation for concentration: Ip (μA) = 0.0698 [ONOO - ] + 0.2039 calculates ONOO - concentration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com